Wall Siding Panel Making Machine for Construction

2025-10-26 17:00

Wall siding panel making machine, also known as cladding wall panel machine, is indispensable equipment in modern construction projects. These wall siding panel making machines are capable of producing a variety of metal wall panels, including corrugated sheets, trapezoidal panels, and interlocking designs, and are widely used in exterior wall finishes for various buildings. As the construction industry's demands for aesthetics and functionality increase, market demand for cladding wall panel machines is growing. KINGREAL CEILING MACHINERY wall siding panel making machines, with their superior performance and versatility, have become the preferred equipment for numerous construction projects.

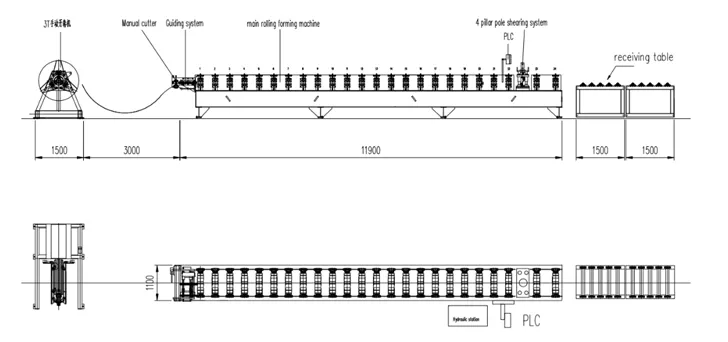

1/Workflow of Cladding Wall Panel Machine

Decoiler--Roll Forming Machine--Cutting Station--Output Table

2/ Advantages of Wall Siding Panel Making Machine

1. Compatible with Various Materials

Wall siding panel making machines are compatible with a wide range of metal materials. Whether galvanized steel, aluminum, pre-painted steel, or stainless steel, these materials can be processed using these cladding wall panel machines, allowing them to meet diverse project requirements. Customers can select the appropriate material based on their specific architectural design and functional requirements, ensuring the performance and aesthetics of the final product.

