5 Things to Consider When Buying Aluminum Ceiling Tile Making Machine

2025-10-03 17:00

Aluminum ceiling tile making machines are specialized for producing metal ceiling tiles. Utilizing galvanized iron coils, aluminum coils, and roll-coated coils as raw materials, metal ceiling tile making machine can accurately generate several sizes like 300x300mm, 600x600mm, and 1200x600mm, as along with several metal ceiling tile types, including lay-in ceilings (T24, T15), lay-on ceilings, clip-in ceilings, and tegular ceilings. Favorite by many businesses, aluminum ceiling tile making machines have become essential and crucial tools in the building sector as metal ceiling tile making machine effectively produce high-precision metal ceiling tiles. But selecting one among the great diversity of aluminum ceiling tile making machines on the market presents businesses with great problems. Five main considerations must be kept in mind when choosing the metal ceiling tile making machine that most closely fits their production requirements: production capacity, machine quality, technological support, cost, equipment mobility, and scalability. The following will provide a detailed analysis of each.

1. Evaluating the Production Capacity of Metal Ceiling Tile Making Machine

Before purchasing an aluminum ceiling tile making machine, companies must clearly define their desired production capacity. This requires a comprehensive assessment based on multiple factors, including business scale, order volume, and market expansion plans. This ensures that the selected metal ceiling tile making machine fully meets the company's production needs, avoiding situations where insufficient production capacity leads to order delays, or excess production capacity leads to idle aluminum ceiling tile making machine.

Specifically, evaluating production capacity begins with determining a daily production target. This daily production volume directly determines the production speed and operating hours of the metal ceiling tile making machine. As a professional aluminum ceiling tile making machine manufacturer, KINGREAL CEILING MACHINERY will tailor-make a metal ceiling tile making machine based on the customer's specific production capacity needs. For high-volume production that requires the aluminum ceiling tile making machine to operate for extended periods, KINGREAL CEILING MACHINERY engineers will specifically equip the metal ceiling tile making machine with a cooling fan. This cooling device primarily dissipates heat from the two core components: notching and shearing press and auto bending forming press. They perform critical processing tasks in the operation of aluminum ceiling tile making machines. Prolonged, high-speed operation easily generates significant heat. Overheating components might result if this heat is not quickly dispersed, which would impair not just component performance but perhaps cause the metal ceiling tile making machine to fail and hence delay production. These two main components have cooling fans by KINGREAL CEILING MACHINERY, therefore solving the problem of overheating. This ensures stable, continuous, and efficient operation of the aluminum ceiling tile making machine, ensuring smooth progress for customers' production tasks.

