Aluminium Strip Perforated Machine

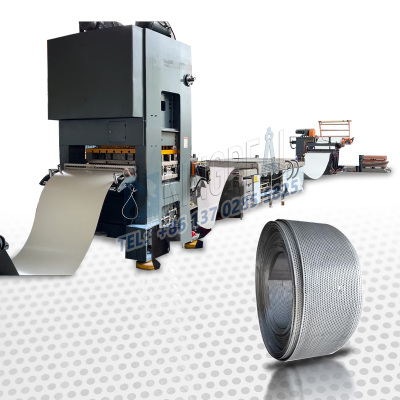

This aluminium strip perforated machine is specifically designed for punching metal materials such as stainless steel and aluminum with widths of several tens of centimeters. It aims to provide customers with efficient production capabilities and customized aluminium strip perforated line manufacturing solutions.

- KINGREAL CEILING MACHINERY

Details

Video About Aluminium Strip Perforated Machine

Definition of Aluminium Strip Perforated Machine

This aluminium strip perforated machine is specifically designed for punching metal materials such as stainless steel and aluminum with widths of several tens of centimeters. It aims to provide customers with efficient production capabilities and customized aluminium strip perforated line manufacturing solutions. And aluminium strip perforated machine is widely used in a variety of industries, including construction, automotive, and electronics. Whether for large-scale production or customized needs, KINGREAL CEILING MACHINERY aluminium strip perforated lines can meet the diverse needs of the industry.

This aluminium strip perforated machine is primarily composed of multiple precision components, including a decoiler, leveling machine, metal punching machine, and cutting station or recoiler. These components work together to produce highly accurate and consistent perforated metal coils or sheets. Leveraging years of experience and rigorous performance and quality inspections, KINGREAL CEILING MACHINERY offers a wide range of advanced, high-precision aluminium strip perforated lines. For more information on various aluminium strip perforated machine manufacturing options, please contact KINGREAL CEILING MACHINERY. |  |

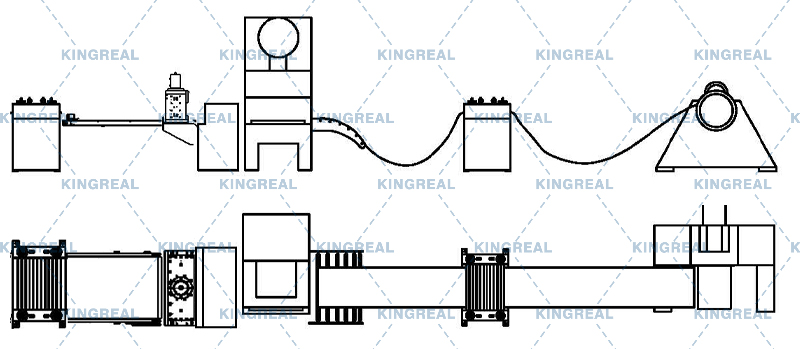

Working Process of Aluminium Strip Perforated Line

Decoiler--Leveling Machine--Metal Punching Machine--Cutting Station/Recoiler

Main Components of Aluminium Strip Perforated Line

Feeding unit for aluminium strip perforated machine

The aluminium strip perforated machine's feeding system consists of a feeding trolley, decoiler, leveling machine. The loading trolley automatically delivers the coil to the decoiler, which unwinds the coil, and the leveling machine flattens the coil surface. This series of operations is precisely executed by a servo control system, ensuring accurate feeding of the aluminium strip perforated line, ensuring that every punched sheet meets customer specifications.

Punching unit for aluminium strip perforated line

KINGREAL CEILING MACHINERY offers a variety of punching dies for its customers' aluminium strip perforated machines, ensuring that every customer achieves perfect punching results. Whether it's a simple circular hole or a complex polygon, KINGREAL CEILING MACHINERY aluminium strip perforated machine can easily handle it, providing the optimal punching solution and ensuring the highest efficiency and quality in KINGREAL CEILING MACHINERY customers' production processes.

