Technological Advancements in Facade Panel Roll Forming Machine

2025-10-29 17:00

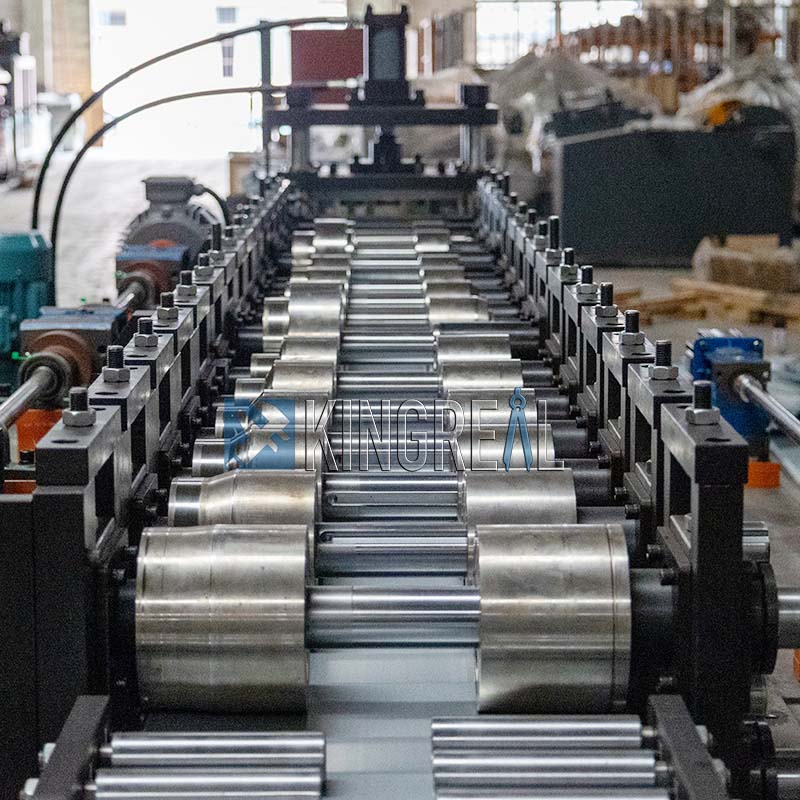

Modern structures are employing metal wall panels more and more as the construction sector grows quickly. An essential construction material, metal wall panels help to increase building energy efficiency as well as have great visual appeal and strength. Using cutting-edge roll forming techniques, KINGREAL CEILING MACHINERY facade panel roll forming machines focus on creating facade wall cladding panels for walls and outside walls. to correctly cut metal coils into several profiles. Residential and commercial structures use these metal wall panels extensively to improve their visual appeal and successfully withstand the impact of several external influences. Hence, ongoing technical developments in facade wall cladding panel machine have been driven by the market demand for premium, expandable, and customizable metal wall panel systems.

In 2025, KINGREAL CEILING MACHINERY comprehensively upgraded facade wall cladding panel machine manufacturing technology, providing customers with higher productivity, lower costs, and superior finished product quality. Whether for manufacturers, contractors, or suppliers in the construction industry, the newly upgraded KINGREAL CEILING MACHINERY facade panel roll forming machines will bring them greater precision, speed, and cost-effectiveness.

Technological Advancements in Facade Wall Cladding Panel Machine

1. Artificial intelligence technology for facade panel roll forming machine

In modern manufacturing, the application of artificial intelligence technology is becoming increasingly widespread. KINGREAL CEILING MACHINERY facade wall cladding panel machines utilize advanced AI algorithms that monitor the production process in real time, identify potential defects, and optimize facade panel roll forming machine performance. This technology ensures consistent quality in every metal wall panel produced. Furthermore, the AI system can detect faults early, reducing waste in the production process and improving overall production efficiency. This intelligent production method gives facade wall cladding panel machines a competitive edge in the market.

2. Internet of things monitoring system for facade panel roll forming machine

The introduction of IoT sensors enables facade wall cladding panel machines to collect data on machine operation, material usage, and output. This information helps operators to conduct remote monitoring and predictive maintenance, therefore lowering unanticipated failure-related downtime. Furthermore, these sensors can be easily integrated with Industry 4.0 intelligent manufacturing systems, hence enhancing the whole manufacturing process's effectiveness and intelligence.

3. Advanced material processing capabilities for facade panel roll forming machine

KINGREAL CEILING MACHINERY facade wall cladding panel machines can process a larger variety of materials, including pre-coated sheets and composite metals. This ability helps companies to satisfy the needs of several markets, hence promoting the manufacture of lightweight and corrosion-resistant panels. Whether for functional or decorative cladding uses, this flexibility makes facade panel roll forming machines a great option for several sectors.

