How is metal perforated making machine?

2025-05-23 17:00

In today's competitive market, many manufacturers who are waiting and considering whether to buy a metal perforated making machine will think about a question, or ask around: "How about the perforated metal machine?" As a metal perforated making machine supplier with more than 20 years of rich experience, KINGREAL CEILING MACHINERY has close cooperation with many countries such as Indonesia, Bangladesh, the Philippines, the United Arab Emirates, Egypt, India, etc. This article will answer this question in detail and provide answers for more customers who have questions in this regard.

Brief Introduction to Perforated Metal Machines

| Perforated metal machines are industrial equipment specially used to punch out the hole type and aperture required by customers on the surface of metal coils. It is mainly used in many industries such as construction, automobiles, and home appliances, and can produce various types of metal products. Usually, the metal perforated making machine is mainly composed of multiple components such as decoilers, leveling machines, punching machines, shearing stations or recoilers. These components work together to make the punching process efficient and accurate. During the production process, the metal coil is first unwound by the decoiler to ensure the flatness of the material. Subsequently, the leveling machine further adjusts the flatness of the material to ensure the accuracy of subsequent punching. The punching machine is the core equipment, which forms the required hole shape on the metal surface through a high-pressure punch. Finally, the product is processed by a shearing station or a recoiler to complete the entire punching process. |

Main Types of Perforated Metal Machines

KINGREAL CEILING MACHINERY can provide three main metal perforated making machines according to customer requirements for different production processes. In addition, for specific needs, we can also equip the perforated metal machine with equipment such as feeding trolleys, metal sheet cleaning machines, and acoustical ceiling tile textile stick machines to improve production efficiency and meet customer personalized needs.

1) Coil to coil perforation line

After completing the punching, this coil to coil perforation line automatically rewinds the product, which is convenient for subsequent long-distance transportation or making finished products such as perforated baffle ceilings and bread trays. This design not only improves production efficiency, but also reduces the trouble of manual handling, and is suitable for large-scale production.

2) Sheet metal perforating machine

The sheet metal perforating machine is equipped with a shearing station, which can be accurately cut according to the customer's preset length. In this way, after the punching is completed, the product can be directly made into perforated wall panels, perforated silencers, etc., to meet customers' special requirements for finished product size.

3) Perforated metal ceiling panel machine

This perforated metal ceiling panel machine can be used with the metal ceiling machine to produce a variety of different sizes and types of perforated metal ceilings, such as 30x30cm, 60x60cm, 60x120cm, etc. This perforated ceiling not only has good sound insulation, but also meets the needs of different customers.

For customers who have a strong demand for sound insulation, KINGREAL CEILING MACHINERY can also equip them with an acoustical ceiling tile textile stick machine, so that the sound insulation cloth can be pasted on the metal ceiling immediately after the punching is completed.

Advantages of Perforated Metal Machine

The reasons for choosing the metal perforated making machine are not only technical considerations. The following are some significant advantages of the perforated metal machine:

1) Improve production efficiency

Through fast punching, the metal perforated making machine can significantly shorten the production cycle. Compared with traditional manual punching, the high efficiency of the perforated metal machine enables enterprises to meet more order requirements in a shorter time and improve overall production capacity.

2) Reduce labor costs

The metal perforated making machine has a high degree of automation, which can significantly reduce labor demand. In traditional production, processes that rely on a large number of manual operations are prone to human errors, while the perforated metal machine reduces manpower input, labor costs and error rates through automated design.

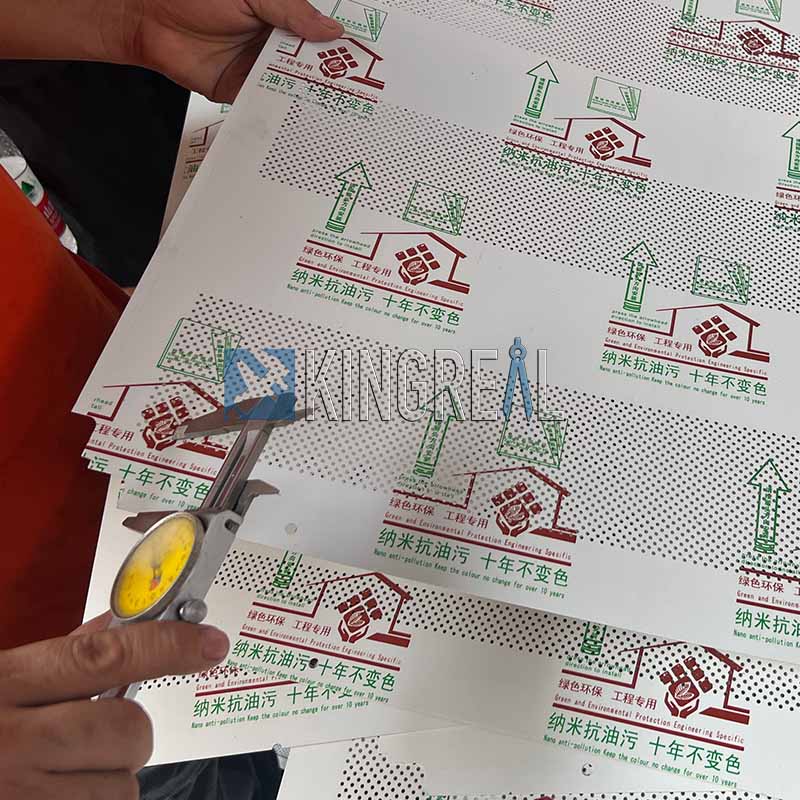

3) Ensure product quality

During the punching process, the metal perforated making machine can ensure the accuracy of the hole position and the consistency of the size. This high-precision punching capability ensures the quality of the finished product and meets the strict requirements of customers in different applications.

Considerations for Choosing a Perforated Metal Machine

When purchasing a metal perforated making machine, customers need to consider multiple factors to ensure that the selected equipment can meet production needs:

Production needs

Choose the right perforated metal machine according to the product type and material. Different industries and applications have different requirements for the performance, speed and accuracy of the metal perforated making machine. Understanding your own needs is the first step in choosing the right equipment.

Equipment performance

Pay attention to the punching speed, accuracy and durability of the perforated metal machine. Efficient and stable equipment can bring higher production efficiency and lower maintenance costs to enterprises.

After-sales service

It is very important to choose a supplier that provides good after-sales support. KINGREAL CEILING MACHINERY provides professional installation and operation guidance services to ensure that customers have no worries when using the metal perforated making machine. KINGREAL CEILING MACHINERY is able to send engineers to the customer's factory for on-site support to ensure the smooth operation of the equipment.

When choosing a perforated metal machine, it is crucial to fully understand its functions and advantages. The metal perforated making machine can not only significantly improve production efficiency and reduce labor costs, but also ensure product quality, making the company invincible in the fierce market competition.

If you are considering purchasing a perforated metal machine, please contact KINGREAL CEILING MACHINERY. We will wholeheartedly provide you with professional services and support to ensure that you choose the most suitable metal perforated making machine to help you achieve higher production efficiency and better product quality.

Get the latest price? We'll respond as soon as possible(within 12 hours)