Cutting unit for aluminium strip perforated machine

Depending on customer market requirements, perforated sheet metal often needs to be cut to length. KINGREAL CEILING MACHINERY engineers will customize the aluminium strip perforated line with a cutting station based on the customer's specific requirements and perforated sheet metal design. This cutting unit ensures precise cutting, ensuring each perforated sheet metal piece meets the customer's specifications.

Recoiling unit for aluminium strip perforated line

After punching, customers often need to rewind the perforated sheet metal. To address this, KINGREAL CEILING MACHINERY offers a recoiler with various performance and parameters tailored to customer needs and perforated sheet metal design. This unit efficiently rewinds the perforated sheet metal for subsequent storage and transportation.

Additional units for aluminium strip perforated machine

To meet individual customer needs, aluminium strip perforated lines can be equipped with additional units such as unloading trolley, metal sheet cleaning machine, and vacuum scrap collection. These additional units further improve production efficiency, streamline operational processes, and ensure smoother operation of the entire aluminium strip perforated line.

Customized Aluminium Strip Perforated Line Manufacturing Solutions

| Processing Coils in Specific Width Ranges | KINGREAL CEILING MACHINERY aluminium strip perforated machines can process coils within a specific width range, tailored to customer needs, primarily targeting coils as wide as several tens of centimeters. KINGREAL CEILING MACHINERY also offers aluminium strip perforated line solutions for widths 700mm, 1300mm. The perforated metal sheets produced by these aluminium strip perforated machines are ideal for subsequent secondary processing, eliminating the need for re-slitting and other operations, creating more convenient production conditions for customers. |

