Metal Great Wall Plate Roll Forming Machine

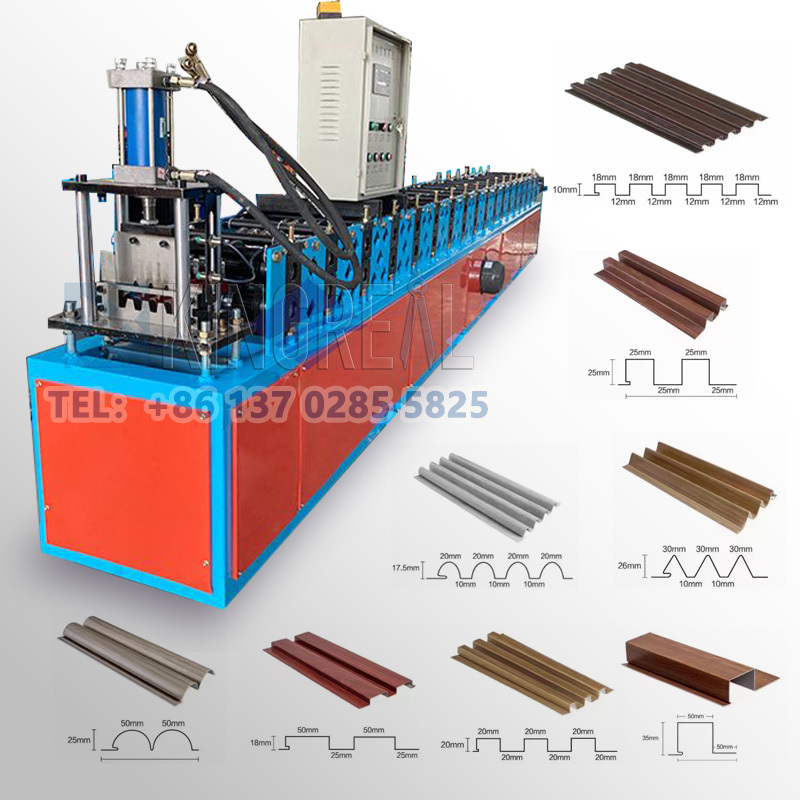

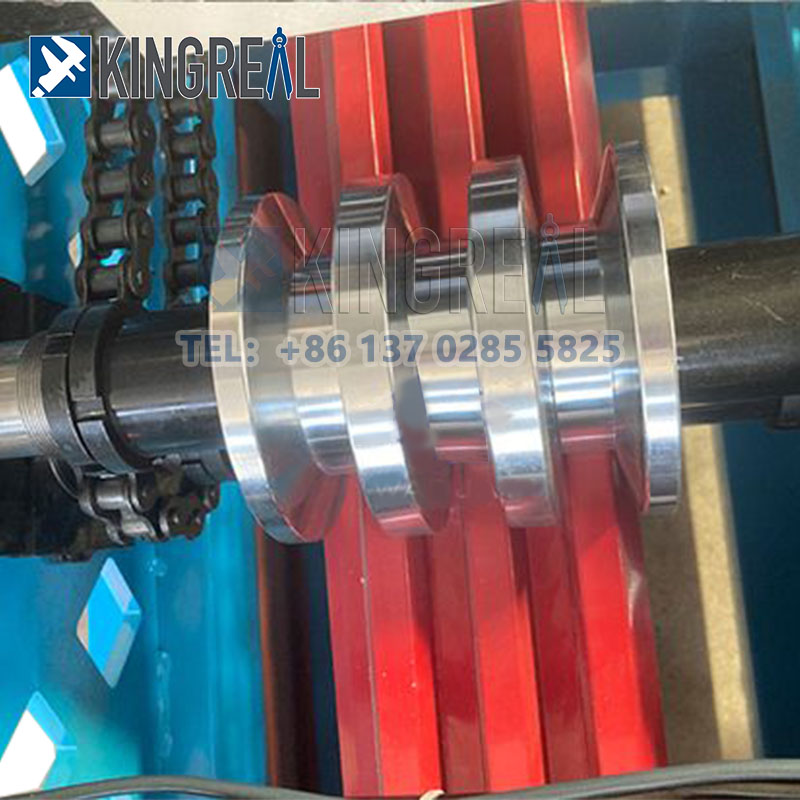

KINGREAL CEILING MACHINERY can provide the metal great wall plate roll forming machine, which realizes the rolling and squeezing of the barrel hoop rollers to gradually change its shape and finally form the desired shaped sheet.

