2025 | Metal Ceiling Tile Production Line

2025-08-07 17:00

1/ Video About Metal Ceiling Machine

2/ Description of Metal Ceiling Tile Production Line

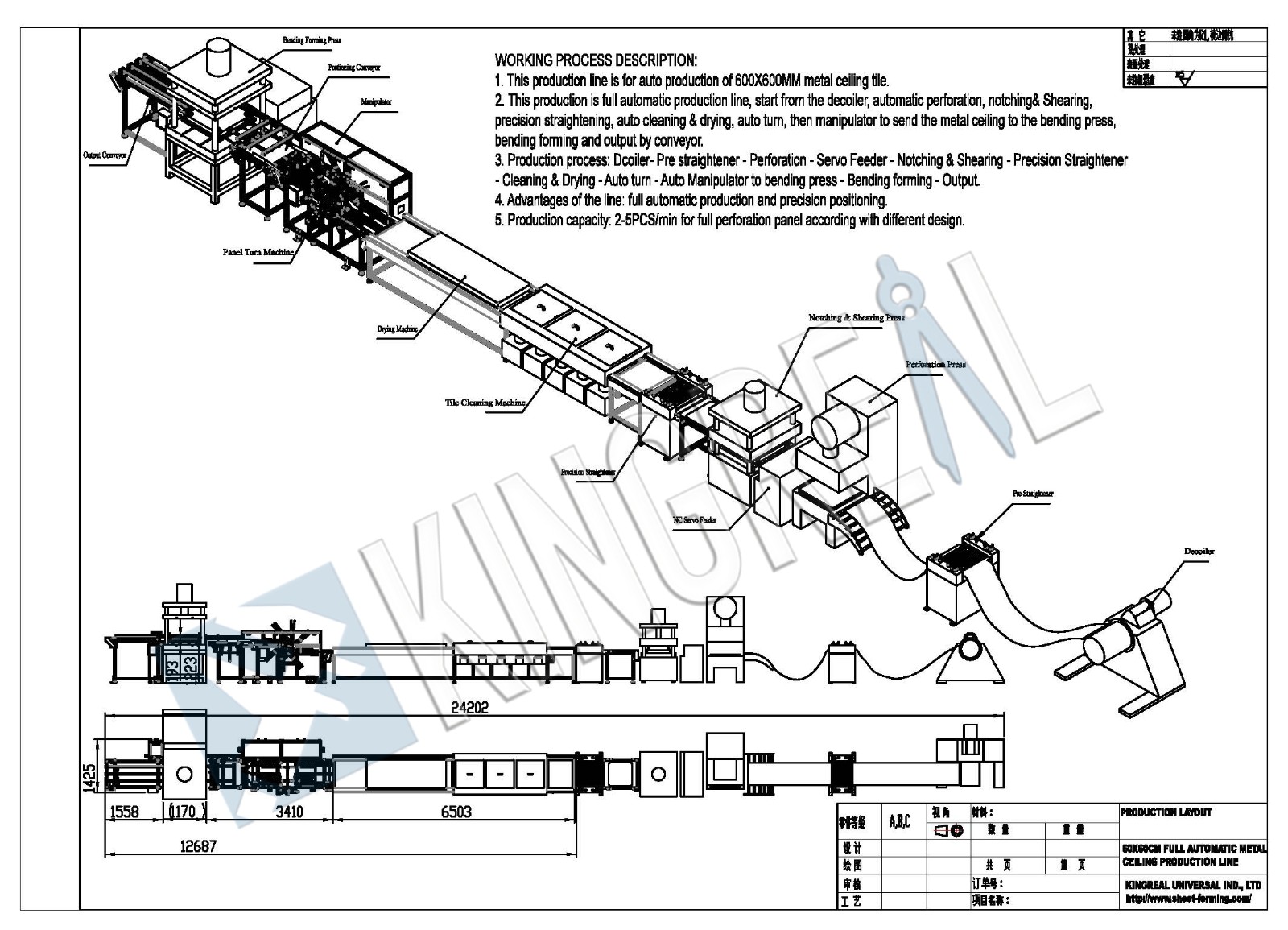

| A metal ceiling tile production line consists of numerous precision components, including an decoiler, a precision straightener, a perforation press, a servo feeder, a metal ceiling notching and shearing press machine(corner cut), a 2nd precision straightener, a tiles flipping machine, an automatic tiles feeding machine, a metal ceiling tile bending machine, and electrical and hydraulic systems.

These components work together to efficiently produce metal ceiling panels in various sizes, such as 300x300mm, 600x600mm, and 600x1200mm, as well as various styles, including clip in ceiling tile, lay in ceiling tile, and tegular ceiling tile.

It is precisely because of the perfect coordination of these precision components that a metal ceiling machine can efficiently manufacture metal ceiling panels of various specifications.

This article will delve into the metal ceiling tile making machine and its key components, providing a more comprehensive understanding of the working principles and practical applications of this advanced equipment. |  |

3/ Workflow of Metal Ceiling Tile Production Line

Fully automatic metal ceiling tile making machine:

Hydraulic Decoiler -- Precision Straightener -- Punching Machine -- Servo Feeding Machine -- Notching And Shearing Press (corner cut) -- 2nd Precision Straightener--Flipping machine-- Automatic tiles feeding machine--Metal Ceiling Tile Bending Machine

Semi-automatic metal ceiling tile making machine:

Hydraulic Decoiler -- Precision Straightener - Punch Press - Feeder - Notching And Shearing Press (corner cut) - Feeder - 2nd Precision Straightener

4/ Accessories of Metal Ceiling Tile Production Line

Key metal ceiling tile production line accessories

1)Metal ceiling tile bending machine for metal ceiling tile making machine

The metal ceiling tile bending machine is a crucial component in a metal ceiling tile production line. Its primary function is to press and form the four corners of the metal sheet.

