What affects the operating speed of metal ceiling machine?

2025-05-19 17:00

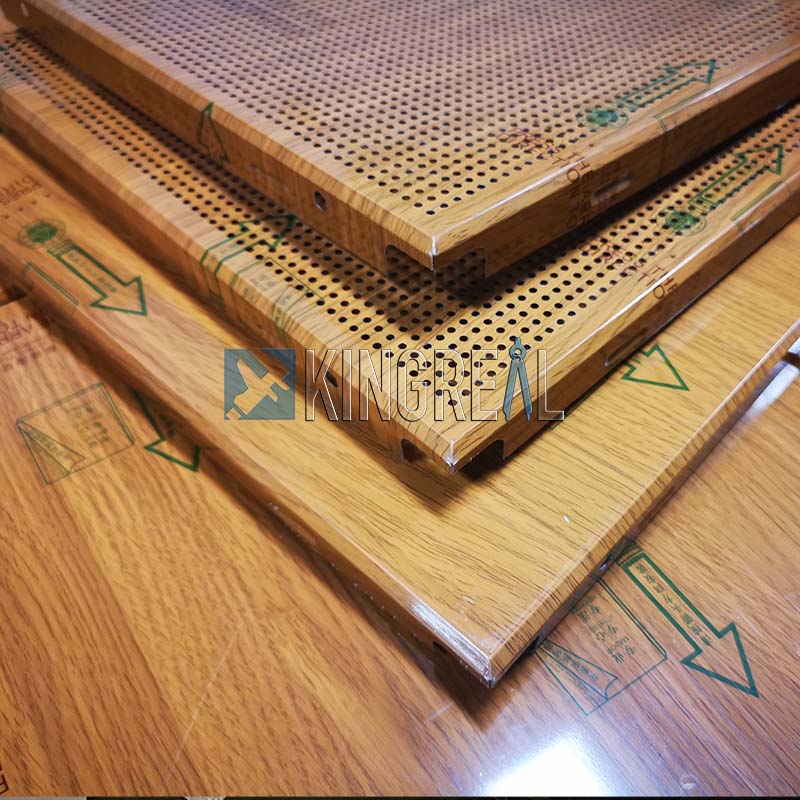

In the modern construction industry, metal ceiling tiles have won wide application with their superior performance and beautiful appearance. In order to meet market demand, the operating speed of metal ceiling machines has become the focus of customer attention. There are many factors that affect the operating speed of metal ceiling tile production lines, including punch speed, metal material, finished product size and metal ceiling machine type. This article will discuss in detail how these factors affect the overall efficiency of metal ceiling machines.

1.Punch Speed of Metal Ceiling Machine

| The punch press is one of the most important equipment in the metal ceiling machine, and its speed directly affects production efficiency. KINGREAL CEILING MACHINERY provides punch presses with various parameters, including 170 SPM, 200 SPM and 130 SPM. |  |

| 1.1 Definition of metal ceiling tile production lines' punch speed | The punch speed refers to the number of times the punch performs a punch per unit time, usually measured in hits per minute (SPM). A higher punch speed means that more punches can be completed in the same time, thereby speeding up the overall production progress. |

| 1.2 The impact of punch speed on production efficiency | Increase production capacity: When the speed of the punch increases, the number of punches will also increase. This directly leads to an increase in the output of the metal ceiling tile production line per unit time. Save time and cost: Faster punching speed shortens the production cycle, enables faster response to customer needs, and enhances market competitiveness. For example, using a 200 SPM punching machine, the production efficiency is significantly higher than that of a 130 SPM punching machine, making the company more flexible in production planning. |

| 1.3 Choose the right punching speed for metal ceiling tile production line | When choosing the punching speed of metal ceiling machine, the company needs to consider production needs, material properties, and equipment bearing capacity. Different types of metal ceiling machines may require different punching speeds to meet the production requirements of various products. |

