KINGREAL CEILING MACHINERY After-sales Service

At KINGREAL CEILING MACHINERY, we are well aware of the importance of after-sales service in terms of customer satisfaction and machine performance. In order to ensure that customers can fully utilize KINGREAL CEILING MACHINERY equipment and maximize the service life of the machine, KINGREAL CEILING MACHINERY team of engineers provides detailed after-sales service. Whether in Saudi Arabia, Russia, Italy, Mexico, Canada, the United States and other places, KINGREAL CEILING MACHINERY engineers actively go to carry out machine installation, operation training, commissioning and maintenance.

After-Sales Service Solutions

KINGREAL CEILING MACHINERY after-sales team is dedicated to resolving all customer-related machine issues, including installation, troubleshooting, operator training, maintenance, and spare parts supply.

●Troubleshooting: KINGREAL CEILING MACHINERY team of experienced engineers provides rapid troubleshooting services both online and offline. When a customer suspects a machine problem, a KINGREAL CEILING MACHINERY engineer will first communicate with the customer via online video conferencing to observe the machine's operating status. This allows the KINGREAL CEILING MACHINERY engineer to promptly identify the issue and provide a solution.

If the problem is complex and requires on-site repair, KINGREAL CEILING MACHINERY will promptly dispatch an engineer to the customer's facility for on-site repair. KINGREAL CEILING MACHINERY goal is to resolve issues as quickly as possible, minimize downtime caused by machine failures, and ensure uninterrupted production operations.

●Spare Parts Supply

Over the long term, the supply and replacement of spare parts is inevitable. KINGREAL CEILING MACHINERY offers spare parts supply services for a wide range of machines. Whether it's blade wear or roller wear, KINGREAL CEILING MACHINERY can promptly ship replacement parts domestically to ensure the machine remains in top working condition, thereby guaranteeing production quality and precision.

For customers who chose semi-automatic machines due to smaller production scales, KINGREAL CEILING MACHINERY can also provide the necessary parts to upgrade their machines as their production scale expands and they require more automated machinery. For example, a customer from Saudi Arabia previously purchased a semi-automatic metal ceiling tile production line from KINGREAL CEILING MACHINERY. As their production scale expanded, they urgently needed a high-speed, fully automated metal ceiling tile production line. KINGREAL CEILING MACHINERY addressed the customer's needs by adding components such as a 2nd Precision Straightener, Flipping machine, Automatic tiles feeding machine, Auto Bending Forming Machine, successfully upgrading the semi-automatic metal ceiling tile production line to a fully automated one, improving production efficiency for the Saudi Arabian customer.

Diverse Machine Expertise

KINGREAL CEILING MACHINERY engineers are proficient in the operation and maintenance of a wide range of machines, including:

This wide range of expertise allows KINGREAL CEILING MACHINERY engineers to provide customers with targeted solutions to ensure the efficient operation of the machine.

Core content of after-sales service

1. Machine installation and commissioning

After the customer purchases the machine, KINGREAL CEILING MACHINERY engineers will personally go to the customer site to install and commission the equipment. This process is crucial because correct installation ensures the normal operation of the machine.

On-site installation: Engineers will perform precise installation based on the characteristics of the equipment and the customer's production environment. This includes not only the mechanical installation of the equipment, but also electrical connections and software configuration.

Commissioning process: After the installation is completed, the engineer will conduct a comprehensive commissioning of the equipment to ensure that all functions of the machine are operating normally. This process may include adjusting the feed speed, checking the cutting accuracy, and testing the overall efficiency of the production line.

2. Operation training

After the equipment is installed and debugged, KINGREAL CEILING MACHINERY engineers will provide systematic training for the customer's operators. The training content includes:

Operation manual: Engineers will provide detailed operation manuals to help workers understand the various functions and operation steps of the equipment.

Common problem solving: Engineers will inform workers in advance of common problems that may be encountered during the production process and provide corresponding solutions to ensure that workers can respond quickly when they encounter problems.

Daily maintenance guidance: The training also includes daily maintenance skills to help customers keep the equipment in the best condition and extend its service life.

