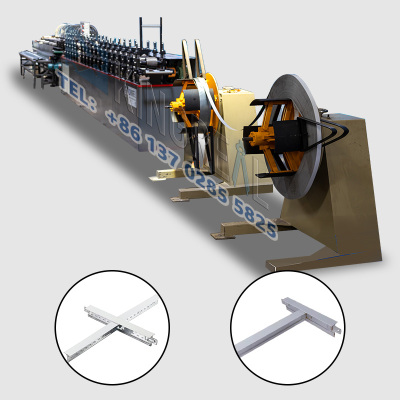

Suspended Ceiling Wall Angle Machine

This suspended ceiling wall angle machine is custom-made to your specific specifications, offering high flexibility and adaptability to perfectly meet your project needs. Suspended ceiling wall angle machines, specialized equipment for producing suspended ceiling wall angles, are essential components in the construction industry. They produce high-quality, precise l angle profiles from sheet metal (typically steel), ensuring the overall quality of the metal ceiling system.

- KINGREAL CEILING MACHINERY

Details

Video About Suspended Ceiling Wall Angle Machine

Description of Suspended Ceiling Wall Angle Machine

This suspended ceiling wall angle machine is custom-made to your specific specifications, offering high flexibility and adaptability to perfectly meet your project needs. The l angle profile roll forming machine is equipped with comprehensive safety features to ensure operator safety during operation. Suspended ceiling wall angle machines, specialized equipment for producing suspended ceiling wall angles, are essential components in the construction industry. They produce high-quality, precise l angle profiles from sheet metal (typically steel), ensuring the overall quality of the metal ceiling system.

KINGREAL CEILING MACHINERY offers complete metal ceiling system solutions. This system consists of suspended ceiling wall angles produced by the l angle profile roll forming machine, main t and cross t produced by the ceiling t bar machine, and lay in ceiling panels produced by the lay in metal ceiling tile production line, creating a complete and efficient metal ceiling solution. As a key component of this system, the suspended ceiling wall angle machine manufactures the profiles that connect the ceiling and walls, ensuring the stability and aesthetics of the overall structure.