2.Metal Material in Metal Ceiling Machine

| Metal material is another important factor affecting the operating speed of the metal ceiling tile production line. Common metal materials in metal ceiling machine include iron and aluminum. |  |

| 2.1 Comparison of processing speeds of aluminum and iron | Generally speaking, the same metal ceiling machine produces aluminum plates at twice the speed of iron plates. This is mainly due to the following reasons: Material properties: Aluminum has a lower density, the material is softer, and the punching and forming process is relatively easy. In contrast, iron has a higher hardness and requires greater force and longer time to process. Thermal conductivity: Aluminum has better thermal conductivity than iron. During the forming process, aluminum is more likely to deform at high temperatures, which improves production efficiency. |

| 2.2 Choose the right metal material for metal ceiling machine | When deciding which metal material to use in metal ceiling tile production line, companies should consider production costs, product performance, and market demand. For example, for metal ceiling tiles that require lightness and excellent sound insulation, aluminum may be more suitable; while for cost-sensitive projects, iron may be a better choice. |

3. Metal Ceiling Machines' Finished Product Size

| The finished product size is also an important factor affecting the speed of the metal ceiling tile production line. Common metal ceiling panel sizes include 300x300mm, 600x600mm, and 600x1200mm. |  |

| 3.1 The impact of size on production speed | Metal ceiling tiles of different sizes require different time and resources during the production process. Generally, the smaller the size, the faster the production speed. Small-sized metal ceiling tiles: For example, 300x300mm metal ceiling tiles can be produced faster due to their smaller size and require fewer punching and forming times. Small-sized metal ceiling panels usually have higher production speeds and are suitable for mass production. Large-size metal ceiling boards: Compared with small-size metal ceiling boards, 600x1200mm metal ceiling boards require more processing steps and time during the production process, which may lead to a decrease in production speed. This is because large-size metal ceiling tiles require more support and positioning, which increases the complexity of the operation. |

| 3.2 Production plan and market demand about metal ceiling machine | When formulating a production plan, enterprises should consider market demand and order conditions, and reasonably arrange the production of metal ceiling boards of different sizes to optimize production efficiency and resource utilization. |

4.Different Types of Metal Ceiling Machines

The type of metal ceiling tile production line directly affects the production speed. Generally, the more fully automated the metal ceiling machine, the faster its production speed, and vice versa.

4.1 Fully automatic metal ceiling tile production line The fully automatic metal ceiling machine achieves seamless connection of the production process through highly automated equipment. This metal ceiling tile production line is usually equipped with advanced automatic feeding systems, flipping machines, and auto bending forming presses and other efficient equipment, which can quickly complete multiple steps such as punching, cutting, and forming.

High efficiency: The high efficiency of the fully automatic metal ceiling machine is reflected in its fast production cycle and stable product quality. Due to the reduction of manual intervention, the operation of the metal ceiling tile production line is more stable and the failure rate is significantly reduced.

Flexibility: Fully automatic metal ceiling machines can quickly adjust production parameters according to different production needs, thus adapting to the production of ceilings of different types and sizes. |  |

4.2 Semi-automatic metal ceiling tile production lines In contrast, semi-automatic metal ceiling machines require more manual intervention and operation. Although its equipment configuration is similar to that of fully automatic metal ceiling tile production lines, workers are still required to make manual adjustments and controls in operation.

Slower production speed: Due to the intervention of manual operation, the production speed of semi-automatic metal ceiling tile production lines is usually lower than that of fully automatic metal ceiling machines. This may affect the company's responsiveness when facing large-scale orders.

Strong adaptability: Semi-automatic metal ceiling tile production lines are suitable for small batches and highly customized production needs, especially for new entrants to the market, which can reduce initial investment risks. |  |

There are many factors that affect the operating speed of metal ceiling machines, including punch speed, metal material, finished product size and metal ceiling machine type. For companies that want to improve the efficiency of metal ceiling tile production lines, it is crucial to have a deep understanding of these factors. By reasonably selecting punch speed of metal ceiling machine, optimizing material use, flexibly responding to finished product size and choosing the right type of metal ceiling machine, companies can gain an advantage in a highly competitive market.

When choosing metal ceiling machines, KINGREAL CEILING MACHINERY always provides customers with professional advice and customized solutions to ensure that the needs of different customers are met and help customers stand out in the market. Choosing KINGREAL CEILING MACHINERY metal ceiling tile production line will give you an efficient, flexible and reliable production experience.

Get the latest price? We'll respond as soon as possible(within 12 hours)