- KINGREAL CEILING MACHINERY

- China

- 90 Days

- 9999

Details

Machine Description of Metal Great Wall Panel Machine

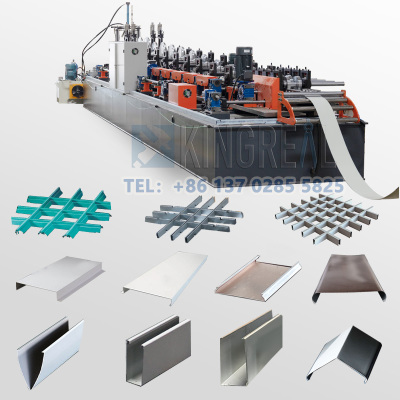

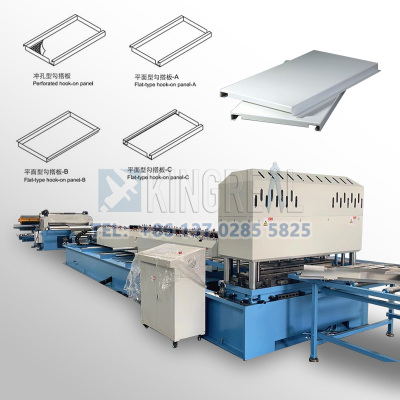

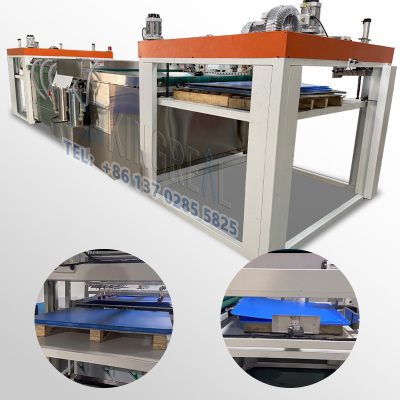

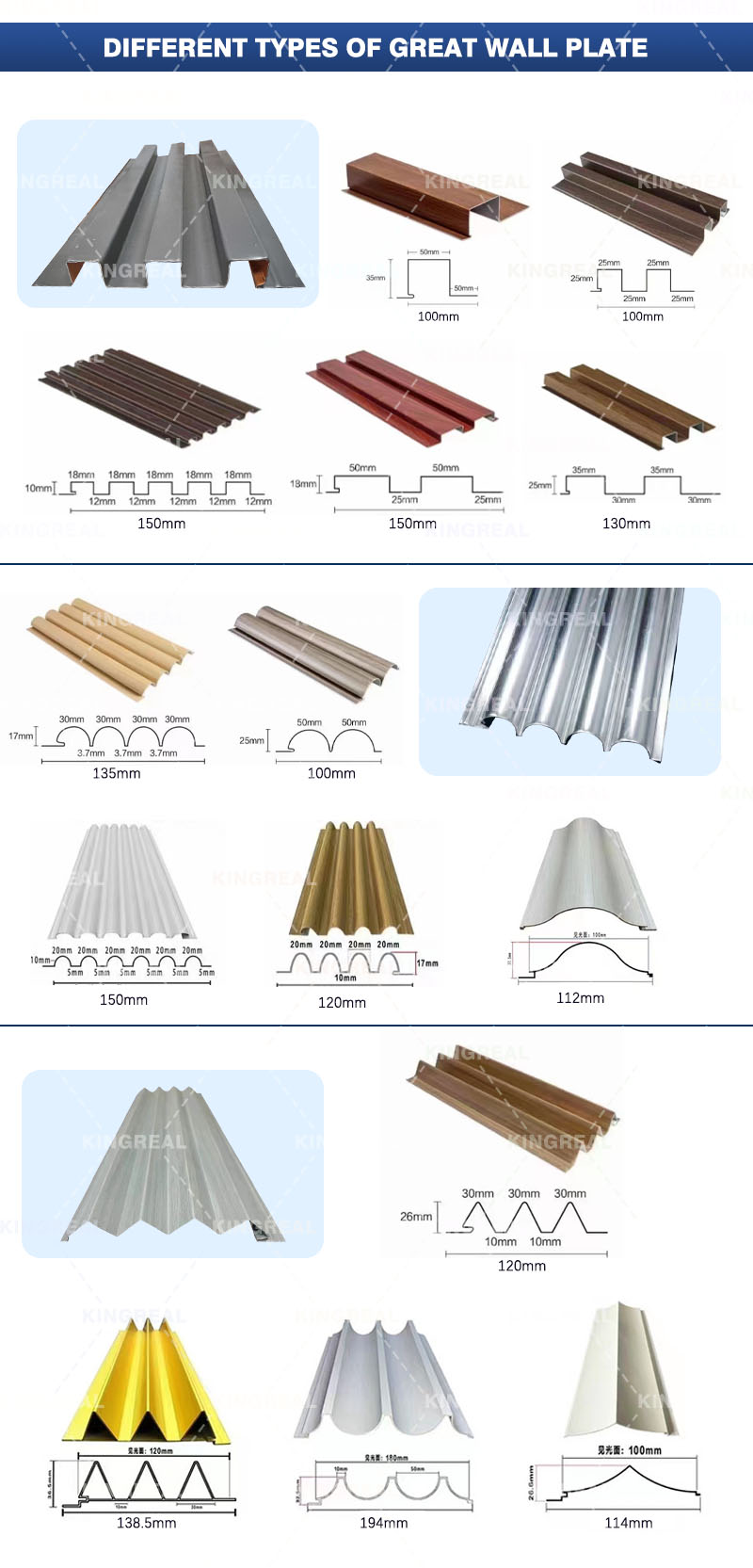

Adopting an advanced technology and techniques, KINGREAL CEILING MACHINERY metal great wall plate roll forming machine is capable of forming various shaped metal sheets through a series of processing steps, including curling, cutting, bending, punching and so on, and finally forming a variety of shaped metal great wall panels. The metal great wall panel machine is highly automated, capable of automatic feeding, positioning, forming and cutting operations, which greatly improves production efficiency and product quality. At the same time, the metal great wall panel machine is also multi-functional, can be adjusted and changed according to different shapes and sizes of metal great wall panel. Adopting advanced control system, it can realize precise operation and adjustment to ensure the stability and accuracy of the molding process. At the same time, the metal great wall panel machine also has good safety performance, equipped with safety guards and emergency stop devices to ensure the safety of operators. |  |

Technical Specification of Metal Great Wall Panel Machine

| Product Name | Great Wall Panel |

| Main machine power | 7.5 KW |

| Equipment weight | 4.6T |

| Core material | Galvanized sheet, color-coated steel sheet, etc |

| Material width | 1250mm |

| Material thickness | 25mm (Customizable) |

| Speed | 10m/min |

| Number of molding groups | 18 |

| Transmission | Servo gear |

| Molding Die | CR12 |

| Shearing method | Hydraulic shearing |

How Does Metal Great Wall Panel Machine Work?

Working Principle of Metal Great Wall Panel Machine: Aluminum alloy strip is processed into the shape of great wall panels through roll forming. First, the aluminum alloy strip is placed on a feeder rack. A feeder feeds the strip into the roll forming machine, where it is gradually rolled by multiple sets of rollers, bending the strip into the desired great wall panel shape.

Components of Metal Great Wall Panel Machine: Generally, it includes a feeder rack, a feeder rack, a roll forming machine, a shearing device, and a control system. The feeder rack is used to place the raw material; the feeder rack ensures accurate and stable feeding of the strip into the forming machine. The roll forming machine is the core component, consisting of multiple rollers whose shape and arrangement determine the Great Wall panel's shape. The shearing device is used to cut the formed Great Wall panel into the specified length. The control system automates the entire production process, controlling feed speed, roller rotation speed, and shearing length.