4. Servo control precision for facade panel roll forming machine

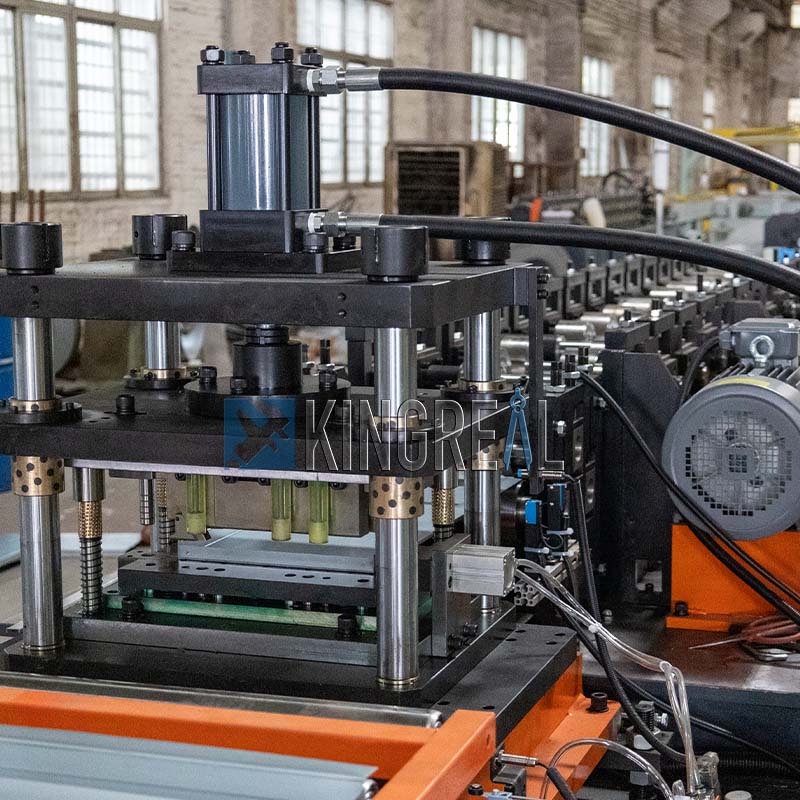

The upgrade to facade wall cladding panel machines is also reflected in the application of a servo control system. Equipped with servo motors, the facade panel roll forming machine's roller positioning, cutting system, and punching unit all achieve precise control. This precision not only ensures perfect dimensions and a smooth surface for the wall panels but also enhances the structural integrity of the metal wall panels. Simultaneously, the application of the servo control system effectively reduces facade wall cladding panel machine operating energy consumption, improving overall economic efficiency.

5. Modular tooling system for facade panel roll forming machine

KINGREAL CEILING MACHINERY facade wall cladding panel machines employ a modular tooling system. This design allows manufacturers to quickly switch between different panel designs and sizes. Operators simply input different production parameters on the control panel, eliminating the need for cumbersome equipment adjustments and minimizing downtime during production changes. This flexibility allows manufacturers to better meet diverse customer needs and simplify the production process for customized profiles.

6. Automated packaging system for facade panel roll forming machine

To more increase production efficiency, KINGREAL CEILING MACHINERY facade wall cladding panel machines can also be fitted with automated stacking and packaging solutions. Simplifying post-processing, this mechanism reduces labor needs and guarantees the safety and efficiency of completed panels when handled. By means of automated packaging, the facade panel roll forming machine not only increases total operating efficiency but also lowers labor costs, therefore increasing the financial advantages for companies.

