What is HVAC Spiral Duct Making Machine?

2025-05-02 17:00

Introduction of HVAC Spiral Duct Making Machine

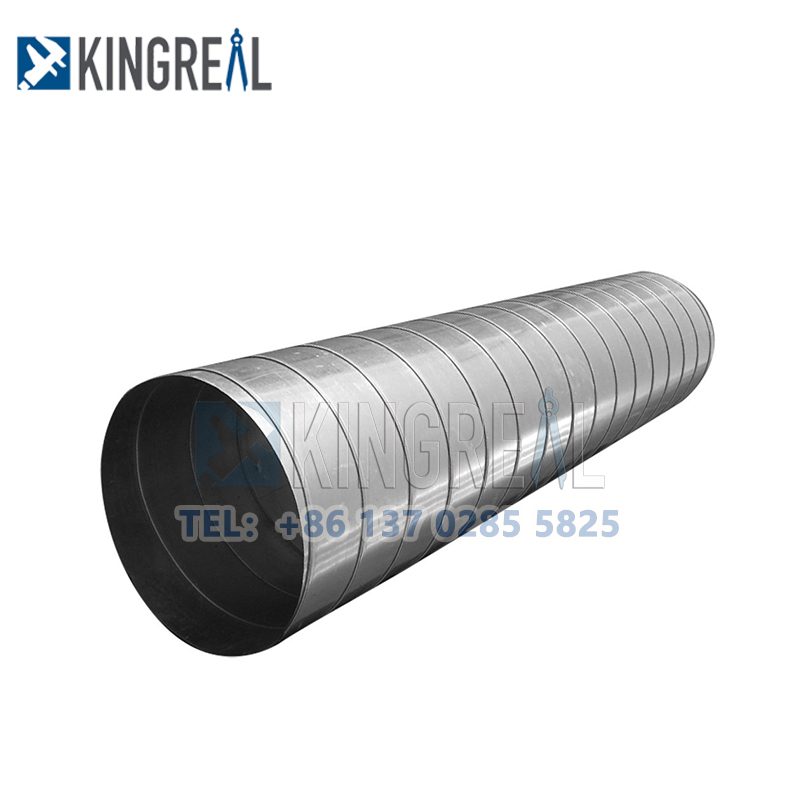

HVAC Spiral Duct Making Machine is an important equipment for producing spiral duct in heating, ventilation and air conditioning (HVAC) system. With the increasing demand for ventilation systems in the construction and industrial fields, spiral duct has been widely promoted due to its excellent performance and low cost. According to the different types of finished products, KINGREAL CEILING MACHINERY can provide customers with round spiral duct machine and rectangular duct making machine.

Spiral duct has the following significant characteristics:

Low wind resistance: The design of spiral duct makes the air flow less resistant, thereby improving the working efficiency of the ventilation system.

High efficiency: Due to the low wind resistance, spiral duct can achieve higher air volume delivery and is suitable for the application of large duct projects.

Good rigidity: The structure of spiral duct makes it have good rigidity, can resist external pressure and maintain stable shape.

Easy installation: Compared with traditional rectangular duct, spiral duct is easier to install, saving installation time and labor costs.

These advantages make spiral duct more important in the ventilation and air conditioning systems of modern buildings.

Application Fields of Spiral Duct Forming Machines

Spiral duct forming machines are widely used in many industries, mainly including the following fields:

1. Construction industry

In the construction industry, good wind resistance performance is an important factor in ensuring indoor air quality. The spiral ducts produced by hvac spiral duct making machines can effectively protect materials from dust and chemical erosion, ensuring the normal operation of the ventilation system.

2. Industrial construction industry

Industrial buildings usually require high strength and good sealing performance to ensure the safety of pipes and pipelines. The structure of the spiral duct can provide the necessary strength, and its good sealing can prevent air leakage and improve the overall efficiency of the system.

3. Gas pipeline industry

In the gas pipeline industry, the good sealing performance of the spiral duct can effectively protect the gas pipeline from water and other external factors, ensuring the safe transportation of gas.

4. Chemical industry

The chemical industry requires strict sealing performance to seal various chemicals. The design of the spiral duct can meet this requirement and prevent the leakage of harmful substances.

5. Water treatment industry

In the water treatment industry, spiral ducts are used to seal water treatment equipment in the pipeline system, such as filters and pump cylinders. High sealing performance ensures the efficiency and safety of the water treatment process.

