Metal ceiling tile perforation line for suspended ceiling system

2025-09-09 18:36

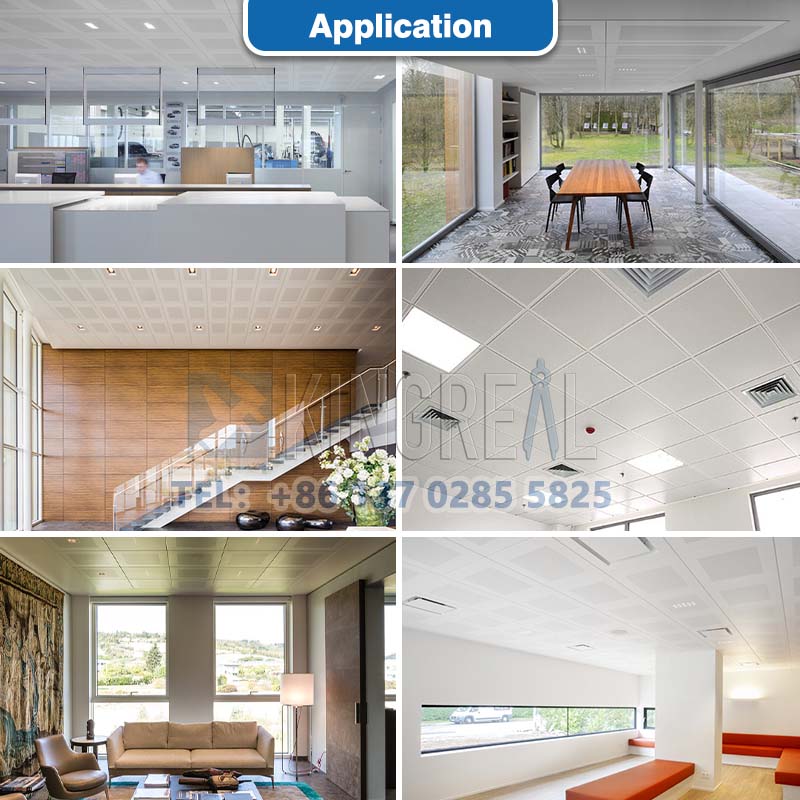

In suspended ceiling systems, perforated ceilings produced by metal ceiling tile perforation lines are decorative elements within homes and a crucial component in enhancing functionality and comfort. They provide flame resistance, moisture resistance, corrosion resistance, stain resistance, and noise reduction in addition to good absorption. With each panel separately detachable for simple installation and upkeep, they are simple to put together and take apart. Furthermore, they offer great heat dissipation and ventilation, producing a transparent and big area that helps to circulate air and makes for a more pleasant indoor environment. Due to their superior performance, perforated ceilings produced by perforated metal ceiling tile machines are the preferred ceiling material for airports, stadiums, schools, banks, hotels, office buildings, shopping malls, libraries, stations, factories, hospitals, and other locations. This article will discuss in detail the operating principles and advantages of metal ceiling tile perforation lines.

