The Importance of Steel Perforated Making Machine

2025-09-25 17:00

The steel perforated making machine mainly produces perforated plates or perforated coils that meet different requirements through a series of continuous processes such as uncoiling, leveling, punching, shearing or winding of metal coils in sequence. These metal products processed by the perforated metal machine can be further processed and manufactured into various shaped components and finished products, which are widely used in multiple key industries such as automotive manufacturing, home appliance manufacturing, and electronic equipment manufacturing, providing indispensable basic material support for the production of products in various industries.

With the rapid advancement of technology and the continuous acceleration of the pace of social development, all industries have also ushered in a period of vigorous development opportunities. In such a market environment, the demand for steel perforated making machines in all industries has also increased significantly accordingly. The quality and performance of perforated metal machines directly affect the production efficiency and product quality of downstream industries.

The Importance of Steel Perforated Making Machine

(1) Fully automatic perforated metal machine

The automatic steel perforated making machine has replaced the previous simple processing tools and integrated a series of precision components such as decoiler, leveling machine, and metal punching machine. Staff only need to accurately input production parameters such as punching hole diameter, hole spacing, and processing speed on the PLC control panel. The perforated metal machine will then automatically operate according to the preset instructions, completing the entire process from uncoiling the metal coil to the final product processing.

Throughout the entire production process, the steel perforated making machine can achieve continuous processing without interruption, eliminating the need for frequent manual intervention and minimizing human input to the greatest extent. Meanwhile, automated operation avoids problems such as fatigue and errors that may occur during manual operation, significantly enhancing production efficiency.

(2) High precision perforated metal machine

As a professional manufacturer of steel perforated making machine, KINGREAL CEILING MACHINERY will customize high-precision punching dies based on the detailed drawings provided by customers. At the same time, it will pair the perforated metal machine with high-performance metal punching machines to carry out precise punching processing on the surface of metal coils.

KINGREAL CEILING MACHINERY steel perforated making machine can control the processing accuracy error within ±0.1mm. Such a high-precision processing level can fully meet the precision requirements of most industries for metal punching products. High-precision punching processing not only ensures the dimensional consistency of each perforated product, guarantees the smoothness of subsequent product assembly, but also significantly reduces the product scrap rate caused by insufficient precision, saves production costs for enterprises, and enhances the competitiveness of products in the market.

(3) High flexibility perforated metal machine

Different industries and products have varying requirements for the hole type and diameter of punching. The steel perforated making machine, with its high flexibility, can easily meet such diverse production demands. KINGREAL CEILING MACHINERY has an in-depth understanding of market demands and is capable of providing customers with punching dies of various hole types and diameters. Common hole types include square, round, hexagon, round end slot, etc. It almost covers the mainstream punching hole types currently available in the market.

Not only that, KINGREAL CEILING MACHINERY steel perforated making machines also have a significant advantage in the processing range of hole diameters. They can support a minimum punching hole diameter of 1.0mm, which can meet the processing requirements of fine hole diameter punching products in industries such as electronic devices. More importantly, the flexibility of the perforated metal machine is reflected in the convenience of die replacement. Staff only need to replace the corresponding punching dies according to the standard procedures, without making large-scale adjustments to the entire steel perforated making machine, to achieve the production of metal punched plates with different hole types and diameters with one perforated metal machine.

Application of Perforated Metal Machine

The requirements for punching processes vary across different industries and projects. Some need to rewind the perforated metal coils for subsequent processing or transportation, some require them to be cut into plates of specific lengths for direct use, and others have specific processing requirements for particular products (such as perforated ceiling tiles). Based on this, KINGREAL CEILING MACHINERY, with its rich industry experience and strong technical R&D capabilities, has designed three distinctive machine manufacturing solutions for perforated metal machines according to the different demands of customers for punching processes and the specific circumstances of projects. These solutions are the coil to coil perforation line, metal sheet perforated machine, and the metal ceiling tile perforation line. Each solution has its unique structural design and applicable scenarios, providing customers with a comprehensive punching processing solution.