Engineers' significant capabilities

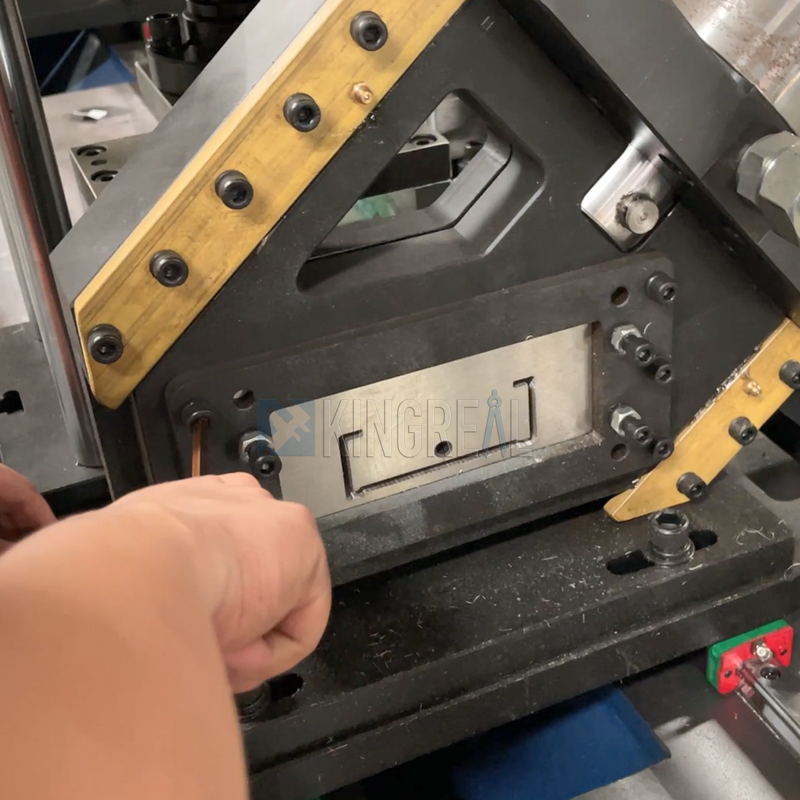

1.Manufacturing and replacement of punching dies

In terms of sheet metal perforation machines, KINGREAL CEILING MACHINERY engineers are not only able to replace punching dies, but also have the ability to manufacture dies. This ability gives them a deeper understanding of the installation and use of punching dies.

Customization of customer needs: The common punching die apertures on the market are 1.8mm and 2.5mm. Recently, in response to the special production needs of customers in Greece and Morocco, KINGREAL CEILING MACHINERY engineers have successfully designed and manufactured sheet metal perforation machines capable of punching out 1.0mm and 1.5mm micro-punching apertures. This innovation solves the challenges faced by customers in the production process and improves their production capabilities.

Global installation experience: KINGREAL CEILING MACHINERY engineers have also traveled to Brazil, the United Arab Emirates, Turkey, Saudi Arabia and other countries to install and debug punching dies to ensure that customers can fully utilize the advantages of this sheet metal perforation machine.

2.Replacement of hangers and blades of roll forming machines

KINGREAL CEILING MACHINERY engineers have also performed well in guiding customers to replace the hangers and blades of roll forming machines.

Hanger replacement: For example, KINGREAL CEILING MACHINERY ceiling t bar machine can produce different sizes of ceiling t grids by replacing the hanger. In addition, the 3 in 1 false ceiling channel machine can produce U-shaped, L-shaped and Omega profiles by replacing the hanger. This flexibility not only improves the efficiency of false ceiling channel machine use, but also meets the diverse production needs of customers.

Blade replacement guidance: Engineers will provide detailed guidance to customers on how to correctly replace blades and ensure that the installation of blades meets safety standards. This training not only improves customers' operating skills, but also reduces equipment failures caused by improper blade replacement.

3.Machine installation and guidance

KINGREAL CEILING MACHINERY engineers also have rich experience in installing machines and providing guidance.

On-site installation: For customers who purchase metal ceiling machines, baffle ceiling machines, u channel machines, wall angle profile machines, omega channel machines, grilyato ceiling machines, sheet metal perforation machines and other equipment, KINGREAL CEILING MACHINERY engineers will personally go to the site for installation. This process ensures that the equipment can be put into use in the best condition.

Operation guidance: After the installation is completed, KINGREAL CEILING MACHINERY engineers will provide detailed training to operators and provide operation manuals to inform them in advance of situations and solutions that they may encounter during the production process. In addition, engineers will also teach customers how to perform daily maintenance to ensure the long-term operation of the equipment.

2025 Machine Installation

At KINGREAL CEILING MACHINERY, engineers have successfully helped multiple international customers install and debug machines, and have been highly recognized by customers.

●Open Cell Ceiling Machine Installation in Russia

In March 2025, KINGREAL CEILING MACHINERY engineers visited the Russian customer's factory to install an open cell ceiling machine. Upon arrival, the KINGREAL CEILING MACHINERY engineers first visually inspected all machine components and, after confirming they were in good condition, began installation of the entire line.

After the open cell ceiling machine was installed, KINGREAL CEILING MACHINERY engineers configured the PLC control panel according to the customer's production requirements. This step ensured the open cell ceiling machine could produce according to the Russian customer's specifications and meet the specific production parameters. KINGREAL CEILING MACHINERY engineers then tested the metal coils to ensure the open cell ceiling machine's proper functioning.

During the training phase, KINGREAL CEILING MACHINERY engineers emphasized how to produce different open cell ceiling sizes using a single open cell ceiling machine. Operators simply need to modify or set the desired grilyato ceiling size on the PLC control panel, and the open cell ceiling machine's forming rollers automatically adjust the width. During the trial run, KINGREAL CEILING MACHINERY engineers also assembled the produced open cell ceilings on-site to verify the accuracy of the finished product. This series of training and testing ensured that the Russian customer's workers were quickly up to speed and could begin production smoothly.

●Steel Perforated Machine Installation in Morocco

In September 2025, KINGREAL CEILING MACHINERY provided installation services for a steel perforated machine for a Moroccan customer. After the steel perforated machine arrived at the customer's factory, KINGREAL CEILING MACHINERY engineers quickly traveled to Morocco to install it. After the steel perforated machine was installed, KINGREAL CEILING MACHINERY engineers conducted detailed training to ensure the Moroccan workers were proficient in operating the steel perforated machine.

The training covered how to change punching dies so that a single steel perforated machine can produce perforated sheet metal with varying hole shapes and diameters. KINGREAL CEILING MACHINERY engineers also provided detailed instructions on proper steel perforated machine operation and routine maintenance, and provided an operating manual. This training and information not only improved the Moroccan workers' operational skills but also effectively extended the steel perforated machine's lifespan, ensuring stable operation.

Get the latest price? We'll respond as soon as possible(within 12 hours)