Metal Powder Spray Coating Line

KINGREAL CEILING MACHINERY provides fully automated metal powder spray coating lines designed to apply powder coatings to various metal products (sheets, profiles, parts, etc.), with features such as fast coloring and excellent adhesion.

- KINGREAL CEILING MACHINERY

- China

- 90 Days

- 9999

Details

Video About

Metal Powder Spray Coating Line

Introduction to Metal Powder Spray Coating Line

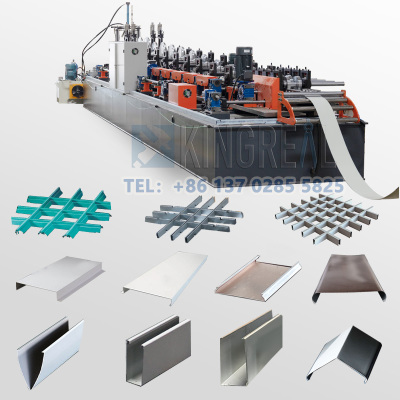

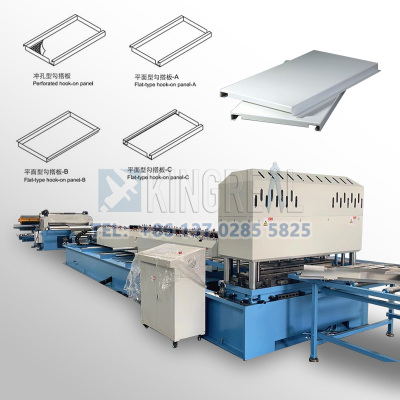

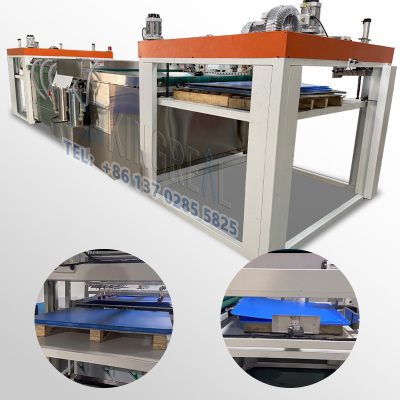

KINGREAL CEILING MACHINERY metal powder spray coating line is an efficient spraying solution specifically for different types of metal products, including metal sheets, metal profiles and metal parts. KINGREAL CEILING MACHINERY metal powder coating spraying line uses powdered thermosetting polymers, plastics and additives, and uses electrostatic spraying (ESD) technology to evenly spray the powder onto the metal surface to form a hard colored coating. The key to this process lies in the chemical properties of the powder. After heating, the powder is tightly bonded to the metal surface to form a strong molecular structure. This coating not only enhances the corrosion resistance of the metal, but also improves its visual effect. This metal powder spray coating line is widely in demand in the global market, especially in countries such as the United States, the Netherlands, Australia, Brazil, Canada and Germany. |  |