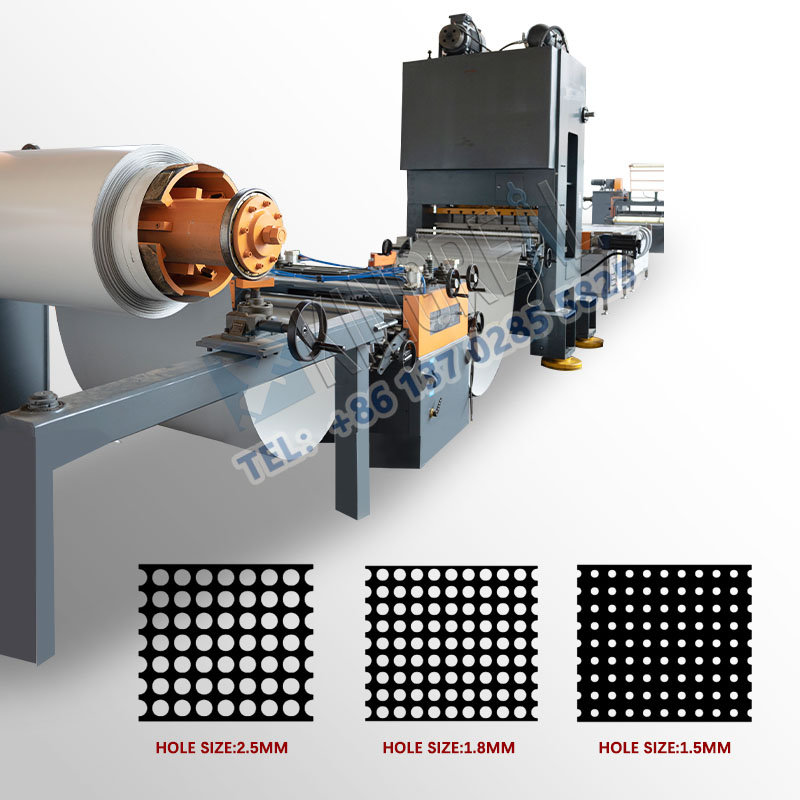

| (1) Coil to coil perforation line In some production scenarios, customers need to transport the punched metal coils over long distances or carry out subsequent secondary processing (such as bending, welding, etc.) on them. KINGREAL CEILING MACHINERY has specially equipped this steel perforated making machine with a recoiler, so this production line is also called a coil to coil perforation line. After the metal coil is punched in the steel perforated making machine, there is no need for shearing treatment. It can be directly rewound by the recoiler to re-wind the punched metal coil into a neat roll shape. This roll-shaped finished product form not only significantly reduces the space occupied during transportation and lowers transportation costs, but also effectively prevents deformation and damage of metal coils during transportation, ensuring the quality of product transportation. Meanwhile, the rolled perforated metal coil is also more convenient for subsequent secondary processing. Staff can cut the required length of material from the rolled coil at any time according to the needs of secondary processing for processing. Work process: Decoiler - Leveling Machine - Metal Punching Machine - Recoiler Application: Perforated baffle ceilings, Bread Trays... |  |