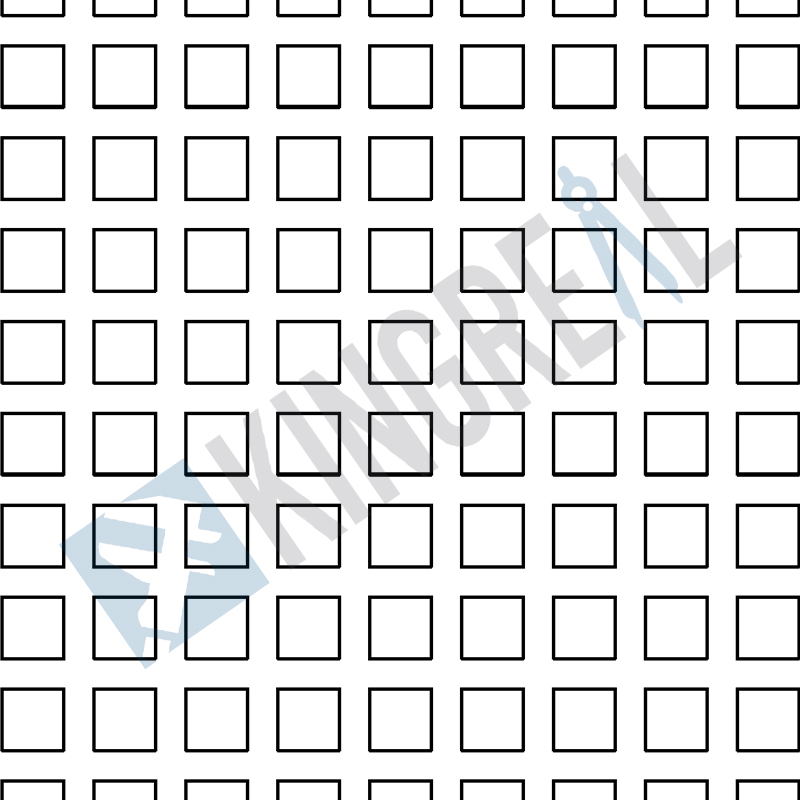

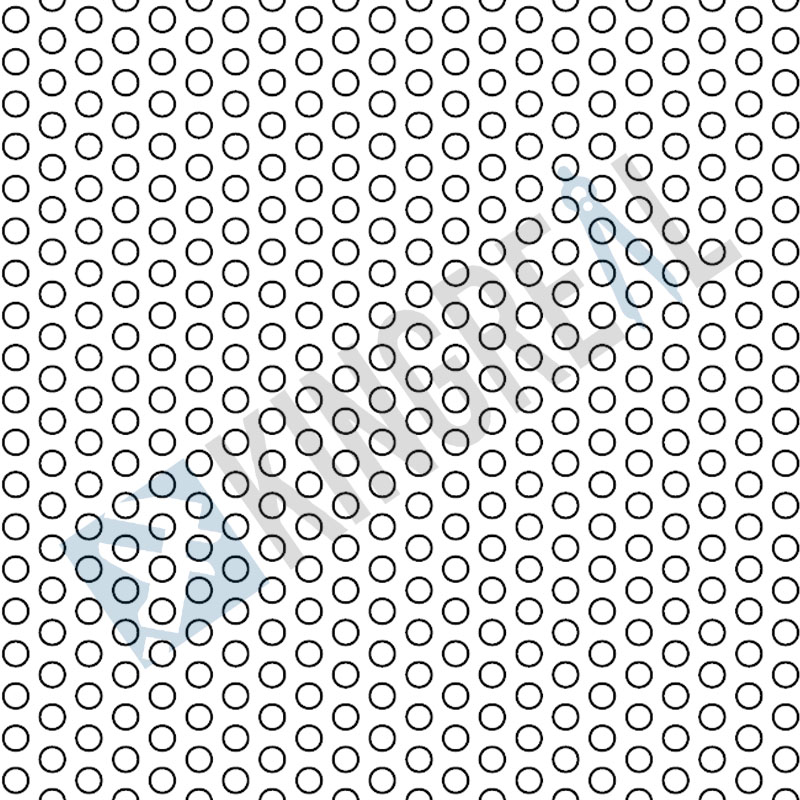

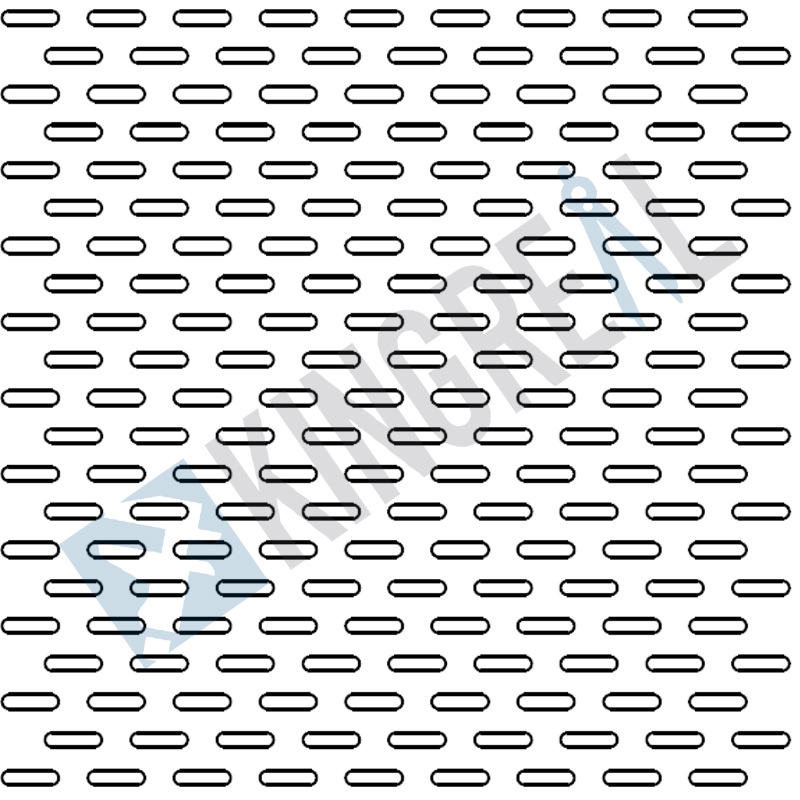

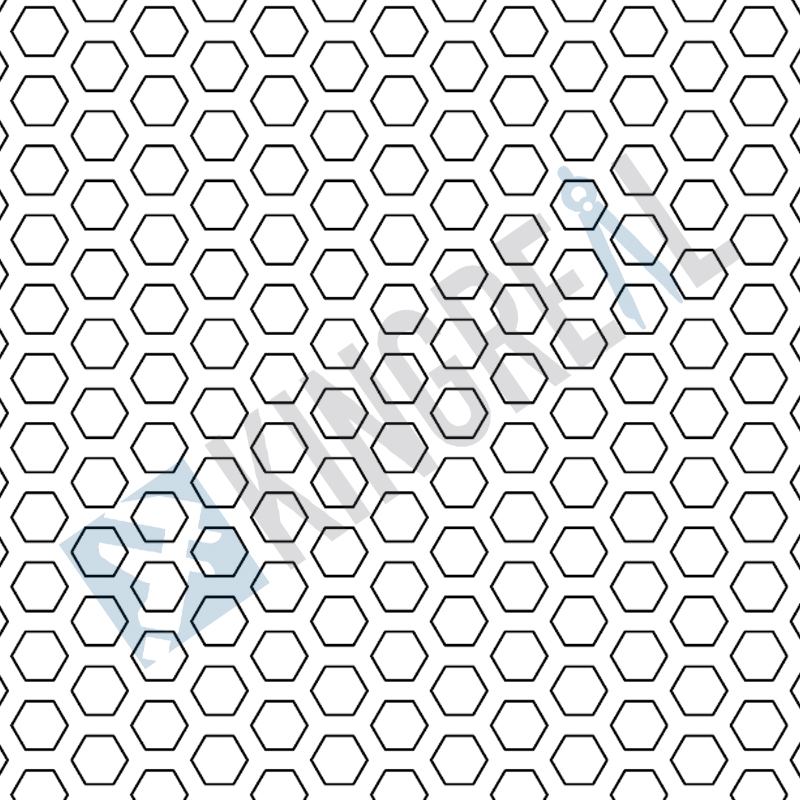

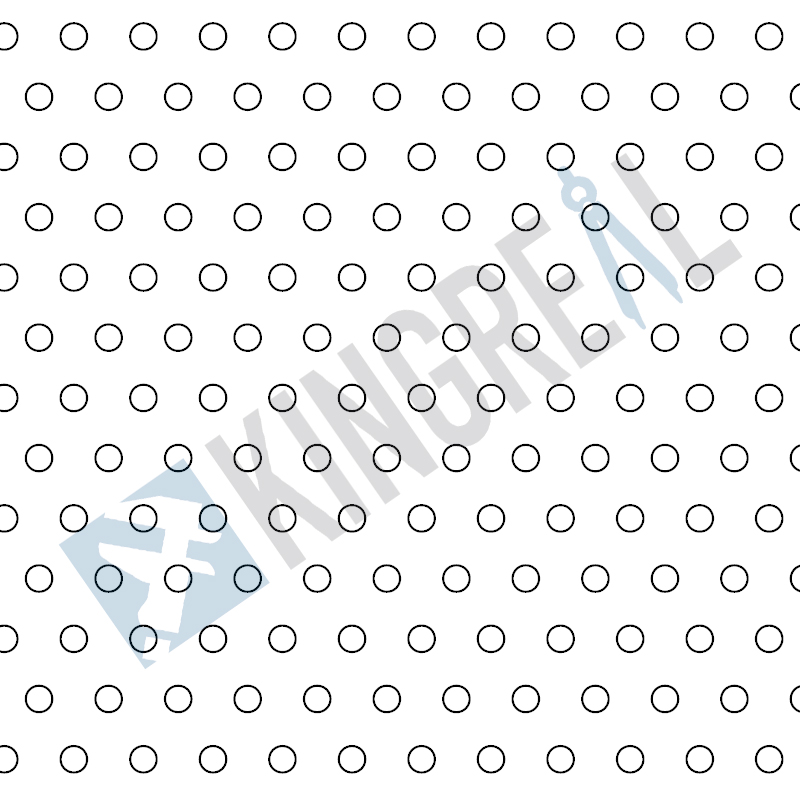

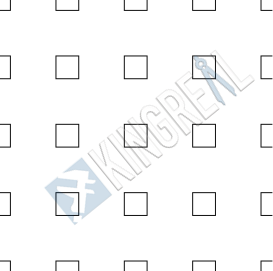

| Processing Different Hole Shapes | KINGREAL CEILING MACHINERY customizes punching dies based on customer drawings. The aluminium strip perforated lines can produce a variety of hole shapes, including round, long round, square, triangle, diamond, hexagonal, and crossed holes. By changing dies, KINGREAL CEILING MACHINERY aluminium strip perforated machines can produce a variety of hole shapes on the surface of metal coils using a single machine. |

| Processing Different Apertures | KINGREAL CEILING MACHINERY aluminium strip perforated machines can produce larger or smaller apertures according to customer needs. Notably, KINGREAL CEILING MACHINERY continuously innovates aluminium strip perforated line research and development, currently capable of punching apertures as small as 1.0mm and 1.5mm. These small-diameter punching dies are challenging to manufacture, requiring extremely high precision and material strength. Through