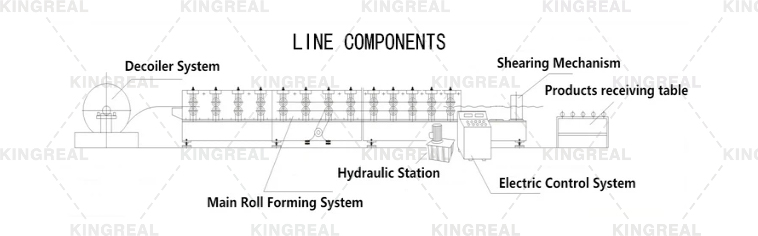

Workflow of L Angle Profile Roll Forming Machine

Decoiler- Roll Forming Machine- Cutting Station- Output Table

Parameters of Suspended Ceiling Wall Angle Machine

| Processing Material | GI coils |

Input Width | Customized |

| Formed Width | As needing |

| Material Thickness | 0.3- 0.4mm |

| Frame Style | 400mm H Beam Welded |

| Material of Rollers | 45# steel, with heat treatment and hard chromed |

| Diameter of Shaft | 50mm |

| Roller Driven | Chain Transmission |

| Cutting Model | Hydraulic Profile Cutting |

| Length Measurement | Encoder |

| Control Style | PLC |

| Operation Model | Button+Touch Screen |

| Total Power | 5.5+4KW; customized |

| Voltage | 380V, 50Hz, 3 phrases; or at buyer’s request |

Parameters of Finished Product

| Name | Dimension(mm) | Length(mm) | Thickness(mm) |

Main t | 32*24 | 3600/3660 | 0.23/0.26/0.28/0.30/0.35/0.40 |

| 38*24 | 3600/3660 | 0.23/0.26/0.28/0.30/0.35/0.40 | |

| Cross t | 26*24 | 1200/1220 | 0.23/0.26/0.28/0.30/0.35/0.40 |

| Cross t | 26*24 | 600/610 | 0.23/0.26/0.28/0.30/0.35/0.40 |

| Wall angle | 22*22 | 3000/3050 | 0.23/0.26/0.28/0.30/0.35/0.40 |

Main Components of L Angle Profile Roll Forming Machine

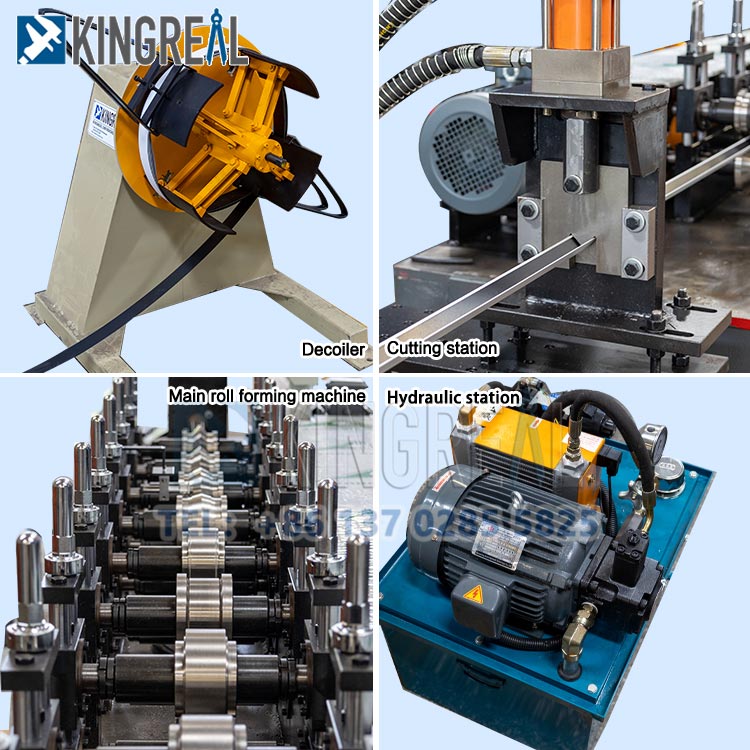

-Decoiler for l angle profile roll forming machine: After the coil is loaded, the decoiler quickly unwinds the metal coil, ensuring smooth subsequent forming processes.

-Roll forming machine for suspended ceiling wall angle machine: The roll forming machine's rollers roll the metal coil into the desired angle shape, ensuring profile forming accuracy.

-Cutting station for l angle profile roll forming machine: Based on the finished length set by the user on the PLC control panel, an encoder detects the length before the cutting station performs precision cutting, ensuring the consistency of each finished product.

Why Choose a KINGREAL CEILING MACHINERY Suspended Ceiling Wall Angle Machine?

1. KINGREAL CEILING MACHINERY Provides Complete Ceiling Systems

KINGREAL CEILING MACHINERY offers comprehensive metal ceiling system solutions. KINGREAL CEILING MACHINERY l angle profile roll forming machines create suspended ceiling wall angles, a crucial component of metal ceiling support, connecting the ceiling to the wall corners. KINGREAL CEILING MACHINERY also provides other essential equipment, such as ceiling t bar machines and lay in metal ceiling tile production lines, to ensure that every customer's needs are met during installation. KINGREAL CEILING MACHINERY lay in metal ceiling tile production line can produce metal ceiling panels of various sizes, such as 30x30cm, 60x60cm, and 120x60cm, according to customer needs. The ceiling t bar machine can produce various types and sizes of main t and cross t, including flat ceiling t grid, FUT ceiling t grid, center black line ceiling t grid, and silhouette groove ceiling t grid meeting the diverse needs of various projects.

2. KINGREAL CEILING MACHINERY Provides Comprehensive Services

In the initial phase, KINGREAL CEILING MACHINERY will accompany customers on a factory tour, provide professional l angle profile roll forming machine operation explanations, and develop a customized suspended ceiling wall angle machine manufacturing plan. In the mid-term, KINGREAL CEILING MACHINERY will rigorously manufacture the l angle profile roll forming machine and provide real-time progress feedback to customers. Upon completion, KINGREAL CEILING MACHINERY will invite customers to its factory for a test run to ensure proper operation. KINGREAL CEILING MACHINERY can also dispatch professionals to the customer's facility to install the suspended ceiling wall angle machine, ensuring a smooth installation process.

