Comprehensive Guide to Sheet Metal Straightener for Sheet Metal Processing

2025-10-31 17:00

Video About Sheet Metal Straightener

1/What is a Sheet Metal Straightener?

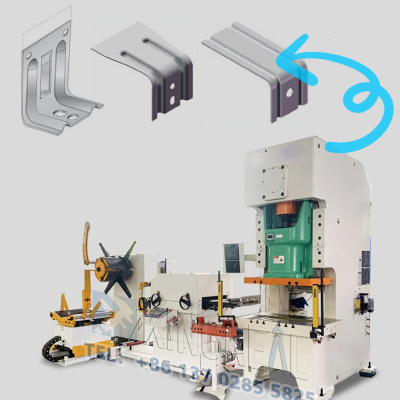

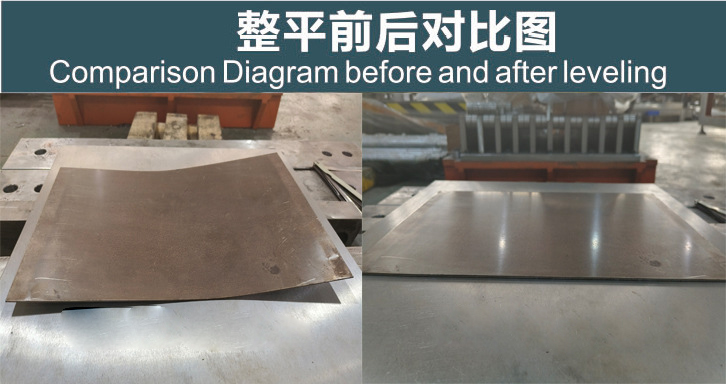

A sheet metal straightener is a specialized device used to level the surfaces of various metal materials, including sheets, perforated metal sheets, metal rods, and metal parts. This sheet metal flattening machine’s main function is to eliminate internal stress and correct any flatness defects. In any industry, sheet metal straighteners are typically used to level metal surfaces before application or processing to ensure flatness, thereby improving the effectiveness and quality of subsequent processing.

2/Working Principle of Sheet Metal Flattening Machine

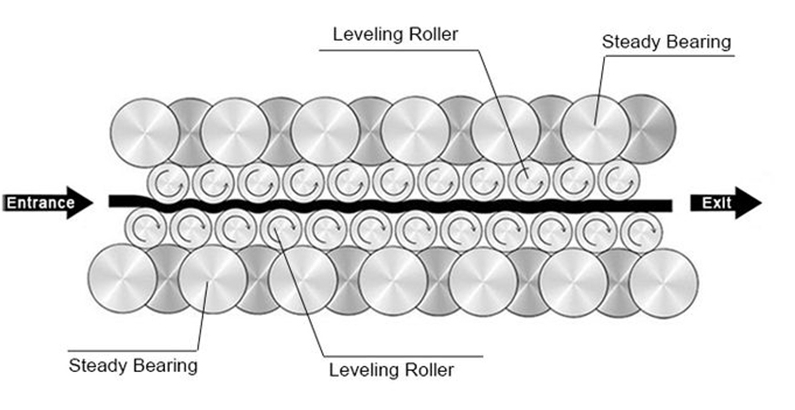

The basic structure of a sheet metal straightener includes an infeed roller, an outlet roller, a leveling roller, and a support system. The operator places the workpiece to be leveled on the infeed roller, and the sheet metal flattening machine automatically transports the workpiece into the screed. The upper and lower support structures of the leveling rollers ensure the incompressibility of the rollers, thus reducing the gap between them.

The sheet metal straightener utilizes the "Bauschinger effect" of the material to repeatedly bend the sheet metal, gradually reducing the intensity of the alternating bending. The quantity of alternating bends grows along with the quantity of leveling rollers, therefore changing several original curvatures into a single curvature and eventually attaining flatness. This procedure guarantees the quality of the finished product by removing internal stress as well as improving the flatness of the material. Through the discharge port, the leveled workpiece is carried and then hand-stacked.

