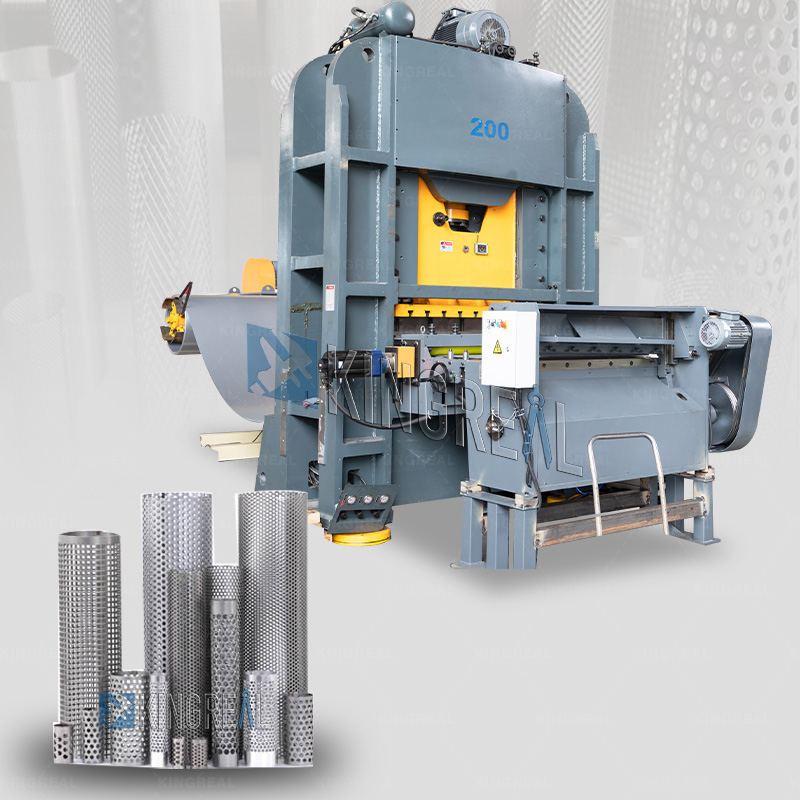

Metal Punching Machine For Metal Filter

Metal Sheet Perforated Machine For Metal Filter is one of our featured product. KINGREAL CEILING MACHINERY Metal Sheet Perforated Machine is designed for perforated coils. Coils of different materials are punched into different hole shapes through different dies and finally rewind up.

The rewind perforated coil can roll forming as metal perforated filter, baguette pan and etc..