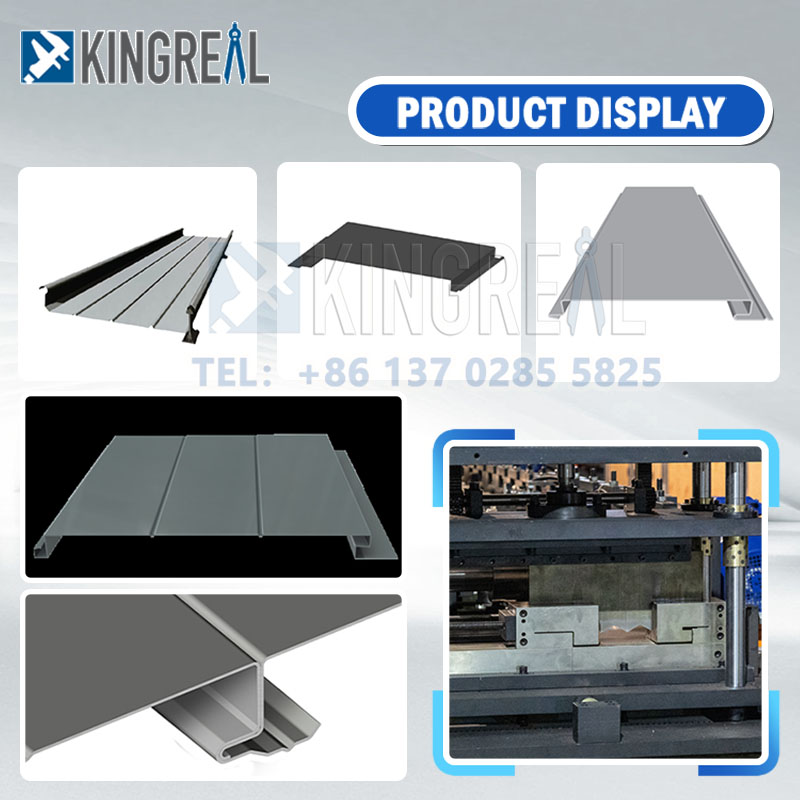

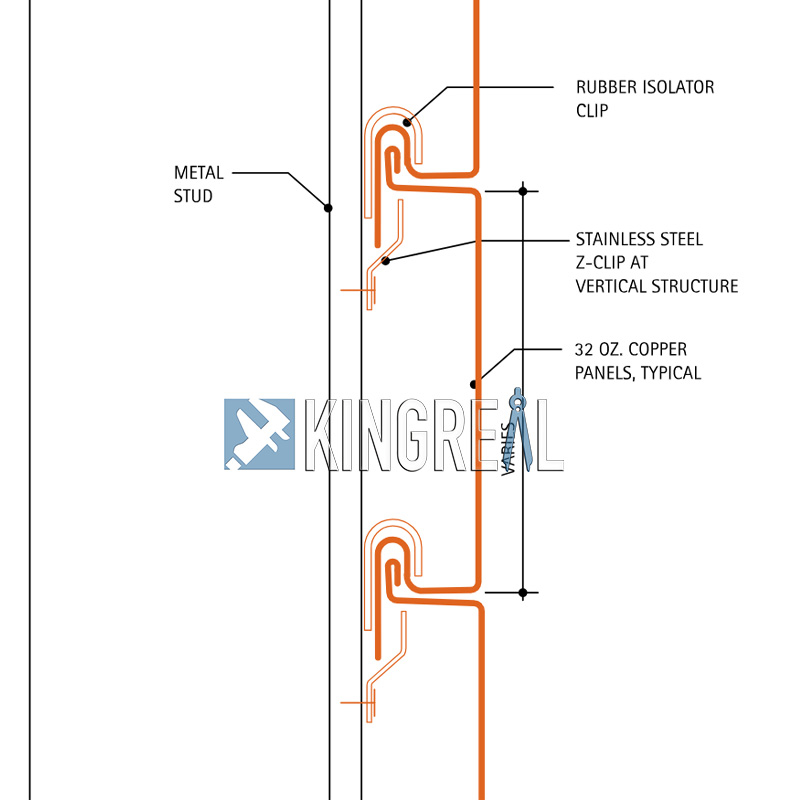

2. Capable of Producing Various Wall Panel Types

KINGREAL CEILING MACHINERY wall siding panel making machines are capable of producing both concealed and exposed fastener panels. Customers can select the appropriate cladding wall panel machine to meet their specific needs, producing the appropriate wall panel type, enhancing the aesthetics and practicality of their buildings.