2. Strict Quality Control of Aluminum Ceiling Tile Making Machine

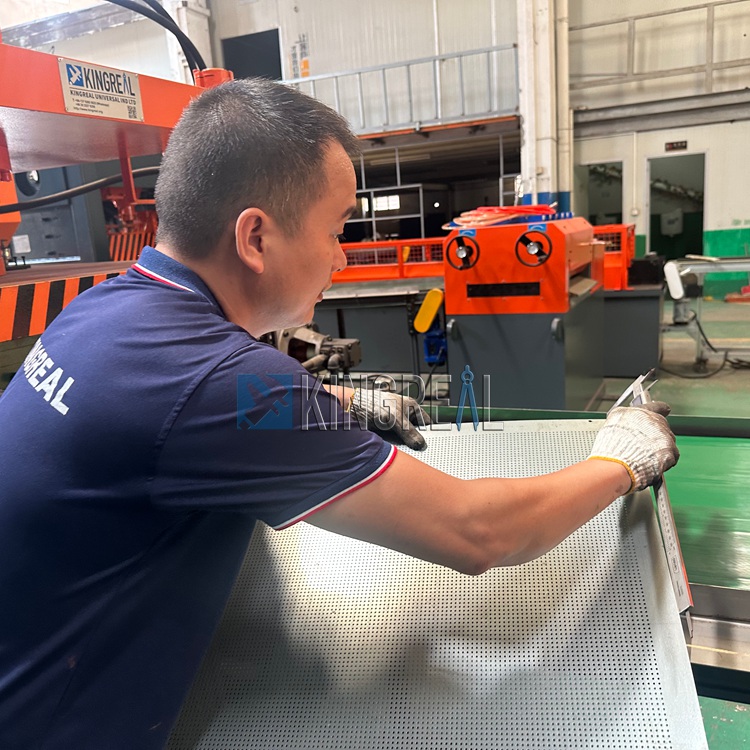

Therefore, when selecting a metal ceiling tile making machine, companies must rigorously control machine quality and conduct a comprehensive evaluation from multiple perspectives. The materials used in aluminum ceiling tile making machine manufacturing are a key factor in assessing quality. KINGREAL CEILING MACHINERY maintains extremely high standards and extensive experience in quality control for metal ceiling tile making machines. KINGREAL CEILING MACHINERY cordially welcomes on-site plant tours to give customers a clear and complete knowledge of the quality of aluminum ceiling tile making machine. Customers can personally witness the metal ceiling tile making machine in operation during the inspection, therefore grasping its operating stability and productivity. Experiencing its simplicity of use and flexibility, they may also manually operate the aluminum ceiling tile making machine. Moreover, customers can personally examine the metal ceiling panels made by the metal ceiling tile making machine, hence confirming the quality of the finished product in dimensional precision, surface flatness, and edge finish terms of reference. Furthermore, customers can visit KINGREAL CEILING MACHINERY raw material and machine manufacturing workshops. KINGREAL CEILING MACHINERY staff will enthusiastically and in detail explain the high-quality raw materials used in the aluminum ceiling tile making machine and the rigorous production process from raw material processing and component assembly to finished product testing. This on-site visit allows customers to gain a comprehensive and in-depth understanding of the quality advantages of KINGREAL CEILING MACHINERY metal ceiling tile making machine. Furthermore, with proper use and regular maintenance, KINGREAL CEILING MACHINERY aluminum ceiling tile making machines can have a service life of over 10 or even 20 years.

3. Emphasize Technical Support for Metal Ceiling Tile Making Machine

When selecting an aluminum ceiling tile making machine, companies must prioritize whether the supplier provides comprehensive and efficient technical support. KINGREAL CEILING MACHINERY offers customers comprehensive and efficient technical support services. During the installation phase of the metal ceiling tile making machine, KINGREAL CEILING MACHINERY dispatches professional technicians to the customer's site to oversee the aluminum ceiling tile making machine installation and commissioning, ensuring smooth commissioning. Regarding operator training, KINGREAL CEILING MACHINERY tailors training programs to the customer's needs. Through a combination of theoretical explanations and practical guidance, operators quickly master the metal ceiling tile making machine's operation and routine maintenance techniques. If a customer encounters a malfunction or wear or breakage of an aluminum ceiling tile making machine, simply contact KINGREAL CEILING MACHINERY, and their professional technical team will respond promptly, providing repair services and timely supply of required spare parts. KINGREAL CEILING MACHINERY is always customer-centric and committed to resolving issues as quickly as possible, minimizing metal ceiling tile making machine downtime and ensuring normal production, preventing equipment issues from impacting production schedules.

4. Calculating the Cost of Metal Ceiling Tile Making Machine

When selecting an aluminum ceiling tile making machine, companies should not only focus on the purchase price but also comprehensively consider the metal ceiling tile making machine's maintenance, repair, and energy costs. This comprehensive calculation will help them select the most cost-effective aluminum ceiling tile making machine that maximizes long-term cost-effectiveness. Some companies, when purchasing metal ceiling tile making machine, blindly pursue low purchase costs while ignoring the subsequent operational costs of the machine, ultimately resulting in losses that outweigh the benefits. For example, some companies purchase inexpensive aluminum ceiling tile making machines, only to find that the machines frequently malfunction and require constant repairs. The resulting maintenance and repair costs are high, sometimes accounting for nearly one-third of the purchase price. This ultimately increases the company's overall costs.

Moreover, businesses must thoroughly assess the cost-effectiveness of metal ceiling tile making machine from a long-term operating point of view. Purchase price, maintenance cost, repair cost, and energy use should all be considered when estimating expenses. Furthermore, factors such as the aluminum ceiling tile making machine's efficiency, finished product quality, and service life should be considered to analyze the potential benefits to the company over its entire life-cycle.

5. Focus on the Flexibility and Scalability of Metal Ceiling Tile Making Machine

When purchasing aluminum ceiling tile making machines, companies should also consider the equipment's flexibility and scalability to ensure that the metal ceiling tile making machine can adapt to changing market demands and the company's future growth needs. KINGREAL CEILING MACHINERY aluminum ceiling tile making machine can process a variety of metal materials, including GI steel and aluminum, fully meeting customers' needs for producing metal ceiling tiles of varying materials. Furthermore, by replacing different molds, KINGREAL CEILING MACHINERY metal ceiling tile making machine can produce metal ceiling tiles with varying parameters on a single machine, eliminating the need to purchase separate aluminum ceiling tile making machines for different products. This significantly improves equipment utilization and reduces production costs.

KINGREAL CEILING MACHINERY semi-automatic metal ceiling tile making machine is designed to meet the needs of business growth, offering excellent scalability. To meet the needs of expanding production, businesses can upgrade their existing semi-automatic metal ceiling tile making machine to a fully automated one by adding components such as a tiles flipping machine, an automatic tile feeding machine, and an automatic bending forming machine. This upgrade not only significantly improves production efficiency to meet the needs of expanding production, but also effectively reduces investment costs by avoiding the waste associated with purchasing a complete new aluminum ceiling tile making machine, providing strong support for the company's long-term development.

Get the latest price? We'll respond as soon as possible(within 12 hours)