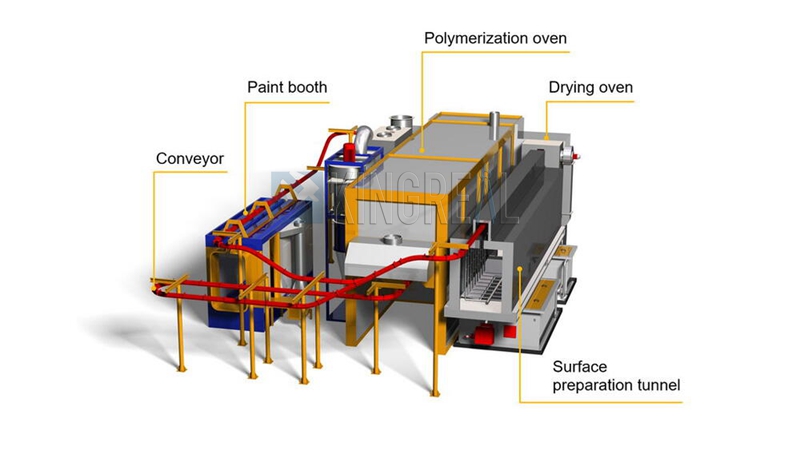

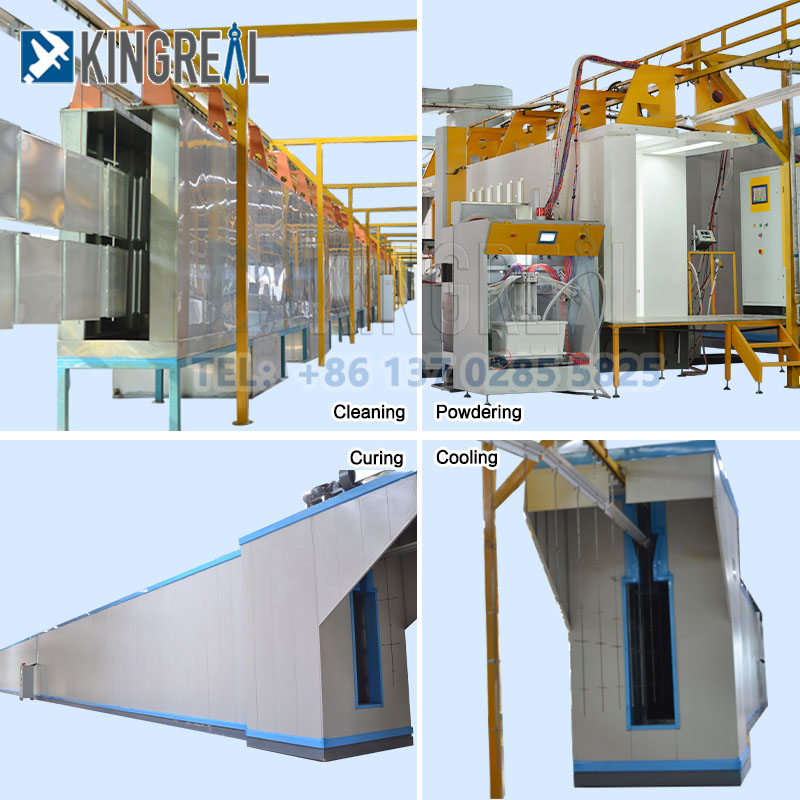

Working Process of Metal Powder Coating Spraying Line

The workflow of KINGREAL CEILING MACHINERY metal powder spray coating line is carefully planned to ensure that every link is efficient and accurate. First, the metal products to be treated will pass through the surface treatment cleaning line on the conveyor line to remove oil, dirt and rust in preparation for subsequent powder spraying. Depending on different quality standards, the cleaning line can spray iron phosphate, zinc phosphate, nanotechnology or lubricating chemicals.

Next, the cleaned and treated materials will enter the drying oven for thorough drying to ensure that the surface moisture is completely removed, thus preparing for powder spraying. In the powder spraying room, the metal products will be evenly sprayed using advanced equipment to ensure that each product surface is covered with powder. After the spraying is completed, the metal products will be sent to the oven with preset temperature and time for powder curing. During this process, the powder will be transformed into a solid coating, and finally discharged from the unloading area of the conveyor after cooling, marking the successful completion of the entire metal powder coating spraying line workflow. |  |

Advantages of Metal Powder Coating Spraying Line

1.Metal powder spray coating line that can be installed in the workshop By installing the metal powder coating spraying line directly inside the workshop, the company can make full use of the existing production space and no longer need to rely on external companies for coating. This design enables companies to efficiently complete the powder coating of metal products in their own factories, avoiding the various risks and inconveniences of transporting products to the coating plant. Customers do not have to worry about metal parts being damaged during transportation due to frequent handling, thereby maintaining the integrity and quality of the product. 2.Metal powder spray coating line with independent production plan control By not relying on outsourcers, customers can independently control production plans, which significantly reduces the cost of spraying and handling. Enterprises can flexibly adjust the coating time and process according to their own production rhythm, avoiding production delays or cost increases caused by external dependence. At the same time, controlling the production plan also enables enterprises to better manage inventory and resource allocation, thereby improving overall production efficiency. This autonomy not only improves the operational flexibility of enterprises, but also provides strong support for enterprises in the fierce market competition. |  |

3.Adaptable metal powder coating spraying line KINGREAL CEILING MACHINERY metal powder coating spraying line is designed with excellent adaptability, whether the customer needs to spray small or large parts, it can meet the requirements of different sizes and shapes. KINGREAL CEILING MACHINERY metal powder spray coating line can be flexibly adjusted to meet the changing market needs. This design ensures that enterprises can quickly adapt and maintain efficient production capacity when facing a diverse product line. 4.Metal powder spray coating line with adjustable production capacity KINGREAL CEILING MACHINERY metal powder coating spraying line has excellent production capacity adjustability. According to the specific product coating procedures, KINGREAL CEILING MACHINERY engineers will accurately design the conveyor's running speed and rationally plan the activity area for each process stage. This meticulous planning ensures an efficient production process, allowing each link to be smoothly connected and maximizing production efficiency. Whether it is mass production or small batch customization, customers can flexibly adjust according to their own needs and effectively respond to market changes. |  |

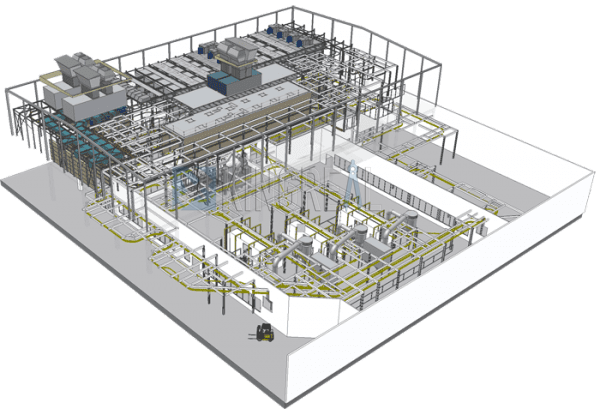

5.Compact layout metal powder spray coating line KINGREAL CEILING MACHINERY metal powder coating spraying line features a compact layout design with flexible structural configuration, which can be customized according to the specific conditions of the customer's factory. This design ensures that the metal powder spray coating line can operate effectively in any shape of room, regardless of the size or shape of the space, KINGREAL CEILING MACHINERY can provide customers with suitable solutions. |  |

Benefits of Powder Spraying

Improve durability: The powder spraying process significantly improves the durability and color fastness of metal products, allowing them to maintain good appearance and performance in various environments.  Eliminate the defects of traditional processes: Compared with traditional painting processes, the powder spraying process eliminates confusion and imprecision, ensuring that each product can meet high standards of quality requirements. Spray Coating Options KINGREAL CEILING MACHINERY metal powder coating spraying line is suitable for a variety of metal materials, including but not limited to: carbon steel, stainless steel,galvanized steel, aluminum, copper, nickel, brass, iron. KINGREAL CEILING MACHINERY metal powder spray coating line also provides a rich color selection to meet the personalized needs of customers. Some standard colors include: black, white, red, blue, green, etc. Customers can choose the appropriate color according to product use and market demand. KINGREAL CEILING MACHINERY engineers will also give professional advice. |  |

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)