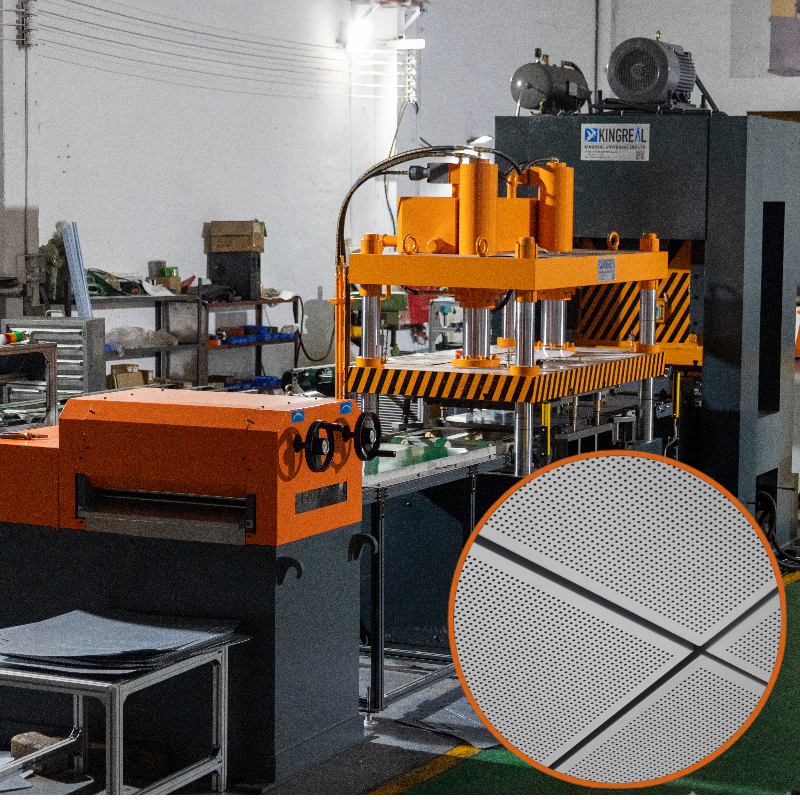

Introduction to Perforated Metal Ceiling Tile Machine

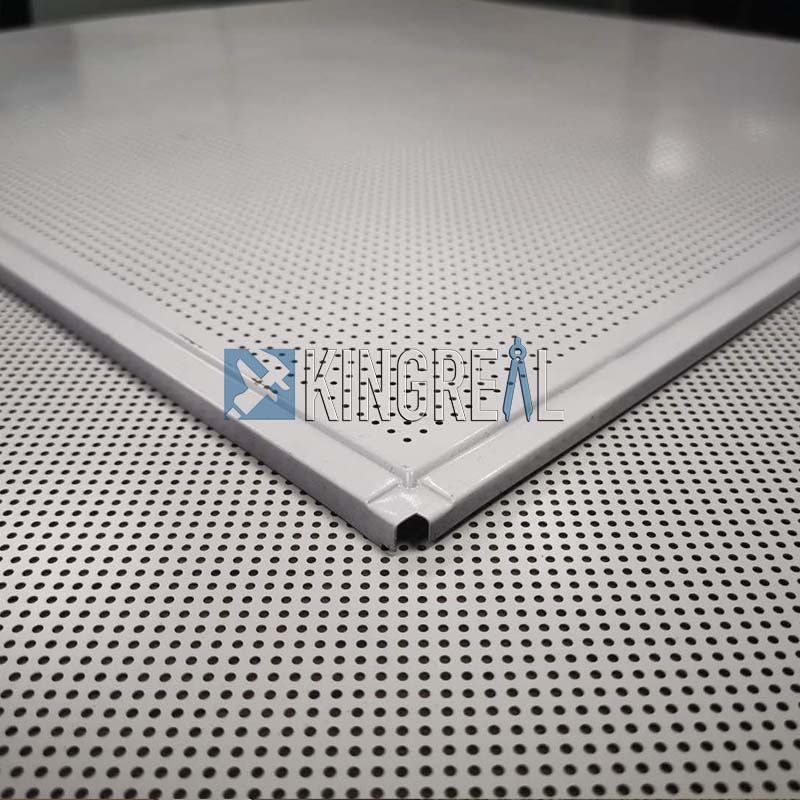

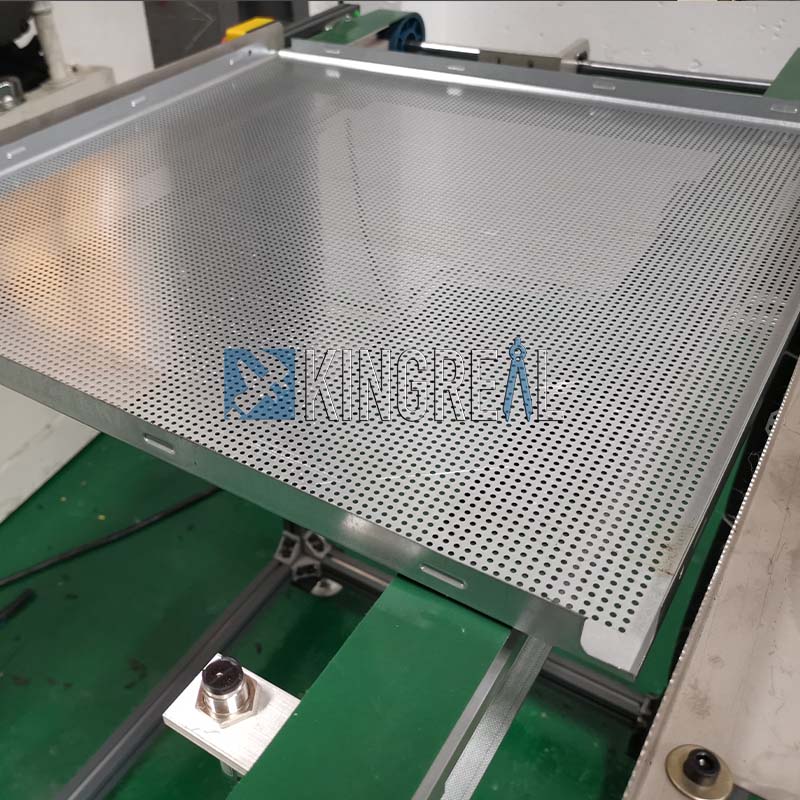

Metal ceiling tile perforation lines are used to process galvanized iron coils, aluminum coils, and roll-coated coils. These perforated metal ceiling tile machines typically process iron coils with thicknesses between 0.4 and 0.5 mm, and aluminum coils with thicknesses between 0.5 and 0.6 mm. Including Lay In ceiling tile (T24, T15), Lay On ceiling tile, Clip In ceiling tile, and Tegular ceiling tile, this metal ceiling tile perforation line can create several perforated ceiling panels. It can also fit panels in several sizes, including 600×600mm, 300×300mm, 300×600mm, 300×1200mm, and 600x1200mm.

During the production process, KINGREAL CEILING MACHINERY can customize punching dies based on customer drawings. Common hole diameters include 1.8mm and 2.5mm. The perforated metal ceiling tile machine can also produce a variety of special hole shapes, including