Plano Type Perforated Metal Machine

KINGREAL CEILING MACHINERY plano type perforated metal machine can meet your needs for various punching patterns and perforated metal applications.

- KINGREAL CEILING MACHINERY

Details

↜Video About Plano Type Perforated Metal Machine

↜Introduction to Plano Type Perforated Metal Machine

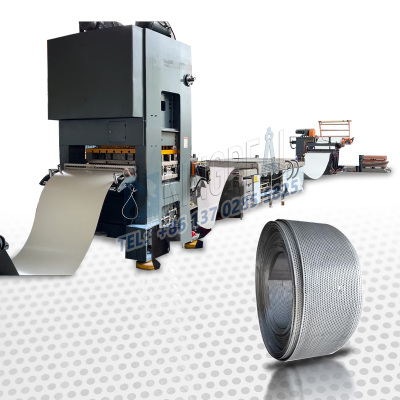

KINGREAL CEILING MACHINERY plano type perforated metal machines, also known as across perforated metal machine, are custom-designed according to customer project requirements, featuring high-performance parameters and flexible production capabilities. Through meticulous design and customized manufacturing of punching dies, KINGREAL CEILING MACHINERY plano type perforated metal making machines can adapt to the processing needs of different metal materials, especially suitable for high-volume, high-speed production. KINGREAL CEILING MACHINERY plano type perforated metal machines mainly employ two processes: one is punching followed by shearing to produce perforated sheets; the other is punching followed by coiling to produce perforated coils. Both processes are suitable for processing materials in the thickness range of 0.4-2.0mm, ensuring that customers can flexibly choose the machine solution that best meets their project needs. With extensive industry experience, KINGREAL CEILING MACHINERY plano type perforated metal making machines can provide customers with perforated metal sheets in various shapes, including round, square, slotted, and customized shapes according to specific requirements. These plano type perforated metal machines have been widely used in various industries.

Working Process of Plano Type Perforated Metal Machine

Decoiler -- Leveling Machine -- Punching Machine -- Cutting Station -- 2nd Leveling Machine (Optional)

↜Parameters of Plano Type Perforated Metal Machine

| Material | Galvanized sheet and other metal materials |

| Thickness | 0.4-2.0mm |

| Material Width | 100-1300mm |

| Speed | Maximum 220 SPM |

| Hole Diameter | 2.0~10.0mm |

| Hole Type | Common round holes, square holes, slotted holes, or customized |

↜Advantages of Plano Type Perforated Metal Machine

1) Wide Application

The perforated materials produced by KINGREAL CEILING MACHINERY plano type perforated metal making machines, after subsequent secondary processing, can be used to create exquisite perforated finished products, widely used in many fields. For example:

-Filtration industry: Manufacturing perforated filter elements.

-Construction industry: Producing perforated baffle ceilings and perforated wall panels, enhancing the aesthetics and functionality of buildings.

-Automotive industry: Manufacturing high-precision products such as motorcycle mufflers.

-Food processing industry: Manufacturing bread trays for the production process of baked goods.

This wide range of applications fully demonstrates the versatility of the plano type perforated metal machine, allowing customers to meet their needs in different industries.

2) High-Speed Punching

Using multi-row stamping dies, KINGREAL CEILING MACHINERY plano type perforated metal making machine can achieve high-speed operation, with a maximum speed of 220SPM. Compared to traditional single-hole punching methods, the KINGREAL CEILING MACHINERY plano type perforated metal machine eliminates the need to punch each hole individually, significantly improving production efficiency.

3) Support for Switching Between Different Hole Shapes/Diameters

Based on customer design drawings, KINGREAL CEILING MACHINERY can customize one or more sets of punching dies. This allows for switching between different hole shapes and diameters during production by changing the punching dies. KINGREAL CEILING MACHINERY is committed to providing flexible solutions to adapt to customers' ever-changing market demands.

4) Customized Plano Type Perforated Metal Making Machines

KINGREAL CEILING MACHINERY understands that every customer's needs are unique; therefore, the parameters and performance of the plano type perforated metal machine are fully customized according to customer requirements. KINGREAL CEILING MACHINERY solutions can equip the plano type perforated metal making machine with additional components to further improve production efficiency:

-Metal sheet cleaning machine: Improves material surface cleanliness and ensures the high-quality appearance of the final product.

Feeding and unloading trolleys: Improve the efficiency and automation of the entire production process.

2nd leveling machine: Further improves the flatness of the material surface.

5) Meeting Micro-Hole Punching Requirements

The KINGREAL CEILING MACHINERY team can manufacture micro-hole punching dies capable of punching holes as small as 1.0 mm. These micro-holes are crucial in some specialized industries, placing higher demands on die design and manufacturing, a challenge that the KINGREAL CEILING MACHINERY technical team is fully capable of meeting.