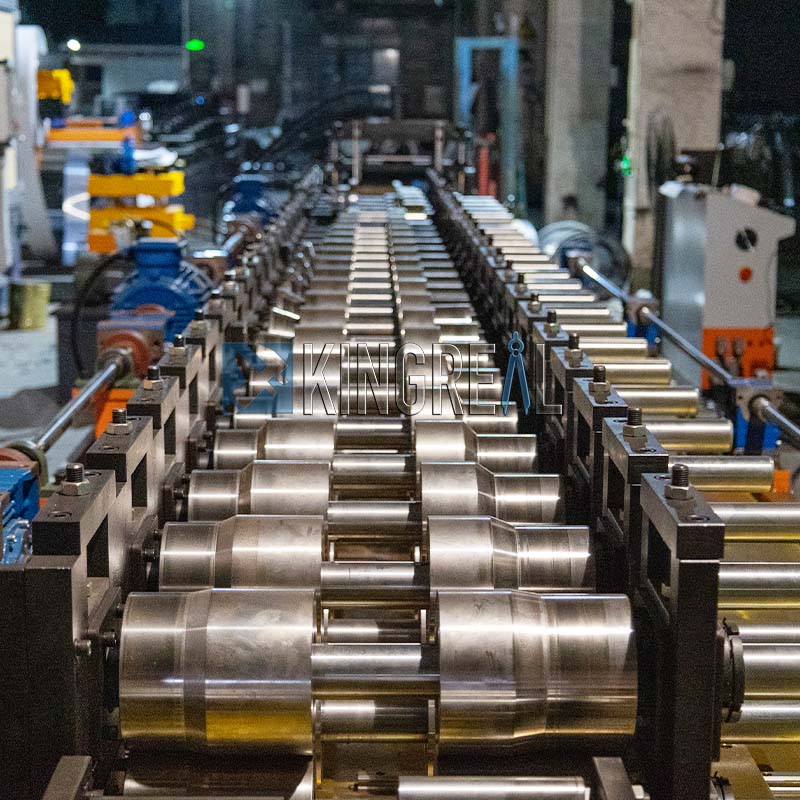

3. High Precision and Tight Tolerances

The wall siding panel making machines are equipped with durable forming rollers and cutting blades, ensuring precise forming and cutting capabilities. This high-precision production process ensures that each wall panel maintains a consistent size and shape, ensuring seamless installation and a professional appearance. This not only improves construction efficiency but also significantly reduces waste caused by dimensional discrepancies.

4. Production in Multiple Specifications and Sizes

The forming section of the cladding wall panel machine can automatically adjust its width by adjusting the PLC control panel, producing finished products of varying sizes. Customers can flexibly select the wall panel specifications and sizes required, providing significant convenience for a variety of construction projects.

5. High Production Speed

KINGREAL CEILING MACHINERY wall siding panel making machines operate at a speed of 40 m/min, far exceeding the production speed of commonly available machines on the market. This high-efficiency production capacity enables contractors to complete more projects in a shorter time-frame, improving overall work efficiency.

3/ Features of Cladding Wall Panel Machine

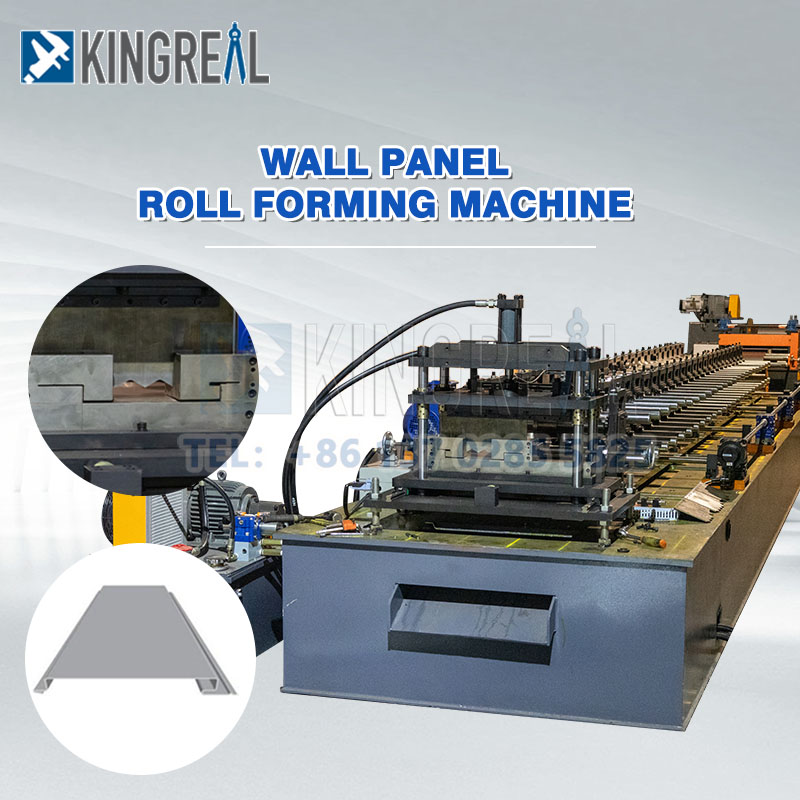

1.Forming rollers for cladding wall panel machine

The forming rollers of wall siding panel making machines are one of their core components. They are made of Cr12 (D3) steel, an alloy steel with high carbon and chromium content, highly valued for its excellent wear resistance, toughness, and strength. The physical properties of Cr12 steel make it an ideal material for forming rollers, capable of withstanding high workloads without wear. Over extended periods of operation, the forming rollers must maintain stable performance to ensure consistent quality and precision of the wall panels produced.

