Russian Customer Visit: Baffle Ceiling Making Machine

2025-11-11 17:00

“KINGREAL CEILING MACHINERY welcomes customers from all over the world to visit our factory and tour our various machines. By allowing customers to operate the machines themselves and inspect the finished products, they can truly experience the superior performance of KINGREAL CEILING MACHINERY machines. This is also an important step in building trust and a cooperative relationship between customers and KINGREAL CEILING MACHINERY.”

Recently, KINGREAL CEILING MACHINERY welcomed a customer from Russia. To give the customer a comprehensive understanding of KINGREAL CEILING MACHINERY baffle ceiling making machines, KINGREAL CEILING MACHINERY staff specially invited him to the KINGREAL CEILING MACHINERY factory to tour the baffle ceiling machine. The hope was that through hands-on experience and inspection of the finished products, the Russian customer could evaluate the performance of the KINGREAL CEILING MACHINERY baffle ceiling making machines and confirm whether they met his project requirements. Accompanied by KINGREAL CEILING MACHINERY staff, the Russian customer arrived at the KINGREAL CEILING MACHINERY factory. KINGREAL CEILING MACHINERY staff first led the customer to the baffle ceiling machine debugging workshop. Here, KINGREAL CEILING MACHINERY engineers provided a detailed explanation, ensuring the Russian customer understood the performance and function of each baffle ceiling making machine component. |  |

| During the baffle ceiling machine demonstration, the KINGREAL CEILING MACHINERY engineer first set the production speed of the baffle ceiling making machine to the maximum of 30m/min. They introduced the KINGREAL CEILING MACHINERY baffle ceiling machine to the Russian customer, explaining its ability to produce U-shaped and V-shaped square tube ceiling panels. KINGREAL CEILING MACHINERY engineers also detailed the common specifications of finished products produced by the baffle ceiling making machine: lengths from 600mm to 4000mm, widths from 25mm to 100mm, and heights from 75mm to 300mm. More importantly, the Russian customer learned that the baffle ceiling machine can process various materials, including aluminum, steel, iron, galvanized sheet, and roll-coated sheet. Iron sheet thickness ranges from 0.4-0.7mm, while aluminum sheet thickness ranges from 0.3-1.0mm. This professional explanation gave the Russian customer a deeper understanding of the baffle ceiling making machine. |

The Russian customer asked several design-related questions throughout the visit about the baffle ceiling making machine. For instance, he asked about including safety devices on the baffle ceiling making machine, and KINGREAL CEILING MACHINERY staff immediately offered a solution recommending fitting the baffle ceiling machine with a protective shield to guarantee operational safety. Talking about methods to enhance the automatic operation of the baffle ceiling making machine, KINGREAL CEILING MACHINERY engineers suggested mounting a feeding trolley to the decoiler to automatically introduce great rolls of material into the decoiler. The Russian customer approved of the suggestions, believing that these improvements would significantly increase the baffle ceiling machine's production efficiency. This series of interactions impressed the Russian customer with the professionalism and rapid response of KINGREAL CEILING MACHINERY staff. They not only answered customer questions promptly but also adjusted the baffle ceiling making machine according to the customer's specific needs. This professional service fostered trust in KINGREAL CEILING MACHINERY among the Russian customer.