Advantages Of Metal Great Wall Panel Machine

(1)22 passes of molding

The metal great wall panel machine utilizes high-quality mold steel, and its 22-step forming process ensures excellent product flatness and straightness. The molds undergo a special treatment process, resulting in a service life of over 15 years, ensuring long-term stable production performance. The metal great wall panel machine 's advanced forming process ensures exceptional quality throughout each product.

(2)Automatic cutting for metal great wall panel machine

The metal great wall panel machine is equipped with a fully automatic hydraulic cut-to-length shear, enabling noiseless cutting, ensuring a quiet and efficient cutting process. This technology produces smooth cuts on the formed profiles, significantly reducing burrs, thereby enhancing subsequent processing convenience and overall product aesthetics.

(3)Strong flexibility metal great wall panel machine

The metal great wall panel machine can adjust the pressure and mold parameters to meet the processing needs of plates of different thicknesses and materials, and produce great wall panels of the specifications required by customers

(4)Selected high quality plaques

High-quality plaque equipment to increase the strength of the force. The molding process is more stable, improving the quality of products.

Features of Great Wall Panel

-Excellent thermal insulation for energy-efficient applications;

-Waterproof and UV-resistant in all climates;

-Concealed fasteners for seamless installation;

-Contemporary aesthetic for commercial and residential use.

Application Of Great Wall Plate

The Great Wall Panel Machine is widely used in the fields of construction, manufacturing, transportation and so on for manufacturing various shaped sheets, such as roof tiles, wall panels, door and window frames and so on. It is characterized by high production efficiency, simple operation and stable quality of finished products, which can meet the needs of different customers.

FAQ

1. What‘s your Warranty?

12 months except human error, during which all parts damaged because of quality problem will be changed for free.

Parts that are out of warranty will be provided in factory price.

2. What‘s your delivery Time?

Within 60-80 days after receiving prepayment. Some machines in stock can be delivered at any time.

3. What‘s your payment terms?

A 40% deposit is paid before production, the balance is paid after inspection confirmation before shipment.

4. What‘s your Install and Training?

If buyers come to our factory to inspect, the training to install and operate is provided face-to-face.

If not, a manual book and video are provided to show how to install and operate.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)