The wear resistance of Cr12 steel ensures a long service life for the forming rollers in large-scale production, reducing the need for replacement due to wear. This not only reduces production costs but also improves overall efficiency. Since cladding wall panel machines are typically used for mass production, using high-quality roller material is crucial for a smooth production process. Furthermore, the toughness of Cr12 steel prevents the rollers from breaking under high temperatures or high pressures, further enhancing the safety and reliability of the wall siding panel making machine.

2.Gearbox drive for cladding wall panel machine

A gearbox drive is a standard feature of wall siding panel making machines, responsible for transmitting the motor's power to the forming rollers. Cladding wall panel machines equipped with a gearbox drive system maintain exceptional precision and stability at high speeds. This system design not only improves production efficiency but also effectively reduces maintenance costs, making the equipment more economical to operate.

The gearbox is designed to withstand high levels of wear, meaning that over long periods of production, the wall siding panel making machine's performance will not be significantly affected by frequent use. Compared to other drive systems, the gearbox drive is more stable under high loads, effectively reducing the chance of failure. This allows manufacturers to ensure continuous operation and efficient output while producing high-quality cladding wall panels.

In addition to improving efficiency, the gearbox drive also provides a positive impact on operational flexibility. Operators can easily adjust the gear ratio to achieve different production speeds based on production needs. This flexibility allows the wall siding panel making machine to better adapt to various project requirements and meet customer requirements for different wallboard specifications.

3.Archway roller standing for cladding wall panel machine

The positioning system of a wall siding panel making machine is crucial to ensuring the precision and quality of the final product. The Arch Roller Column design ensures the metal forming rollers maintain a stable position during operation. Using stepped nuts, operators can quickly, easily, and safely adjust roller settings. This design not only improves accuracy during the forming process, preventing product defects caused by misalignment, but also significantly increases production efficiency.

The precise positioning system ensures consistent pressure and position of the forming rollers throughout the production process, resulting in uniform forming results for each wallboard. This consistency not only improves product appearance quality but also reduces subsequent processing issues and rework. For mass-produced wallboards, ensuring precision for every piece is crucial and directly impacts customer satisfaction and product competitiveness.

The Arch Roller Column design is designed with safety and convenience in mind, allowing operators to avoid potential safety hazards during adjustments. A simple mechanism allows operators to quickly adjust the rollers, reducing cladding wall panel machine downtime and ensuring a smooth production process.

4.Punching station for cladding wall panel machine(Optional)

For customers requiring punching, KINGREAL CEILING MACHINERY can equip wall siding panel making machine with a punching station to further enhance its functionality. The punching station allows precise holes to be punched into the metal coil during the wallboard forming process to meet specific design requirements. This optional feature provides customers with great flexibility, allowing them to customize the punching die to meet specific project requirements.

Punching accuracy is crucial to the quality of the final product. By incorporating a punching step into the forming process, the wallboard forming machine can produce more complex and diverse wallboards to meet diverse architectural styles and functional requirements. This capability extends the cladding wall panel machine beyond traditional wallboard production and expands its application to a wider range of scenarios, providing customers with more options.

Furthermore, the punching station's integrated design significantly reduces production time and the need for subsequent processing. By completing multiple steps in a single forming process, customers can not only reduce production costs but also improve overall efficiency. This integrated design concept makes KINGREAL CEILING MACHINERY wall siding panel making machines more competitive in the market.

4/ Introduction to Cladding Wall Panel

Metal wall panels produced by KINGREAL CEILING MACHINERY wall siding panel making machines are increasingly popular due to their superior durability, aesthetics, and improved building energy efficiency. These wall siding panels are not only suitable for exterior wall decoration, but also effectively resist the elements, extending the lifespan of the building.

Whether you're a DIY enthusiast or a contractor, the wide range of applications for wall siding panels makes them an ideal choice for enhancing the appearance and performance of your building.