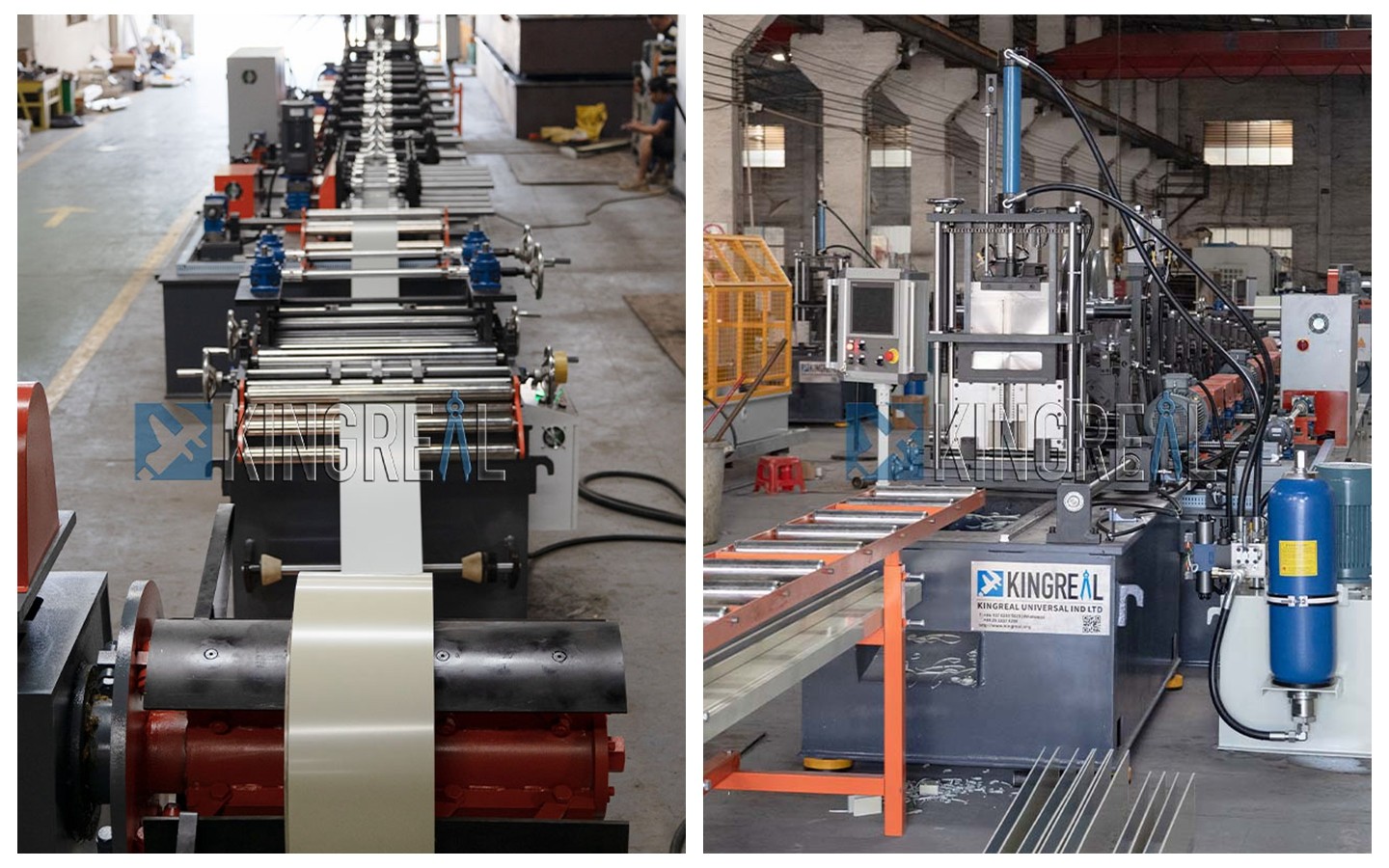

Photos About Baffle Ceiling Machine:

During the factory visit, the meticulous and attentive attitude of KINGREAL CEILING MACHINERY staff greatly satisfied the Russian customer. Since this Russian customer had relatively little knowledge of baffle ceiling machines, KINGREAL CEILING MACHINERY staff patiently explained all the baffle ceiling making machine's components. This one-on-one explanation enabled the Russian customer to quickly grasp the basics of baffle ceiling machines and understand how to use them according to their own needs. During the visit, KINGREAL CEILING MACHINERY engineering team demonstrated solid professional knowledge and technical capabilities. They answered the Russian customer's inquiries swiftly and correctly, providing comprehensive information to assist the customer in better understanding the benefits and uses of the baffle ceiling making machine. For instance, when a Russian customer asked how to maximize manufacturing efficiency, KINGREAL CEILING MACHINERY engineers were able to provide answers using particular data and case studies, therefore inspiring confidence in the customer's conviction in the future uses of baffle ceiling machine.

Photos About Baffle Ceiling Machine:

Furthermore, the Russian customer also showed great pleasure with KINGREAL CEILING MACHINERY one-stop service. KINGREAL CEILING MACHINERY staff accompanied the customer throughout the visit, allowing them to freely tour the factory. Whether inspecting the quality of raw materials or exploring the baffle ceiling making machine manufacturing and debugging workshops, KINGREAL CEILING MACHINERY employees provided detailed answers. The Russian customer experienced not only the baffle ceiling machine's performance but also the comprehensiveness of KINGREAL CEILING MACHINERY service.

Following the tour, KINGREAL CEILING MACHINERY staff approached us to present the services KINGREAL CEILING MACHINERY provides, including machine installation, operational training, routine maintenance, and spare part supply. The Russian customer found comfort from this all-inclusive assistance from purchase to after-sales care.

This factory visit not only enhanced the Russian customer's understanding of KINGREAL CEILING MACHINERY and baffle ceiling making machines but also allowed them to experience the service spirit and technical strength of the KINGREAL CEILING MACHINERY professional team. From detailed explanations and rapid response to one-stop service, KINGREAL CEILING MACHINERY demonstrated its competitive advantages in the industry, winning the trust and recognition of its customers. Looking ahead, KINGREAL CEILING MACHINERY hopes to establish partnerships with more customers, providing them with efficient and reliable baffle ceiling machines and excellent service.

Get the latest price? We'll respond as soon as possible(within 12 hours)