What is the purpose of perforated metal sheet?

2024-11-25 17:15

Video About Sheet Metal Perforating Machine

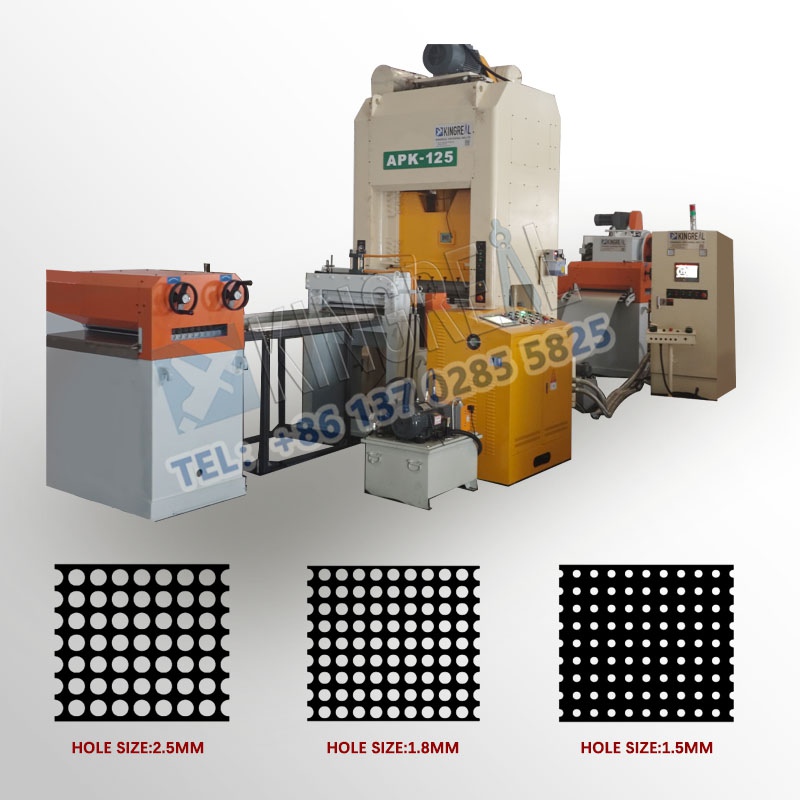

Introduction to Sheet Metal Perforating Machine

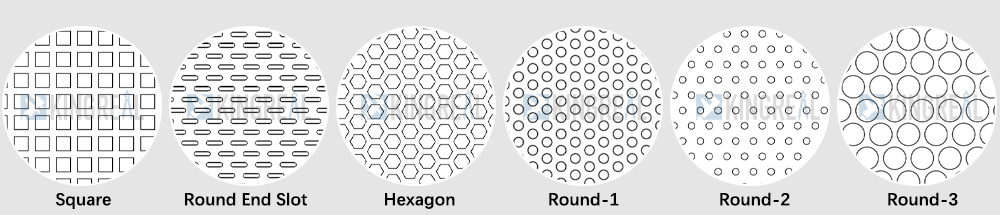

Perforated metal sheet is a metal sheet made of metal materials such as steel or aluminum placed in a metal sheet perforation machine, with multiple holes of different shapes and sizes. The cutting station then accurately cuts according to the customer's preset length. Usually, the sheet metal perforating machine can process metal coils with a thickness of 0.4-1.0mm. The hole shape of the perforated sheet can be circular, rectangular, diamond, hexagonal, etc., and the hole size can be customized as needed. |  |

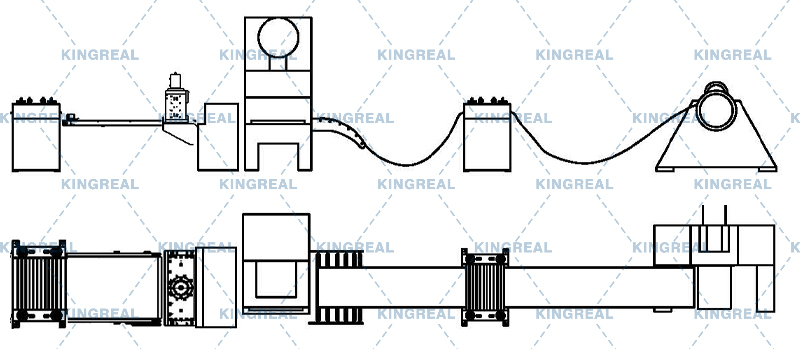

Working Process of Sheet Metal Perforating Machine

Decoiler -- Leveling Machine -- Metal Punching Machine --Cutting station -- Output Table

Two commonly used modern perforation methods

1. Aluminum perforated machine Punching by a perforated sheet making machine is a more common perforation method. The punching method of the machine tool is used to punch holes on the metal surface. The punching process can achieve rapid perforation. And according to the different production needs of customers, KINGREAL CEILING MACHINERY can also configure a variety of components such as recoilers, cutting stations, metal sheet cleaning machines, and feeding trolleys for the perforated sheet making machine. 2. Laser perforation line Laser perforation is the latest development of perforation technology. It is also a more expensive and complex technology with high precision and randomness. |  |

Characteristics of Perforated Sheet Making Machine

1. Porosity

The advantages of metal sheet perforation machines are as follows. The most direct appearance feature of perforated metal plates is porosity. Porosity means that the two spaces separated by the surface are permeable to each other, breaking the inherent boundaries between inside and outside, and creating a more open public space in form.

It can provide the city and users with the required intuitive feeling, and truly achieve the mutual penetration of internal and external spaces. The porosity of perforated metal plates allows the indoor and outdoor spaces to penetrate each other.

Under the illumination of sunlight or light, perforated metal plates will produce rich light and shadow changes. This effect will give the building a unique and flexible visual effect, and different hole types produce different light and shadow effects.

2. Multiple combinations

Perforated steel sheet can be made into different shapes and sizes according to the needs of architects. Different connection combinations are possible, and the combination methods are rich and varied.

3. Reduce sound level

Research shows that perforated steel sheets can help reduce sound levels, and their acoustic properties can help personnel reduce the impact of noise on health.

When the frequency of the incident sound wave is consistent with the resonant frequency of the system, the air in the perforated metal sheets will vibrate and rub violently, The absorption effect is strengthened and an absorption peak is formed, which significantly attenuates the sound energy.

Far away from the resonant frequency, the absorption effect is smaller. If sound-absorbing materials are placed behind the perforated metal sheets to increase the sound resistance, the absorption band of the structure will be broadened.

Metal perforated panels are used in indoor and outdoor decoration of concert halls, theaters, cinemas and other spaces.

Application of Perforated Sheet Making Machine

1. In the field of construction, perforated sheet making machine can be used to decorate the exterior walls, interior walls, ceilings and other parts of buildings, with beautiful, breathable, heat-insulating and other effects. 2. In the field of mechanical manufacturing, metal sheet perforation machine can be used to make filters, screens, condensers and other parts, which can be used for filtering, separation and purification. 3. In the industrial field, metal sheet perforation machine can be used to make oxygen generators, exhaust gas emission equipment, fans and other equipment, which can be used for ventilation, sound insulation and other functions. 4. In other fields, metal sheet perforation machine can also be used to make furniture, artworks, speakers and other products. |  |

Get the latest price? We'll respond as soon as possible(within 12 hours)