round holes, long round holes, square holes, triangle holes, diamond holes, hexagonal holes, and crossed holes. For more specific production requirements, please provide your drawings to KINGREAL CEILING MACHINERY. KINGREAL CEILING MACHINERY will tailor a customized metal ceiling tile perforation line solution based on your specific needs.

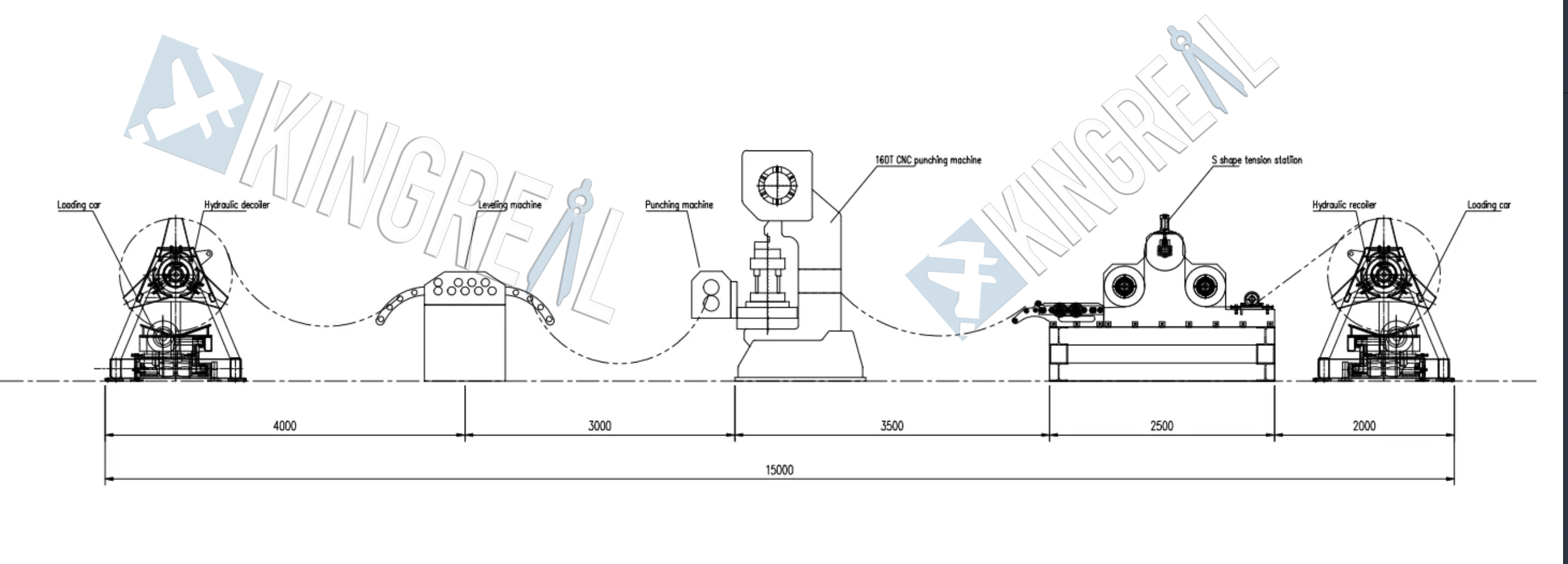

Workflow of Perforated Metal Ceiling Tile Machine

Decoiler-Precision Straightner-Punching Machine-Notching and shearing press-2 nd Precision Straightner-Bending forming press

Advantages of Perforated Ceiling Tiles

1. High Aperture Ratio

Usually between 20% and 70%, the aperture ratio of perforated ceiling tiles lets customization according on particular needs. Apart from improving the ceiling's appearance, this great aperture ratio significantly raises interior light levels. Designers can choose the right hole pattern and diameter depending on the exact use of the space, hence realizing the intended visual impact and usability thanks to this adaptability.