In the final phase, KINGREAL CEILING MACHINERY will continuously monitor customer machine usage, provide regular maintenance and troubleshooting services, and ensure that the customer's l angle profile roll forming machine is always in optimal condition.

3. KINGREAL CEILING MACHINERY Provides High-Quality L Angle Profile Roll Forming Machines

As a manufacturer of suspended ceiling wall angle machines with over 20 years of experience, KINGREAL CEILING MACHINERY guarantees high-quality machines. Some rollers in KINGREAL CEILING MACHINERY l angle profile roll forming machine are made of CR12 die steel, with an average hardness of HRC55, ensuring durability and stability of the finished product. Furthermore, the blades in the cutting station are made of high-hardness material, ensuring precise cutting results.

During the suspended ceiling wall angle machine manufacturing process, KINGREAL CEILING MACHINERY professional team rigorously inspects all l angle profile roll forming machine components to ensure that each machine meets high standards. After the suspended ceiling wall angle machine is installed, KINGREAL CEILING MACHINERY staff conduct multiple test runs, setting different production parameters to verify the l angle profile roll forming machine's consistent production accuracy under various conditions.

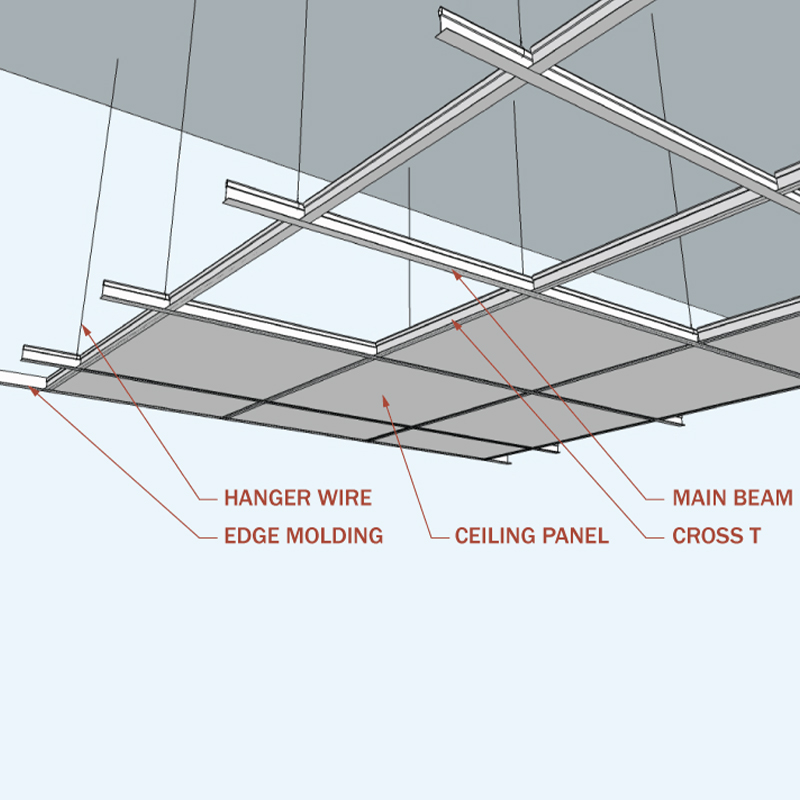

Lay in Ceiling System Installation Process

The installation of ceiling t bar and l angle profile is relatively simple, but requires specific steps to ensure the stability and aesthetics of the final metal ceiling system.

1) Securing the suspended ceiling wall angle: First, secure the l angle profile at the designated ceiling height and ensure it is level.

2) Installing the main t: Above the suspended ceiling wall angle, secure the main t at 1200mm intervals. This step is crucial for ensuring the overall support of the ceiling.

3) Inserting the cross t: Finally, the long cross t are inserted onto the main t at 600mm intervals to form a complete ceiling frame.

Through this installation process, combined with KINGREAL CEILING MACHINERY l angle profile roll forming machine, ceiling t bar machine, and lay in metal ceiling tile production line, customers can easily construct a lay in metal ceiling system that meets project requirements, improving overall project quality and aesthetics.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)