- KINGREAL CEILING MACHINERY

Details

Video Display About Metal Perforated Machine

Metal Perforated Machine For Metal Filter Description

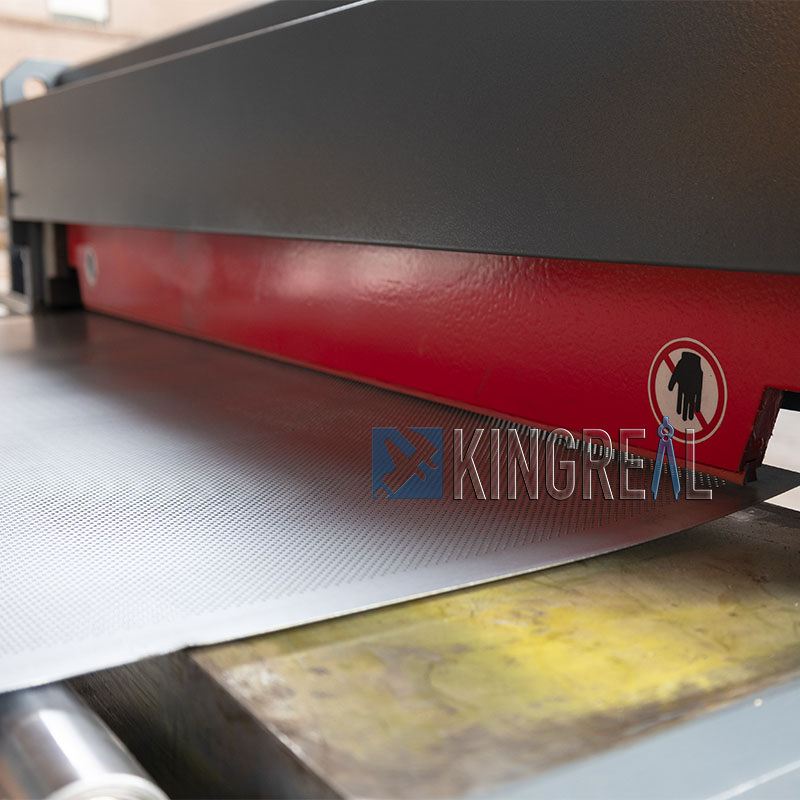

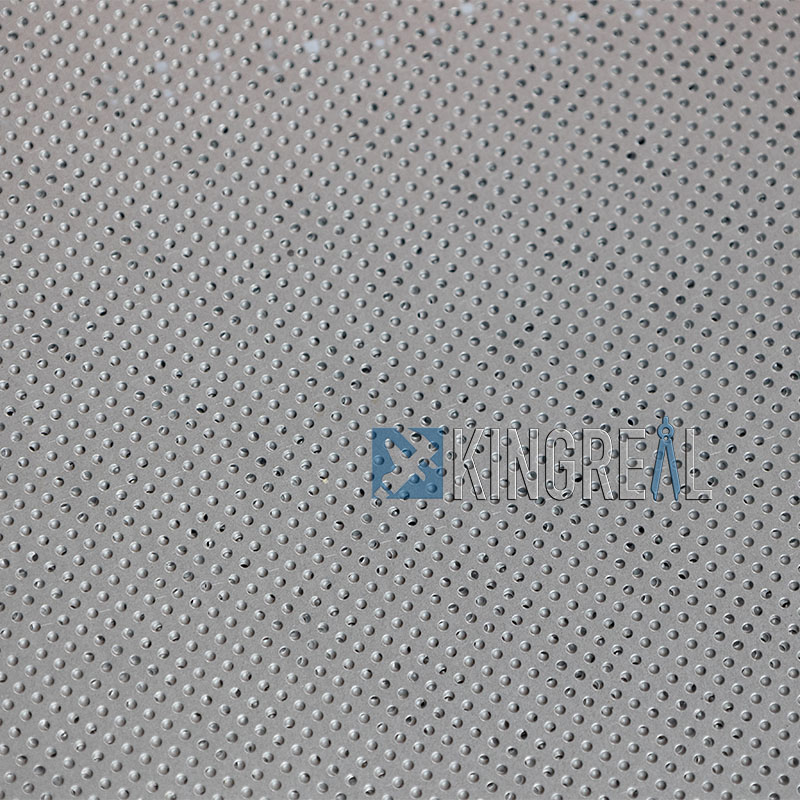

KINGREAL CEILING MACHINERY high speed Metal Perforated Machine is used for producing different kinds of perforation coil or panel, raw material can be stainless steel, alloy aluminum, galvanize steel and etc. Usually, according to the general market demand, the metal sheet perforated machine can process metal coils with a thickness range of 0.4-1.0mm. If you have special metal coil thickness requirements, please consult KINGREAL CEILING MACHINERY. KINGREAL CEILING MACHINERY will tailor it for you and provide a personalized manufacturing plan for the metal sheet perforated machine. And it can punch holes as small as 1mm! Nowadays, the market demand for perforated metal coils is growing rapidly. For example, many perforated filter manufacturers and baguette pan manufacturers are in great need of metal perforated machine to complete the punching process or directly purchase perforated coils as raw materials. The metal sheet perforated machine has the characteristics of fast punching speed, high degree of automation, and high punching accuracy. |  |

