Baffle Ceiling Machine in Turkey

Baffle Ceiling Machine is one of KINGREAL CEILING MACHINERY featured machines. So far, it has worked closely with customers from Italy, Russia, the United Kingdom, Greece and other countries. This month, KINGREAL CEILING MACHINERY engineers went to the Turkish customer's factory to install the baffle ceiling machine and conduct machine operation training. In this article, KINGREAL CEILING MACHINERY will share with you the detailed after-sales service provided by KINGREAL CEILING MACHINERY to this Turkish customer. If you are interested in KINGREAL CEILING MACHINERY baffle ceiling making machine, please come to consult us. We can not only provide high-quality baffle ceiling machines but also a series of after-sales services that are widely praised by customers! |  |

Brief Introduction to Baffle Ceiling Machine

KINGREAL CEILING MACHINERY baffle ceiling making machine is a highly flexible machine with a roll forming machine roller group that can automatically adjust the width to produce baffle ceilings of different sizes. Usually, KINGREAL CEILING MACHINERY baffle ceiling machine is used to produce baffle ceilings with a width of 25-100mm and a height of 75-300mm, with a production speed of 30m/min. KINGREAL CEILING MACHINERY baffle ceiling making machine can produce various types of finished products such as U-shaped baffle ceiling, V-shaped baffle ceiling, perforated baffle ceiling, etc. And it can also provide customers with baffle ceiling carrier machine to give customers a complete baffle ceiling solution. The baffle ceilings produced by KINGREAL CEILING MACHINERY baffle ceiling making machine are widely loved by people because of their strong sense of fashion and easy installation. |  |

Baffle Ceiling Making Machine Installation in Turkey

1. Turkish customer background

This Turkish customer comes from the construction industry and has clear requirements for the size and type of baffle ceilings. Therefore, after KINGREAL CEILING MACHINERY engineers fully communicated with the Turkish customer and deeply understood his information about the parts of the baffle ceiling making machine, the metal materials to be processed, the metal thickness, the production scale, etc., they combined the Turkish customer's drawings to give the final baffle ceiling making machine manufacturing solution.

After several months of manufacturing, the baffle ceiling machine was completed and successfully sent to the Turkish customer's factory after being tested by the KINGREAL CEILING MACHINERY team.