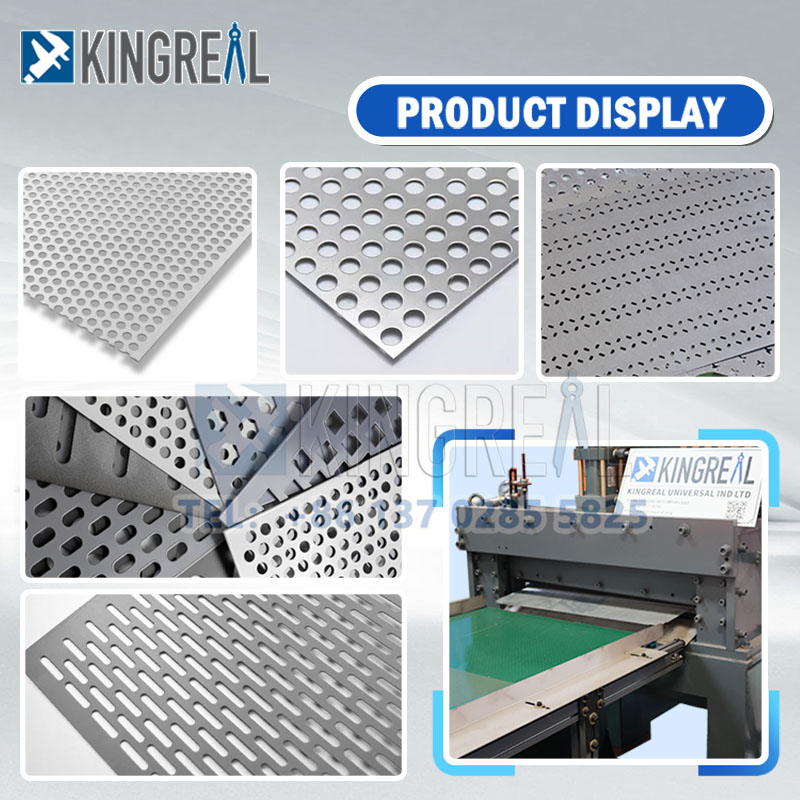

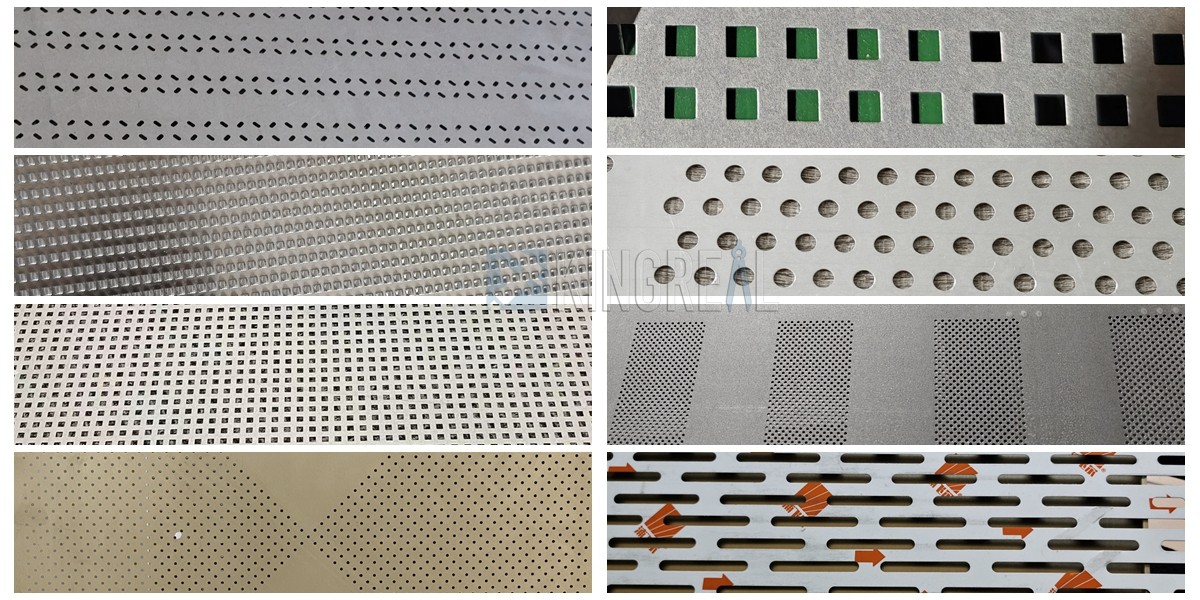

↜Customized Design Patterns

The KINGREAL CEILING MACHINERY team provides customized punching dies based on the customer's specific needs. The plano type perforated metal machine can handle common hole shapes such as round holes, square holes, slotted holes, and some special hole shapes. For different arrangements of the same hole shape, KINGREAL CEILING MACHINERY can precisely design the plano type perforated metal making machine and dies in combination. KINGREAL CEILING MACHINERY engineers will compile the technical parameter requirements for the punching dies, including maximum punching force, press compatibility range, and die weight.

The following shows some finished hole shapes and diameters produced by KINGREAL CEILING MACHINERY in collaboration with customers on plano type perforated metal machine projects. KINGREAL CEILING MACHINERY welcomes you to learn more, or if you have other special hole shapes or diameters that need to be produced, you can submit your drawings directly to the KINGREAL CEILING MACHINERY team, and we will provide professional advice and plano type perforated metal making machine manufacturing solutions.

↜Project Experience

KINGREAL CEILING MACHINERY has accumulated extensive experience in the design and manufacturing of plano type perforated metal machines. Over the years, KINGREAL CEILING MACHINERY has successfully collaborated with clients from all over the world, including Iran, Bangladesh, Morocco, Brazil, Saudi Arabia, and Greece. Therefore, the KINGREAL CEILING MACHINERY team is more adept at meeting customer needs, thus reducing initial communication costs. For clients new to this field, KINGREAL CEILING MACHINERY can provide a comprehensive explanation of the basic knowledge of plano type perforated metal making machines and offer rational suggestions based on their project requirements. For clients who need to expand their production scale, KINGREAL CEILING MACHINERY plano type perforated metal machines will fully meet your needs for high-performance equipment. For example, the punching die customized for a Greek client can punch micro-holes as small as 1.0mm, demonstrating KINGREAL CEILING MACHINERY exquisite technology. At the same time, a plano type perforated metal making machine equipped with both a cutting station and a recoiler was designed for a Moroccan client, meeting their complex production needs.

↜Ready to Get a High-quality Plano Type Perforated Metal Machine?

Please inform KINGREAL CEILING MACHINERY of your specific production needs to receive a customized plano type perforated metal machine manufacturing solution.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)