By changing different dies, the metal ceiling tile bending machine can produce a variety of metal ceiling tile types, such as clip in ceiling tile, lay in T24 ceiling tile, and lay in T15 ceiling tile.

The metal ceiling tile bending machine used by KINGREAL CEILING MACHINERY for the 600x600mm metal ceiling tile production line is typically 140 tons, while the metal ceiling tile bending machine used for the 600x1200mm metal ceiling tile making machine is 230 tons.

Both metal ceiling tile bending machines are equipped with cooling fans to prevent overheating. Metal ceiling tile bending machines of varying tonnages can meet the needs of varying thicknesses and materials, ensuring the quality and strength of the finished product.

The main function of a metal ceiling notching and shearing press machine(corner cut) is to remove the four corners of metal sheets and cut them according to the customer's specific specifications.

The metal ceiling notching and shearing press machine(corner cut) KINGREAL CEILING MACHINERY configures for metal ceiling tile making machines are typically 60 tons, compared to the standard 40-ton press in the industry.

Higher-tonnage metal ceiling notching and shearing press machine(corner cut) provide greater shear force, improving production efficiency and ensuring cutting accuracy. The metal ceiling notching and shearing press machine(corner cut) are also equipped with cooling fans to ensure stability and safety.

3) Molds for metal ceiling tile making machine

Molds are an essential component of metal ceiling tile making machines and are primarily divided into forming die, perforation die, and angle cutting die.

KINGREAL CEILING MACHINERY offers these molds with various hole and plate shapes to meet diverse metal ceiling tile production requirements.

High-quality molds ensure precision and consistency in the finished product, enhancing the overall quality of the metal ceiling tile.

Optional accessories about metal ceiling tile production line

To further enhance the automation level of the metal ceiling tile making machine, a variety of optional accessories are available to increase production efficiency and reduce labor costs.

1) Acoustic fleece sticking machine for metal ceiling tile production line

Metal ceiling tile making machines can be equipped with a acoustic fleece sticking machine to apply fleece to various metal materials, such as aluminum and steel.

The acoustic fleece sticking machine operates in three steps: a fleece sticking section, a drying section, and an air-fan cooling section.

This acoustic fleece sticking machine seamlessly integrates with metal ceiling tile making machines for fully automated production.

The acoustic fleece sticking machine not only enhances the aesthetics of the metal ceiling tile but also provides excellent sound absorption.

2) Metal sheet cleaning machine for metal ceiling tile production line

A metal sheet cleaning machine is another optional accessory for metal ceiling tile making machines. Its functions include a cleaning section (brush, water tank, drain pipe, etc.), a drying section (drying oven), and an oiling section (optional oil tank).

Based on customer production requirements, the metal sheet cleaning machine can be fully customized to meet specific requirements, such as thickness, width, and washing speed. The metal sheet cleaning machine cleans both sides of the metal ceiling tile, maintaining a clean surface and ensuring high-quality finished products.

5/ Perfectly Compatible with Various Metal Ceiling Tile Production Lines

These precision components can be seamlessly integrated with various metal ceiling tile making machines to meet individual customer needs. KINGREAL CEILING MACHINERY provides customized manufacturing solutions, including:

Fully-automatic metal ceiling tile production line,

Semi-automatic metal ceiling tile production line,

300x300mm metal ceiling tile production line,

600x600mm metal ceiling tile production line,

600x1200mm metal ceiling tile production line,

Clip in metal ceiling tile production line,

Lay in metal ceiling tile production line

......

6/ KINGREAL CEILING MACHINERY Metal Ceiling Tile Making Machine Manufacturing

During the manufacturing process of our metal ceiling tile making machines, KINGREAL CEILING MACHINERY rigorously controls every component (acoustic fleece sticking machine, metal sheet cleaning machine, metal ceiling tile bending machine, molds, metal ceiling notching and shearing press machine, etc.) to ensure high quality.

The manufacturing team conducts multiple inspections throughout the production process to guarantee metal ceiling tile making machine quality and on-time delivery. This rigorous approach has earned KINGREAL CEILING MACHINERY metal ceiling tile making machines a strong reputation in the industry.

7/ Project Case - Metal Ceiling Tile Making Machine

KINGREAL CEILING MACHINERY acoustic fleece sticking machine, metal sheet cleaning machine, metal ceiling tile bending machine, metal ceiling notching and shearing press machine(corner cut) and other components are available for sale separately.

KINGREAL CEILING MACHINERY has also shipped these components to countries including Saudi Arabia, Russia, Turkey, Brazil, Turkmenistan, and Greece. With over two decades of experience, KINGREAL CEILING MACHINERY is able to provide high-quality metal ceiling tile making machines and accessories to customers worldwide, along with comprehensive after-sales services, including machine installation, operator training, and repairs.

Through continuous technological innovation and superior customer service, KINGREAL CEILING MACHINERY is committed to becoming a leader in the global metal ceiling tile making machine industry, helping customers improve production efficiency and reduce operating costs, thereby achieving greater market competitiveness.

Get the latest price? We'll respond as soon as possible(within 12 hours)