How does a mechanical press punch work?

2025-08-09 17:00

A mechanical press punch is a device that generates pressure through a mechanical transmission system and is primarily used to form sheet metal or other materials into desired shapes. Widely used in the metalworking sector, mechanical punch press machines provide stamping, blanking, perforating, stretching, coining, embossing, intricate forming, and bending.

1/ Working Principle of Mechanical Press Punch

A mechanical punch press machine converts circular motion into linear motion. Power from the main motor drives the flywheel, which in turn, via a clutch, drives components such as gears, a crankshaft (or eccentric gear), and a connecting rod, ultimately achieving linear motion of the slider.

This process requires a transition point between the connecting rod and the slider, typically a ball-type or pin-type (cylindrical) mechanism. These mechanisms convert circular motion into linear motion for the slider. The punch press applies pressure to the material, causing it to plastically deform, achieving the desired shape and precision.

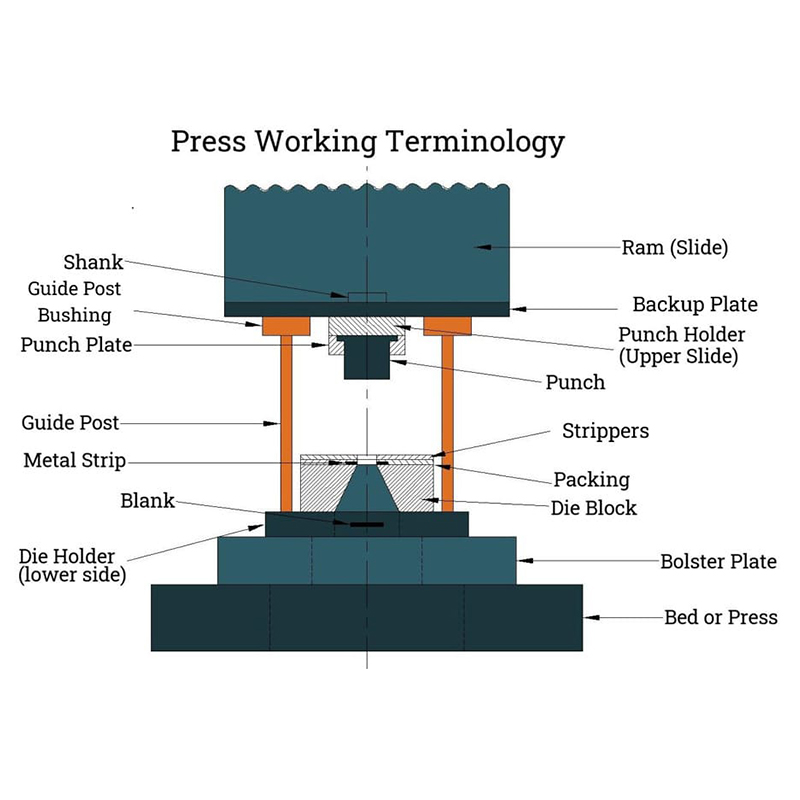

To achieve this, the mechanical press punch must be equipped with a set of dies (including an upper die and a lower die) to hold the material between them. The pressure applied by the machine deforms the material, while the reaction force is absorbed by the mechanical punch press machine's mechanical body, ensuring stable and precise processing. |  |

2/ Features of Mechanical Punch Press Machine

(1) High punch force for mechanical press punch

Stable and strong punching force from mechanical punch press machine guarantees effective performance in punching, blanking, and forming applications.

This high punch force enables punch presses to achieve optimal results when processing a variety of metal materials.

(2)Heavy-duty frame for mechanical press punch

Usually built with a strong frame to reduce deformation during use, mechanical punch press machines This stability not only increases the machine's life but also enhances machining precision.

(3)Efficient crankshaft system for mechanical press punch

Mechanical punch press machines are equipped with an efficient crankshaft system to ensure smooth, high-speed operation. This design reduces energy loss and vibration, thereby increasing productivity.

(4)Easy and safe operation for mechanical press punch

Typically fitted with an easy-to-use control panel, foot switch, and safety features to guarantee operator safety, modern mechanical punch press machine.

Moreover, the straightforward operational processes let staff members quickly learn how to use the mechanical press punch, hence lowering training expenses.