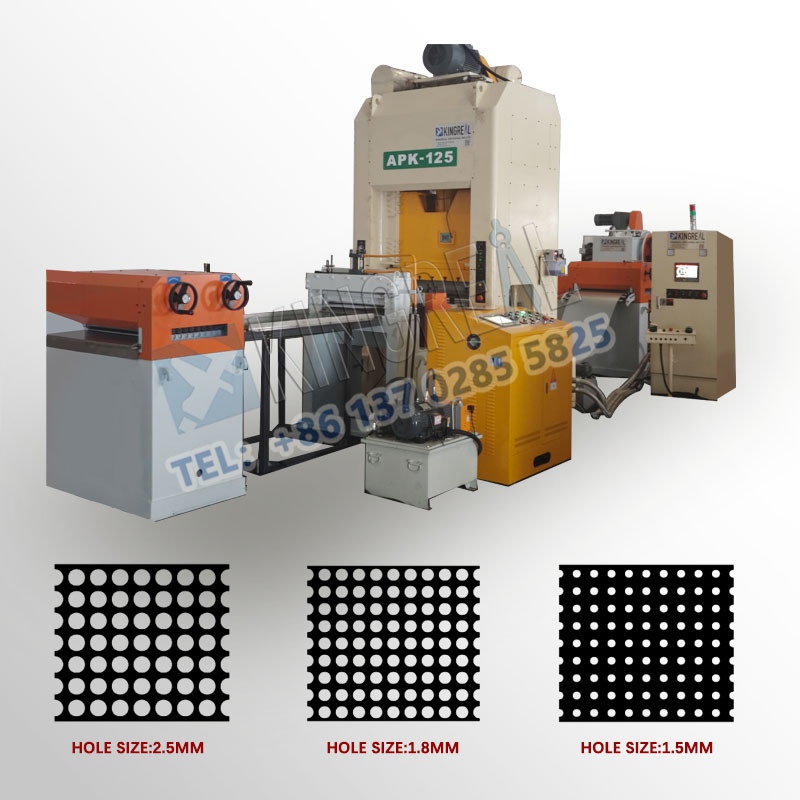

| (2) Metal sheet perforated machine In many industries, what customers need are perforated metal sheets of specific lengths for direct use in product assembly or production. KINGREAL CEILING MACHINERY has equipped this perforated metal machine with a high-precision shearing station, so this production line is called a metal sheet perforated machine. After the metal coils complete the processes of uncoiling, leveling and punching in the steel perforated making machine, they will be conveyed to the shearing station. The shearing station will precisely cut the punched metal coils according to the length parameters preset by the customer, and produce punched metal plates of uniform length that meet the customer's requirements. Thanks to the adoption of advanced cutting technology and precise control systems, the cutting accuracy of the shearing station can match that of the metal sheet perforated machine, ensuring that the punched plates after cutting not only meet the requirements in terms of hole diameter and hole shape, but also have highly accurate length dimensions. This precisely cut perforated sheet does not require subsequent cutting and processing by the customer and can be directly put into use, significantly shortening the customer's production cycle and improving production efficiency. Work process: Decoiler - Leveling Machine - Metal Punching Machine - Cutting Station Application: Perforated wall panels, Perforated mufflers... |  |

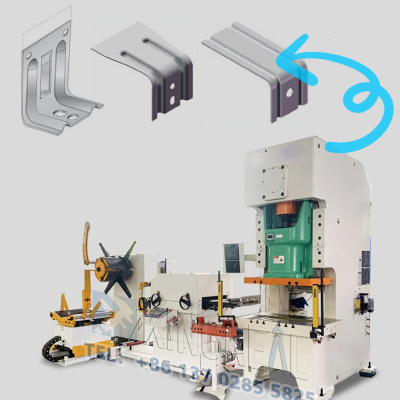

(3) Metal ceiling tile perforation line To meet the production demands of the perforated ceiling tile, KINGREAL CEILING MACHINERY has specially designed a metal ceiling tile perforation line. This metal ceiling tile perforation line can be perfectly matched with the metal ceiling tile production line and can produce perforated ceilings of different sizes and types. Common perforated ceiling sizes include 300x300mm, 600x600mm, 1200x600mm, etc. The types cover various styles such as clip in ceiling tile, lay in ceiling tile, tegular ceiling tile, etc., which can meet the metal ceiling tile decoration requirements of different architectural styles and different usage scenarios. Workflow: Uncoiling → Leveling→ Perforated Plate → Hydraulic Notching & Shearing Machine → 2nd Leveling → Products Out Put or Other Processing Application: Perforated ceiling tiles |  |

Get the latest price? We'll respond as soon as possible(within 12 hours)