6. Agricultural machinery field

Agricultural machinery requires high sealing performance during use to protect the equipment from water erosion. The application of spiral ducts can effectively extend the service life of the equipment.

Advantages of Spiral Duct Forming Machines

Compared with other duct manufacturing equipment, hvac spiral duct making machines have many unique advantages:

1. Excellent sealing performance

The design of spiral ducts makes it significantly better than traditional rectangular ducts in terms of sealing performance. KINGREAL CEILING MACHINERY spiral duct forming machines use precise forming processes to ensure that every seam and joint can effectively prevent air leakage. This excellent sealing performance not only improves the overall efficiency of the ventilation system, but also ensures the stability of air quality. Especially in environments where temperature and humidity need to be controlled, good sealing can reduce energy loss and reduce operating costs, which is essential for maintaining indoor comfort.

In many construction projects, spiral ducts produced by hvac spiral duct making machines are widely used in ventilation systems of commercial and industrial buildings. Due to their excellent sealing performance, these ducts can effectively resist the intrusion of external pollutants and ensure the health and safety of the indoor environment.

2. Fast processing speed

In modern manufacturing, production efficiency is one of the keys to corporate competitiveness. KINGREAL CEILING MACHINERY spiral duct forming machines have fast processing speeds, which can significantly improve production efficiency. The equipment has been optimized to complete the production of ducts of different diameters in a short time, greatly adapting to changes in market demand.

The high efficiency of the spiral duct forming machine enables manufacturers to complete large orders in a shorter time. This not only shortens the delivery cycle, but also improves customer satisfaction, making the hvac spiral duct making machine stand out in the highly competitive market.

3. Ability to handle a variety of raw materials

Another significant advantage of KINGREAL CEILING MACHINERY spiral duct forming machines is their ability to handle a variety of metal raw materials, including galvanized sheets, aluminum sheets, etc. This flexibility allows manufacturers to choose the most suitable materials according to the specific needs of customers, thereby reducing production costs.

In different application scenarios, customers may have different requirements for the material of the duct. For example, some industrial environments may require stronger corrosion resistance, while others may focus more on cost-effectiveness. The diversified processing capabilities of the hvac spiral duct making machine enable manufacturers to easily meet these different needs and enhance market competitiveness.

4. Controllable cutting length

The cutting system of the KINGREAL CEILING MACHINERY spiral duct forming machine is highly flexible, and the cutting length can be precisely controlled according to customer needs. This flexibility ensures that the cutting effect of each duct can reach the best state and avoids material waste caused by improper cutting.

In addition, the hvac spiral duct making machine adopts a noiseless cold shear cutting method, which greatly reduces the noise during the production process and improves the working environment of the factory. This advantage not only improves the working comfort of employees, but also meets modern environmental protection standards.

5. Strong adaptability

With the continuous changes in market demand, the adaptability of spiral duct forming machines is particularly important. KINGREAL CEILING MACHINERY spiral duct forming machine can be adjusted according to different production needs and adapt to the production of ducts of various specifications. This high degree of flexibility and adaptability enables the hvac spiral duct making machine to meet diverse market needs and improve the flexibility of the production line.

In the construction industry, the design and needs of the project often vary. The adaptability of the hvac spiral duct making machine enables manufacturers to respond quickly to customer needs and provide the best solution in terms of duct diameter, length or material.

Future Development Trends of Spiral Duct Forming Machine

With the increasing awareness of environmental protection and the continuous development of the construction industry, the technology of hvac spiral duct making machines is also constantly improving. The future spiral duct forming machines will pay more attention to the following aspects:

1

Automation and intelligence

With the development of automation technology, the future KINGREAL CEILING MACHINERY hvac spiral duct making machines will be more intelligent and able to achieve a higher degree of automation. This not only improves production efficiency, but also reduces manual intervention and reduces the error rate.

2

Energy-saving and environmentally friendly design

Future spiral duct forming machine will pay more attention to energy saving and environmental protection, using more efficient motors and energy-saving technologies to reduce energy consumption and emissions. At the same time, waste management and recycling in the production process will also become an important focus.

3

Improve processing accuracy

With the advancement of technology, the processing accuracy of hvac spiral duct making machines will continue to improve. This will make the produced spiral ducts more in line with customers' strict requirements in terms of size and quality.

Get the latest price? We'll respond as soon as possible(within 12 hours)