Technical Specification of Metal Perforated Machine

| Capacity | 1250kN |

| Nominal Stroke | 3mm |

| Slide Stroke | 20mm |

| Working Speed | 100-180 SPM |

| Max. Die Height | 420mm |

| Die Height Adjustment | 50mm |

| Main Motor Power | 18.5KW |

| Air Pressure | 0.5mm |

| Weight | About 11000kg |

Main Components of Metal Perforated Machine

Trolley of loading coil Hydraulic decoiler Straightener Feeding system Hydraulic press Different perforation molds Shear system Hydraulic units Electronic control systems Coil exit car |  |

Advantages of Metal Perforated Machine

01 Flexible Metal Sheet Perforated Machine

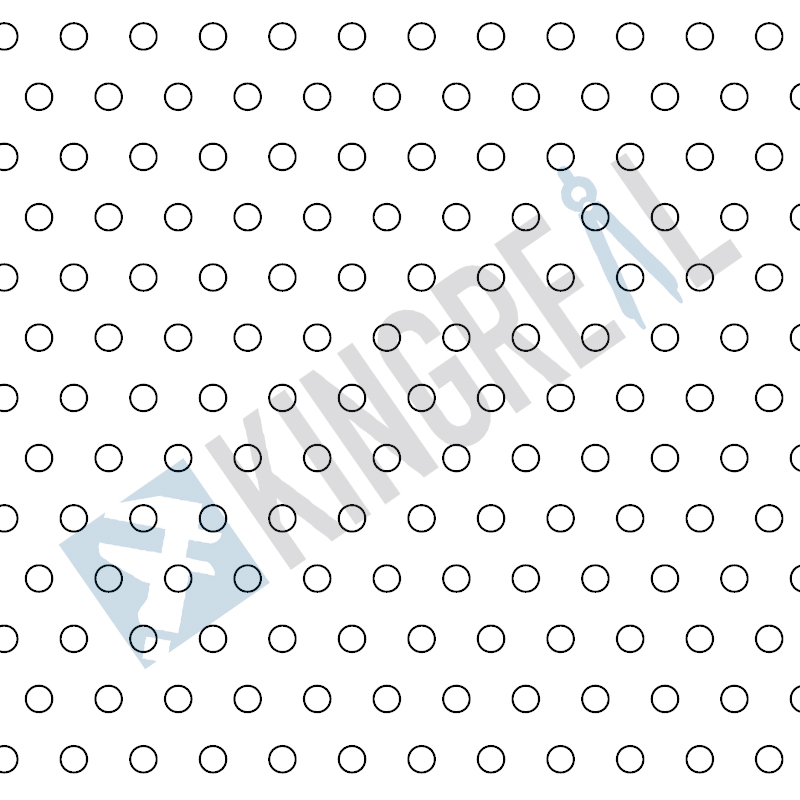

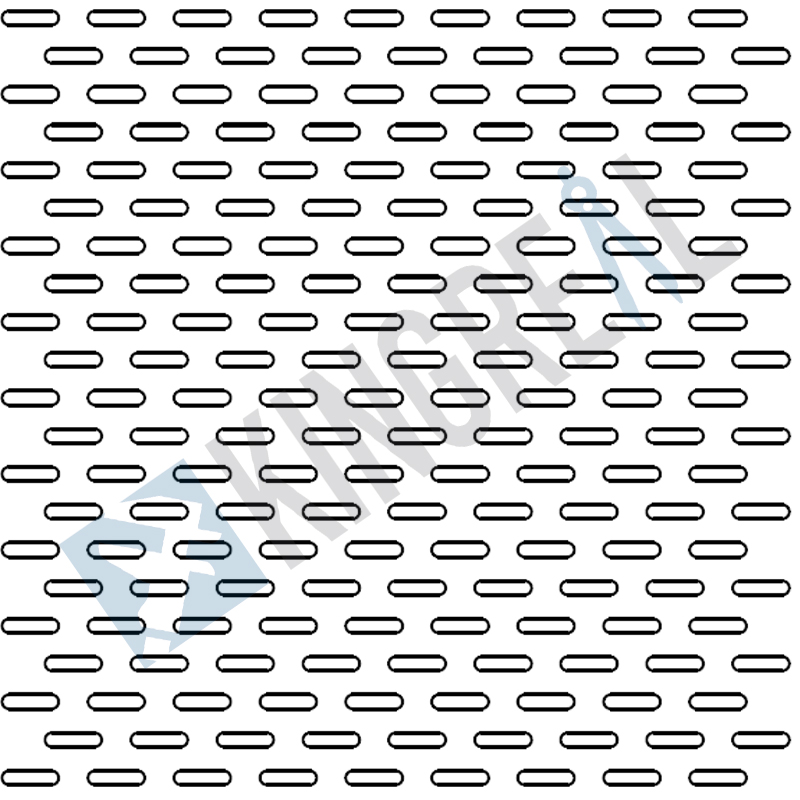

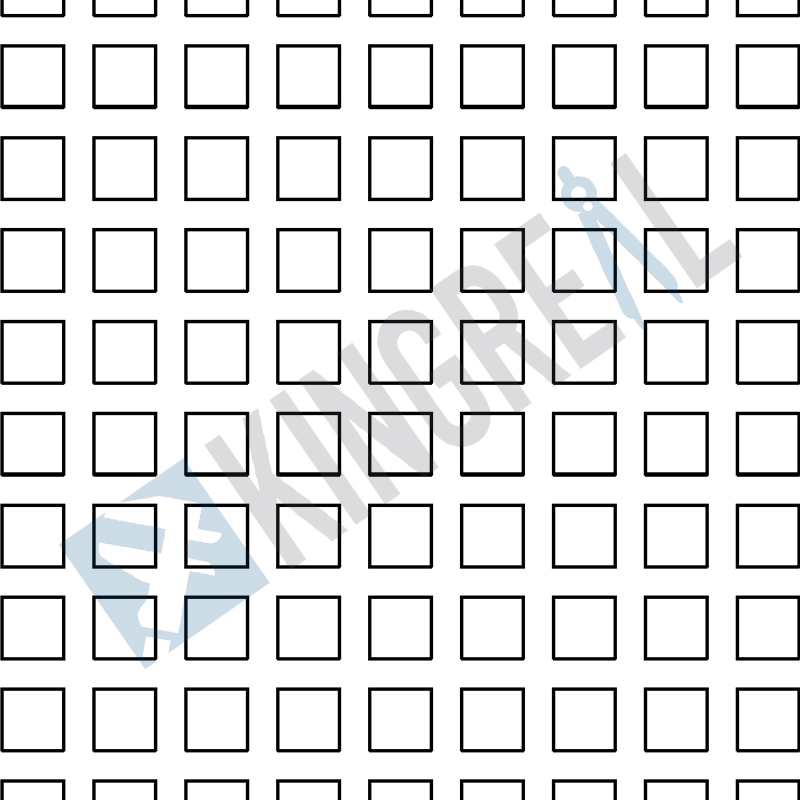

①Hole Types: The metal sheet perforated machine can punch the coil or plate into round holes, square holes, hexagonal holes, and other hole shapes. If your next process has different production needs, KINGREAL CEILING MACHINERY metal perforated machine is the best choice.

②Feed Materials: The feed material of KINGREAL CEILING MACHINERY metal perforated machine can be coil or cutted steel material. And the raw material can be aluminum sheet, galvanized steel sheet, stainless steel sheet, and etc, if you want to get the complete list of compatible materials, please feel free to contact us.

02 Adjustable Aperture for Metal Sheet Perforated Machine

The punched apertures can be as small as 0.7mm to 3mm or even larger. The most common sizes are from 1,5 mm to 2,5 mm, the distance between the holes is usually from 4 to 6 mm. Just set the parameters on the electronic control system than the metal punching machine can punch automatically.