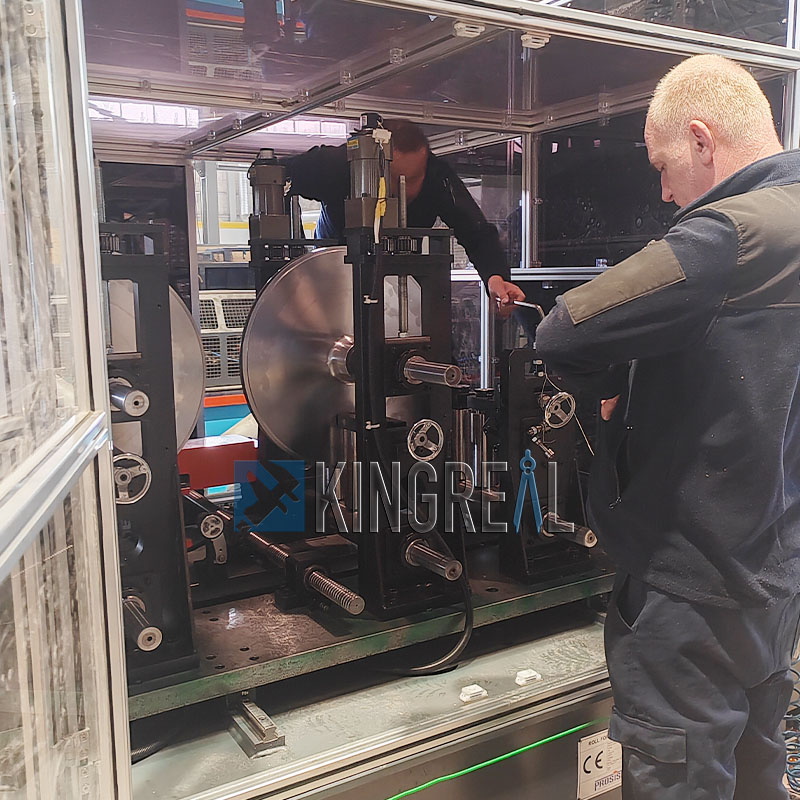

2. Installation of baffle ceiling machine in Turkey After estimating the time for the baffle ceiling making machine to arrive at the Turkish customer's factory, KINGREAL CEILING MACHINERY engineers began to prepare for the installation of the baffle ceiling machin abroad. KINGREAL CEILING MACHINERY engineers and Turkish workers unpacked the various parts of the baffle ceiling making machine and first checked the external state of the parts to confirm whether the machine was in good condition. It is worth mentioning that this Turkish customer paid special attention to the safety of workers during the production process, so KINGREAL CEILING MACHINERY engineers equipped the baffle ceiling machine with a protective shield. When checking the status of the parts, KINGREAL CEILING MACHINERY engineers also focused on the appearance of the protective shield to ensure that the various parts of the baffle ceiling machine remained in good condition after long-distance transportation. |  |

Then KINGREAL CEILING MACHINERY engineers installed the parts of the baffle ceiling machine, including the decoiler, precision leveler, roll forming machine, cutting station, etc., into a complete baffle ceiling production line. And carefully adjusted the roller set of the roll forming machine. The next step is to put the metal coil into the baffle ceiling machine and start to test the working state of the baffle ceiling making machine. This baffle ceiling machine has a high degree of automation. After adjusting the parameters, the baffle ceiling making machine will run automatically. So after the KINGREAL CEILING MACHINERY engineers entered the parameters on the control panel, they watched the operation of the baffle ceiling machine with the workers. From the metal coil entering the decoiler to the precise cutting of the baffle ceiling by the cutting station, KINGREAL CEILING MACHINERY engineers confirmed that the preliminary installation of this baffle ceiling machine has been completed. |  |

Next, they will measure the quality of the baffle ceiling production line, including whether the height and width meet the customer's production requirements, and whether there are burrs on the surface. Since this baffle ceiling making machine has been tested in the KINGREAL CEILING MACHINERY factory, KINGREAL CEILING MACHINERY engineers only need to fine-tune the parameters of the baffle ceiling making machine before the machine can be used smoothly in the Turkish customer's factory. The Turkish customer conducted a comprehensive inspection of the finished products produced by the baffle ceiling machine and praised the quality of the KINGREAL CEILING MACHINERY baffle ceiling machine, saying that the speed of this baffle ceiling production line met his requirements and the precision of the finished products produced was consistent with his expected results. |  |

| 3. Baffle ceiling production line operation training After confirming that the baffle ceiling machine installation was completed and the machine could run stably, KINGREAL CEILING MACHINERY engineers conducted detailed machine operation training for the Turkish workers present. Including how to turn on and off the baffle ceiling production line, how to adjust the parameters on the control panel, etc., and once again emphasized that a baffle ceiling production line can produce finished products of various sizes. You only need to enter the required finished product size parameters on the control panel, and the roller of the roll forming machine will automatically adjust the width and narrowness to achieve the production of finished products of various sizes. |  |

The whole process is automated and does not require excessive human intervention. KINGREAL CEILING MACHINERY engineers first demonstrated the operation of the baffle ceiling production line in person, and then let the Turkish workers operate it. During their operation, KINGREAL CEILING MACHINERY engineers pointed out some of their incorrect operating methods in time. After confirming that the Turkish workers can operate the baffle ceiling making machine independently, the trip ended successfully. |  |

Customer Feedback

This Turkish customer was very satisfied with the after-sales service of the KINGREAL CEILING MACHINERY engineering team, and also gave a very high evaluation of the KINGREAL CEILING MACHINERY baffle ceiling machine. He also said that if the production scale is expanded in the future, there will be a demand for baffle ceiling machines and he will come to KINGREAL CEILING MACHINERY again. KINGREAL CEILING MACHINERY thanks the Turkish customers for their favorable comments on the baffle ceiling making machines and after-sales services provided by KINGREAL CEILING MACHINERY. In the future, KINGREAL CEILING MACHINERY will continue to work hard to continuously improve the research and development and manufacturing of baffle ceiling making machines and continue to provide customers with detailed services! |  |

Get the latest price? We'll respond as soon as possible(within 12 hours)