(5)Wide applications

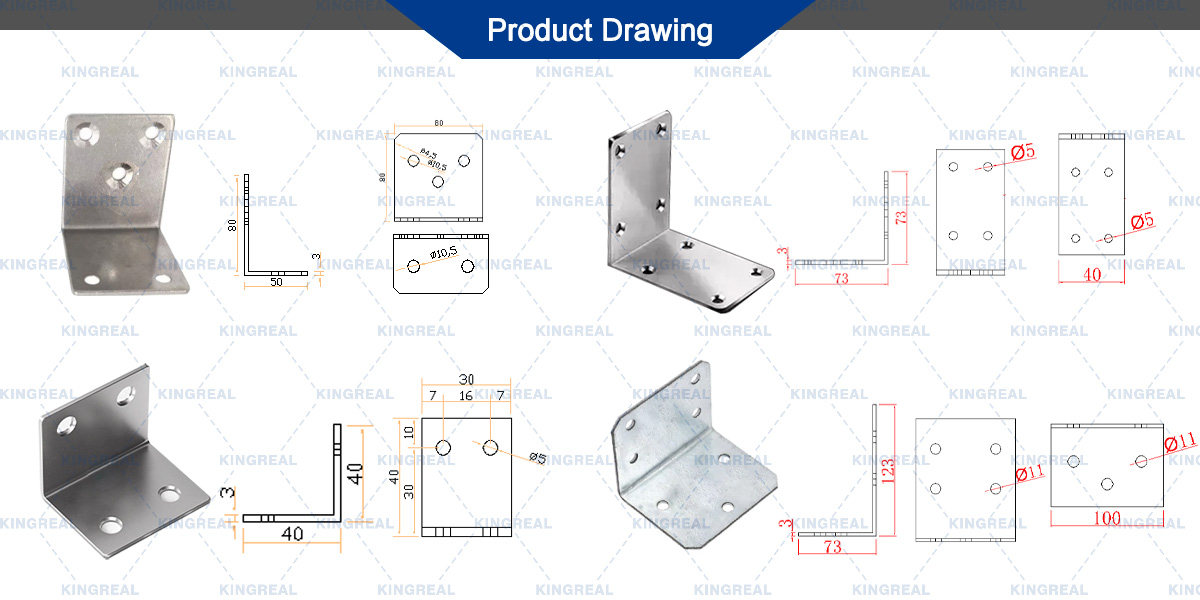

General sheet metal work, kitchenware, electronic components, hardware manufacturing, and automotive components all use mechanical press punches extensively. This makes mechanical punch press machine an essential component of the manufacturing sector.

(6)Low maintenance, cost-effective and efficient for mechanical press punch

Rational mechanical design reduces punch press operating costs while maintaining high output and stability. This makes mechanical punch press machines the preferred equipment for many metalworking companies.

3/ Different Types of Mechanical Press Punches

(1)Single Crank Press Machine & Double Crank Press Machine

●Single crank press machines transform rotating movement into linear action using a crank-connecting rod mechanism.Simple procedures like punching and blanking as well as small to medium size parts are appropriate for them.Usually economical, they are simple to run, maintain, and use.

●Double crank press machines, conversely, have two crankshafts usually placed at opposite ends of a broader slide.This design is appropriate for bigger part manufacture as well as applications requiring high tonnage since it offers more stability and accuracy, hence fulfilling more difficult manufacturing requirements.

Energy saved by a flywheel press punch is then sent to the punch via a mechanical gear system. A flywheel is turned by an electric motor, which then transmits energy to the punch through a clutch.

●Features of Flywheel Press Punch:

Provides continuous and stable power output, suitable for long-term, high-frequency punching operations.

Simple construction makes it suitable for small and medium-sized production needs. It is particularly well-suited for short-stroke, high-frequency stamping tasks and is widely used in the manufacture of small parts.

The C frame punch press features a "C"-shaped body with open sides and rear, facilitating die installation and workpiece loading and unloading.

●Features of C Frame Punch Press:

A large operating area allows for convenient access to the die from multiple directions.

It is suitable for handling small workpieces or complex dies, making it particularly well-suited for large-scale production.

It offers high flexibility and can accommodate frequent die changes.

The H frame punch press features an H-shaped structure with upright columns on the sides, making it suitable for heavy-duty metalworking tasks.

●Features of H Frame Punch Press:

The enclosed design provides increased rigidity and stability, making it suitable for heavy-duty stamping tasks.

It is suitable for high-precision heavy metal forming, bending, and stretching operations, and excels in industrial applications.

The high rigidity and low deformation make it superior in precision machining processes.

4/ Differences Between Hydraulic Punch Press and Mechanical Press Punch

The working rules of mechanical punch press and hydraulic press punch vary widely.Driven by a motor, mechanical punch presses employ a crankshaft to transform rotational movement into linear motion via a pulley.This arrangement causes great inertia, and usually they come in several kinds including single-stage and double-stage transmissions.

In contrast, hydraulic press punches utilize a cylinder stroke to achieve vertical linear motion, resulting in minimal inertia and some shallow drawing capabilities. While hydraulic press punches perform well in certain applications, pressure losses associated with fluid flow lead to relatively low efficiency and slow speeds, reducing productivity. Therefore, mechanical punch presses offer the simplicity and flexibility of a fast, compact hydraulic punch press.

Get the latest price? We'll respond as soon as possible(within 12 hours)