03 Cutting Design for Metal Sheet Perforated Machine

As a professional metal sheet perforated machine manufacturer, KINGREAL CEILING MACHINERY also can provide complete punching solution. The perforated coil can be accurately cut according to the customer's preset length through the cutting station and used as the perforated raw material for the next process.

Successful Project -- Metal Sheet Perforated Machine

This customer from Iran visited the KINGREAL CEILING MACHINERY factory last year accompanied by KINGREAL CEILING MACHINERY staff. He personally visited the operation of the metal sheet perforated machine and experienced the operation of the metal sheet perforated machine and the inspection process of the finished product on site. Through this in-depth field visit, the Iranian customer has a full understanding of the working principle and production process of the metal sheet perforated machine. After having a preliminary understanding of the metal sheet perforated machine, KINGREAL CEILING MACHINERY staff invited him to the office for a more in-depth discussion to explore the manufacturing plan for the metal sheet perforated machine. Considering the needs of this Iranian customer, he hopes to produce high-precision perforated sheets for subsequent secondary processing and manufacturing of metal filters. In order to let Iranian customers have a more intuitive understanding of the quality of KINGREAL CEILING MACHINERY metal sheet perforated machine, KINGREAL CEILING MACHINERY staff specially demonstrated the metal filters produced by the metal sheet perforated machine and subsequently processed. After seeing the actual samples, Iranian customers were very satisfied with the processing accuracy that the metal sheet perforated machine can achieve, and finally reached a cooperation intention. |  |

Personalized Metal Sheet Perforated Machine Manufacturing Solutions

01 Customized metal sheet perforated machine solutions

KINGREAL CEILING MACHINERY has rich experience and professional technical capabilities in providing customers with customized metal sheet perforated machine solutions. KINGREAL CEILING MACHINERY is well aware that the production needs of each customer are unique, so we will flexibly adjust the parameters and performance of the metal sheet perforated machine according to the customer's actual production situation and combined with detailed drawings to ensure that the specific requirements of the customer are met.

In the customized solution, KINGREAL CEILING MACHINERY will fully consider multiple factors such as hole type, material width, material type and material thickness, and provide suitable metal punching machine tonnage. In addition, KINGREAL CEILING MACHINERY will also carry out personalized design and manufacture of punching dies according to the drawings provided by customers to ensure the accuracy and consistency of the hole type.

02 Customization options for auxiliary equipment

In order to further meet the production process needs of customers, KINGREAL CEILING MACHINERY will also equip the metal sheet perforated machine with auxiliary equipment such as cutting stations or recoilers. These configurations can not only improve production efficiency, but also optimize the production process, making the final product more competitive in the market.

If customers have more special needs, KINGREAL CEILING MACHINERY is also happy to provide additional customized options, such as feeding trolleys, metal sheet cleaning machines, etc. These flexible configuration options enable KINGREAL CEILING MACHINERY to build an efficient, accurate metal sheet perforated machine that meets the specific needs of customers.

Hole Drawings

Perforated Metal Filter

Perforated metal filter tube is widely used in various industrial fields. Its advantages are diverse and have brought significant benefits to many industries. Its main advantages are as follows:

● Excellent filtration effect: Its structure can effectively intercept and remove impurities, particles and suspended matter in the fluid. This highly efficient filtration capability makes metal mesh filters an indispensable piece of equipment in many industrial processes.

● High strength and durability: The metal material makes it have excellent pressure resistance and corrosion resistance. At the same time, it is not easily deformed and damaged, greatly extending its service life and reducing maintenance costs.

● Good washability and reusability: When a certain amount of impurities accumulate on the perforated metal filter surface, it can be cleaned to restore its filtration performance and extend its service life.

FAQ About Metal Sheet Perforated Machine

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)