Advantages of Facade Wall Cladding Panel Machine

1. Versatile facade panel roll forming machine

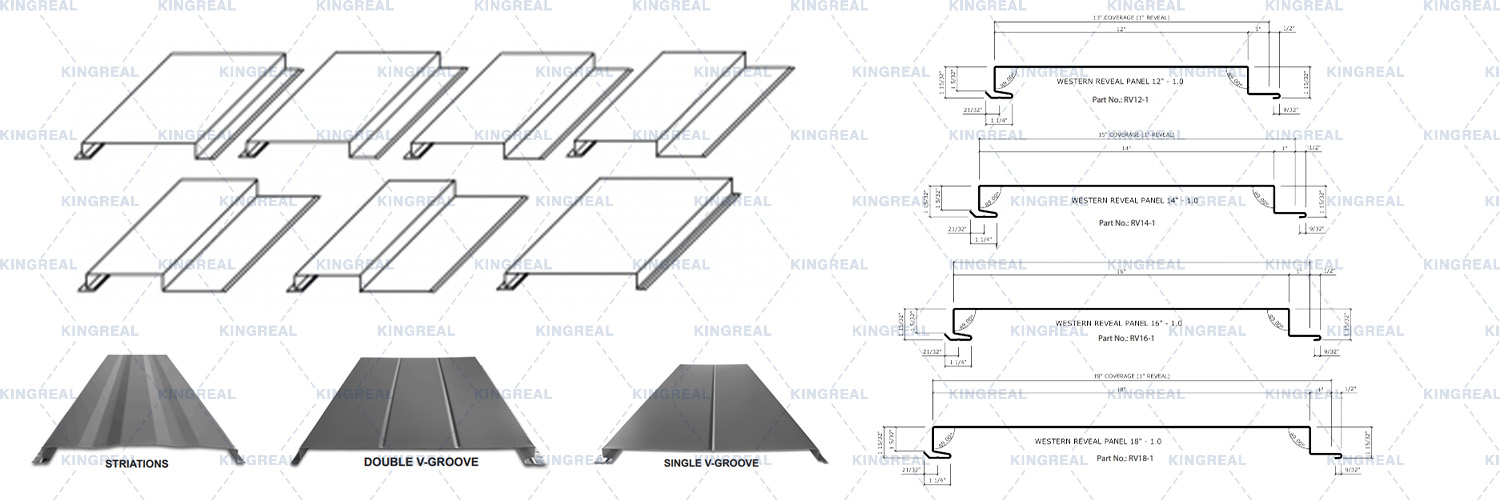

KINGREAL CEILING MACHINERY facade wall cladding panel machines can produce various types of metal wall panels, including corrugated sheets, trapezoidal panels, and interlocking designs. Customers can choose the appropriate machine based on their project requirements.

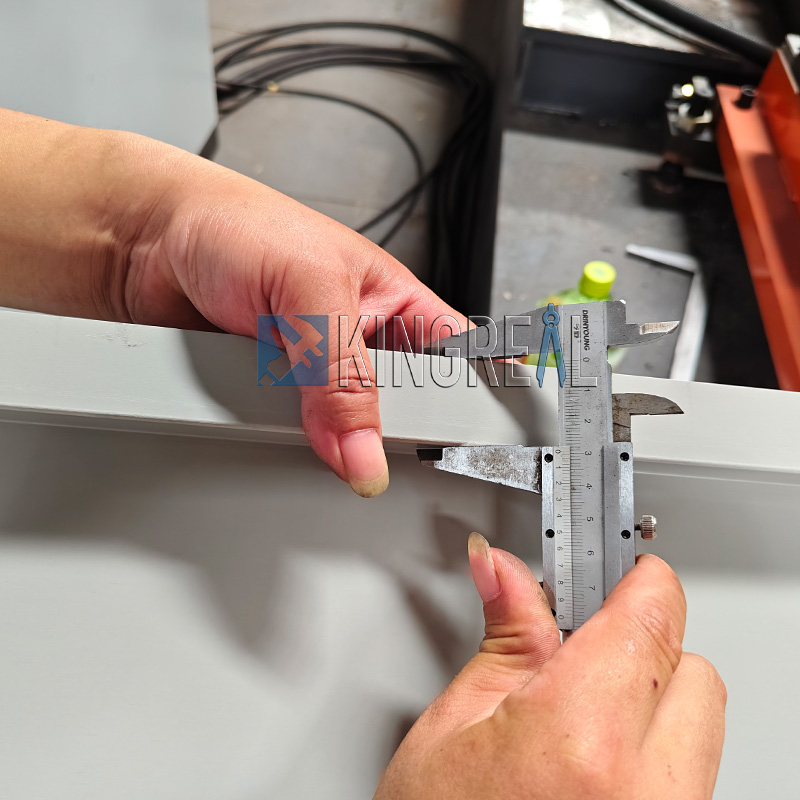

2. High precision and tolerances for facade wall cladding panel machine

Through advanced manufacturing technology, KINGREAL CEILING MACHINERY facade panel roll forming machines guarantee high precision and tolerances in the finished products. This precision not only ensures seamless installation but also enhances the professional appearance of the finished product, meeting the construction industry's dual requirements for aesthetics and functionality.

3. Multi-specification and multi-size production for facade panel roll forming machine

KINGREAL CEILING MACHINERY facade wall cladding panel machine supports the production of multiple specifications and sizes. This feature allows customers to flexibly adjust production plans according to project needs, meet the demands of different markets, and further enhance product competitiveness.

Drawing About Facade Panel

If you need more information about the facade panel roll forming machine, please feel free to contact KINGREAL CEILING MACHINERY!

Get the latest price? We'll respond as soon as possible(within 12 hours)