sophisticated machining processes and high-quality materials, KINGREAL CEILING MACHINERY has successfully overcome this challenge, ensuring high-speed production while maintaining high precision and quality output. |

| Parameter Adjustment for Different Projects | KINGREAL CEILING MACHINERY does not offer standardized aluminium strip perforated machines, each one is custom-designed based on the customer's project. KINGREAL CEILING MACHINERY engineers adjust the parameters of each aluminium strip perforated line component to best meet the customer's needs. Furthermore, KINGREAL CEILING MACHINERY will consider adding additional components such as feeding trolley, metal sheet cleaning machine, and unloading trolley based on the customer's specific production needs, aiming to improve the efficiency and automation of the customer's overall production process. |

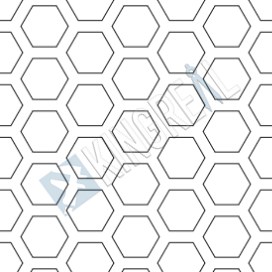

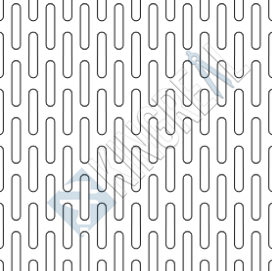

Hole Pattern Display

The following images illustrate the diverse hole patterns that KINGREAL CEILING MACHINERY aluminium strip perforated machines can produce. These hole patterns cover not only common circular, square, and triangular shapes, but also complex geometric shapes. KINGREAL CEILING MACHINERY is committed to providing high-quality aluminium strip perforated lines, paying close attention to every detail to ensure precise holes are punched into metal coils.

|  |  |  |  |  |  |  |

Ready to Start Your Aluminium Strip Perforated Line Project?

Before purchasing a aluminium strip perforated machine, please consider the following factors based on your specific project requirements and provide KINGREAL CEILING MACHINERY staff with as much detail as possible so they can quickly evaluate and provide you with a customized aluminium strip perforated line solution:

Material Specifications, Material Width, Material Thickness, Aperture, Tolerance, Surface Finish...

Through detailed consultation, KINGREAL CEILING MACHINERY will be able to tailor the most suitable aluminium strip perforated machine solution for you, ensuring your competitiveness in your production. Whether you are working on large-scale production or customizing small batches, KINGREAL CEILING MACHINERY aluminium strip perforated lines are the perfect fit for your production.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)