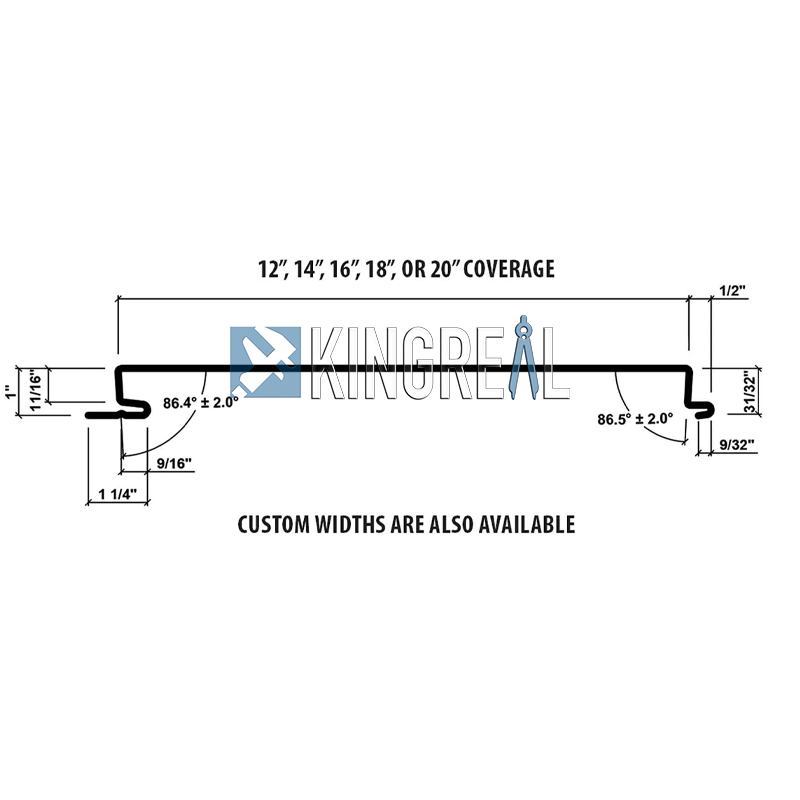

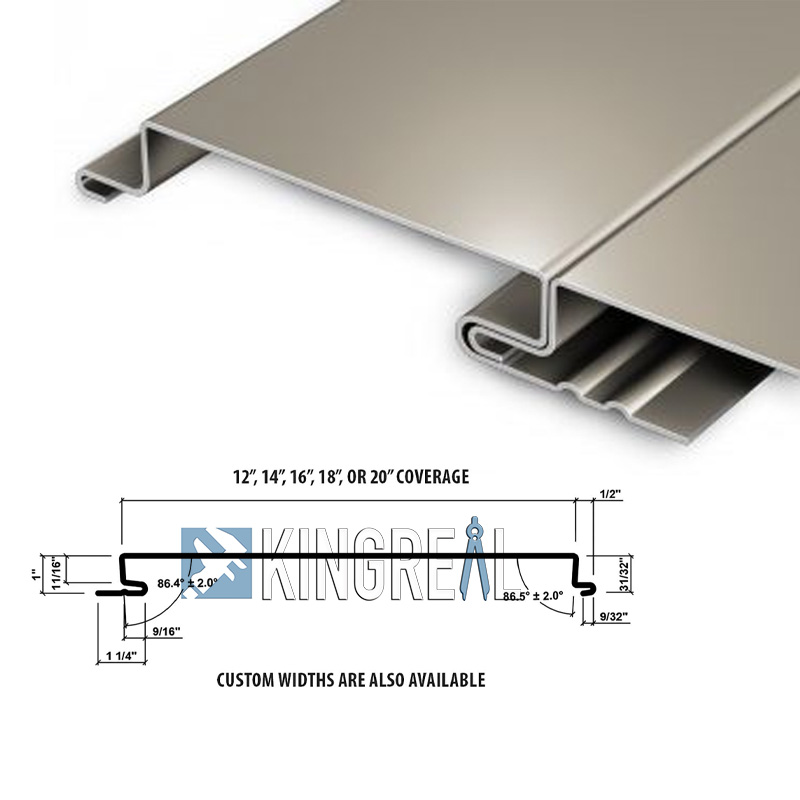

Drawing about cladding wall panel:

Get the latest price? We'll respond as soon as possible(within 12 hours)