In regions requiring natural light, for instance—corridors and offices—perforated ceilings with a high aperture ratio might improve light transmission to create a bright and open environment. Perforated ceilings enliven the area and help to fight the drabness often connected with flat ceilings. Furthermore reducing reliance on artificial lighting helps to save energy and improve the environment via this design.

2. Excellent Light Transmission

Perforated ceiling panels help to improve inside illumination and maximize light transmission by means of precisely spaced tiny apertures. Good light transmission not just lightens the area but also produces a soft, mild glow, therefore preventing glare from direct sunshine. In business settings like showrooms and shopping malls, this feature is especially crucial. Highly light-transmitting perforated ceiling panels improve the customer experience and highlight product exhibitions.

Customizing punching dies for metal ceiling tile perforation line, KINGREAL CEILING MACHINERY may fulfill the lighting needs of different settings by maximizing light transmission. Highlighting perforated ceiling panels, for instance, can greatly lower direct illumination and improve comfort in calm settings like schools and hospitals. Moreover, ideal lighting distribution can increase work and learning efficiency while enhancing mood.

3. Sound and Heat Insulation

Perforated ceiling panels offer some thermal insulation and successfully mute outside noise, hence increasing interior comfort. In offices, schools, hospitals, and other settings, noise management is really important. Perforated ceiling panels, with their unique hole design, effectively absorb sound and reduce echoes, creating a quiet environment.

KINGREAL CEILING MACHINERY provides customers with exactly designed metal punching machine and punching dies that guarantee the consistency of every hole, therefore maximizing sound insulation. Perforated ceiling panels considerably decrease background noise and improve privacy by means of best hole pattern and diameter construction. Their thermal insulation characteristics are also very important. By efficiently isolating the inside from heat, they help to cut air conditioning energy use and maintain a constant indoor temperature, hence improving comfort in living and employment.

Optional for Metal Ceiling Tile Perforation Line

1. Metal sheet cleaning machine for metal ceiling tile perforation line Perforated metal ceiling tile machines are equipped with a metal sheet cleaning machine to clean oil and impurities generated during the production process. Following the creation of perforated ceiling panels of different sorts and sizes, the metal sheet cleaning machines quickly cleans and dries the completed product to guarantee a neat and orderly appearance. Apart from boosting production efficiency, this process gives customers premium goods and helps to lessen the load of later cleaning. The metal sheet cleaning machine typically features dual-sided washing and rapid drying functions, effectively handling ceiling panels of various materials and shapes. This efficient cleaning method allows customers to obtain clean, neat perforated ceilings in a short time, shortening delivery cycles.

|  |

2. Acoustic fleece sticking machine for metal ceiling tile perforation line To enhance the sound insulation of perforated ceilings, KINGREAL CEILING MACHINERY can also equip perforated metal ceiling tile machines with acoustic fleece sticking machine. This machine customizes rolls of material to accommodate corresponding ceiling dimensions, such as 600×600mm, based on customer needs. The acoustic fleece sticking machine applies the material during the perforated ceiling production process, further enhancing its sound insulation performance. |  |

Perforated Ceiling Installation

1. Preparation Before construction, the construction area must be surveyed and measured to confirm the size and shape of the ceiling. A detailed construction plan must be developed, and the necessary materials and equipment must be prepared.

2. Frame Installation Perforated aluminum veneer ceilings require a sturdy frame for support. The frame layout and shape must be determined according to the design drawings, ensuring stability and accuracy.

3. Installing the Perforated Aluminum Veneer Before installation, the aluminum veneer must be drilled or cut to meet design requirements. Use specialized fasteners to secure the aluminum veneer to the frame, paying attention to the horizontal and vertical alignment of the panels to ensure overall flatness.

4. Connecting and Addressing Gaps Gaps created during installation must be addressed with special aluminum strips and connectors to maintain a consistent appearance and enhance the stability and durability of the ceiling.

5. Surface Treatment and Decoration The surface of perforated aluminum veneer requires special treatment, such as painting or spraying, to enhance its visual appeal and aesthetics. Select appropriate materials and processes to ensure durability and easy cleanability.

6. Decoration and Lighting Decorative strips or lighting can be incorporated into the design to enhance the sense of depth and artistic quality of the space. During installation, ensure stability and electrical safety.

7. Cleaning and Maintenance After installation, remove debris from the site and regularly inspect and maintain the condition of the ceiling to extend its lifespan. Regular cleaning and maintenance are essential. |  |

Get the latest price? We'll respond as soon as possible(within 12 hours)