3/KINGREAL CEILING MACHINERY Sheet Metal Straightener Solutions

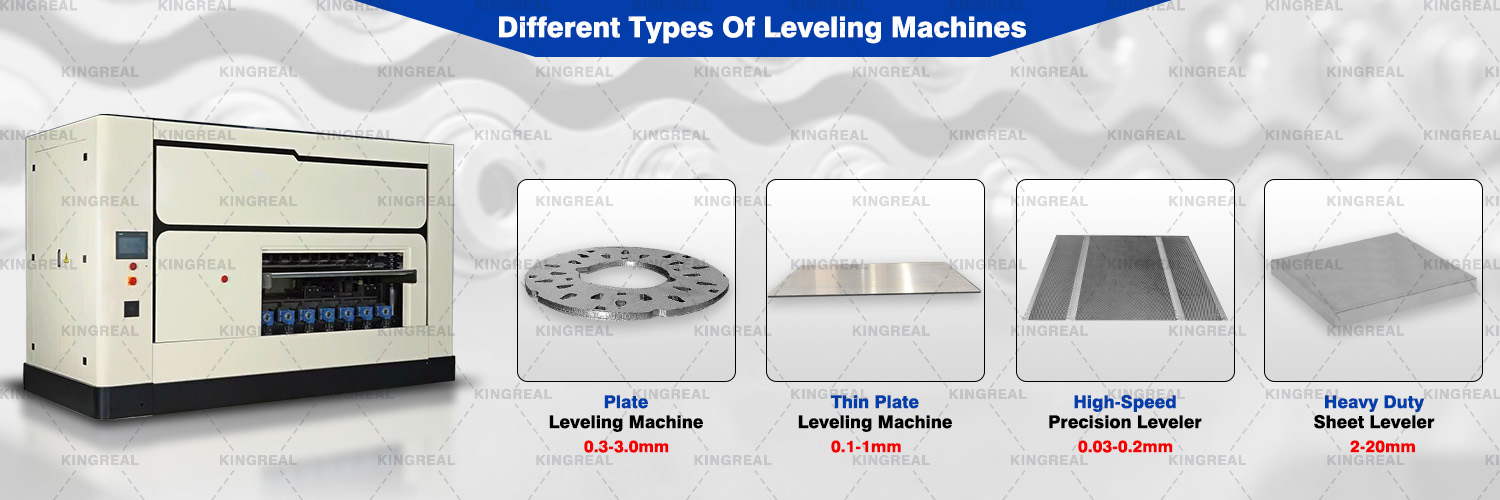

KINGREAL CEILING MACHINERY, as a professional manufacturer of sheet metal flattening machines, offers a variety of types of leveling machines, fully customized to meet customer project needs. Different types of sheet metal straighteners can handle different thicknesses, materials, and leveling effects, meeting the needs of various industries and applications. Below are some of KINGREAL CEILING MACHINERY featured sheet metal flattening machines:

●Sheet Metal Flattening Machine

These sheet metal flattening machines can handle common materials from 0.3-3mm, applying strong leveling force to effectively eliminate flatness issues. Industries with very strict demands for structural stability and accuracy, including automotive, aerospace, and luxury manufacturing, make extensive use of these sheet metal flattening machines.

●Thin Sheet Metal Flattening Machine

KINGREAL CEILING MACHINERY thin sheet metal straighteners are designed to handle thin materials from 0.1-1mm. Thinner metal sheets are best suited for these thin sheet metal flattening machines, which guarantee a smooth and flat surface perfect for production operations including stamping, forming, and cutting. Often found in the automobile and electronics sectors, these thin sheet metal straighteners fulfill the exacting standards for accuracy and visual appeal demanded by the market.

●High-Speed Precision Sheet Metal Straightener

KINGREAL CEILING MACHINERY high-speed precision sheet metal straighteners focus on processing ultra-thin, ultra-flexible sheets of 0.03-0.2mm, suitable for microelectronics, precision film materials, and other fields. Designed to provide fast and precise leveling results, these high-speed precision sheet metal flattening machines are particularly suitable for high-volume production environments.

●Heavy Duty Sheet Metal Flattening Machine

KINGREAL CEILING MACHINERY heavy duty sheet metal straighteners can handle sheets up to 20mm thick. For customers requiring even thicker materials, leveling needs of 30mm or even 60mm can be met. These heavy duty sheet metal flattening machines are designed for the hardest materials and most demanding applications, widely used in shipbuilding, construction, and other industries, providing powerful leveling performance.

4/Advantages of Sheet Metal Straightener

Sheet metal flattening machines offer several advantages in modern production, including:

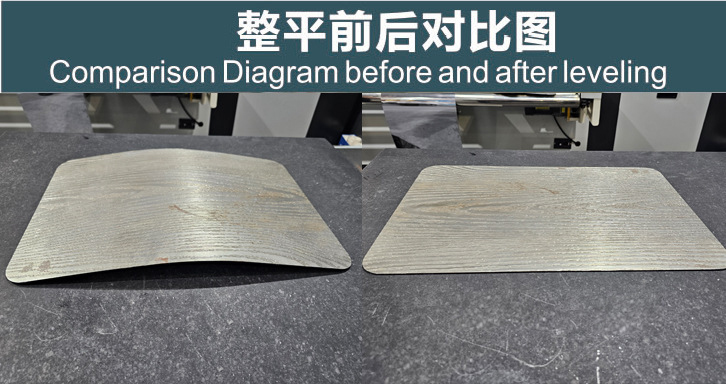

4.1 Perfect Flatness

Sheet metal straighteners remove even the finest bends in the sheet metal, achieving perfect flatness. This not only makes the ultimate product's aesthetics and quality much better but also sets a strong base for future treatment. Flat metal sheets guarantee greater assembly outcomes and extended service life whether utilized in electronics, building structures, or automotive production.

4.2 High-Efficiency Production

Sheet metal flattening machines, with their automation and rapid operation, accelerate production processes, reduce labor costs, and improve overall production efficiency. Modern sheet metal straighteners are typically equipped with intelligent control systems that automatically adjust working parameters according to different materials and thicknesses, ensuring optimal results every time.

4.3 Flexible Applications

Sheet metal flattening machines can handle sheets of varying thicknesses and sizes, offering strong adaptability and wide application across multiple industries. Whether it's thin sheets, thick sheets, or special materials, levelers can meet different leveling needs by adjusting working parameters. This flexibility allows companies to quickly adapt to market changes when facing diverse production demands.

4.4 Durability

Sheet metal straighteners feature a robust structural design, resulting in a long service life and low maintenance costs, saving companies long-term operating expenses. High-quality materials and excellent craftsmanship enable levelers to withstand prolonged high-intensity work without malfunction or performance degradation. Regular maintenance and upkeep further extend the sheet metal flattening machine's lifespan.

5/Applications of Sheet Metal Straightener

5.1 Sheet metal flattening machine in automotive industry

In automotive manufacturing, sheet metal straighteners are used to level sheet metal for body, chassis components, and structural parts, ensuring the precision and reliability of these critical components. High-quality metal materials not only improve vehicle safety but also enhance its appearance.

5.2 Sheet metal straightener in construction industry

In the construction industry, sheet metal straighteners are used to level structural components, exterior walls, and decorative panels to ensure the quality and aesthetics of building materials. Smooth metal materials can better integrate with other materials, improving the overall performance of the building.

5.3 Sheet metal straightener in manufacturing industry

From household appliances to industrial equipment, sheet metal flattening machines can easily handle a variety of materials, ensuring the quality and functionality of finished products. Whether for small-batch or large-scale production in manufacturing, sheet metal straighteners provide efficient solutions.

5.4 Sheet metal straightener in electrical industry

In the electrical industry, sheet metal flattening machines level sheet metal for housings, panels, and other electrical components, ensuring the stability and safety of electrical equipment. Smooth housings effectively protect internal components and extend the sheet metal flattening machine's lifespan.

5.5 Sheet metal straightener in electronics industry

In the electronics industry, sheet metal straighteners are also used to process the metal parts of electronic components, ensuring their reliable performance during assembly and use. With the continuous development of electronic products, the application of sheet metal flattening machines is becoming increasingly widespread.

Get the latest price? We'll respond as soon as possible(within 12 hours)