Understanding Metal Perforated Making Machine Process

2025-10-07 17:00

Metal perforated making machines can perform multiple processes on metal coils, including uncoiling, flattening, punching, rewinding, and cutting. These perforated metal machines can produce a wide variety of hole patterns on the surface of metal coils, including round, oblong, square, triangular, diamond, hexagonal, and cross-shaped holes. This flexibility and versatility have led to their widespread application in industries such as construction and automotive. This article details the process flow and design key points of metal perforated making machines, hoping to provide relevant information. For more information about perforated metal machines, please feel free to contact KINGREAL CEILING MACHINERY!

01/ Introduction to Metal Perforated Making Machine

Perforated metal machines, with their high punching accuracy, fast punching speed, and fully automated operation, have become essential equipment in modern production. KINGREAL CEILING MACHINERY equips metal perforated making machines with metal punching machines of varying tonnages based on specific customer requirements, such as hole pattern, material width, material type, and thickness. This customized service ensures that the perforated metal machines can meet customers' punching needs for various hole diameters, including small and large. Depending on the project and production process requirements, common metal perforated making machines include three types: coil to coil perforation line, metal sheet perforated machine, and metal ceiling tile perforation line. These perforated metal machines are widely used in various fields, helping customers efficiently complete metal processing.

02/ Working Process of Metal Perforated Making Machine

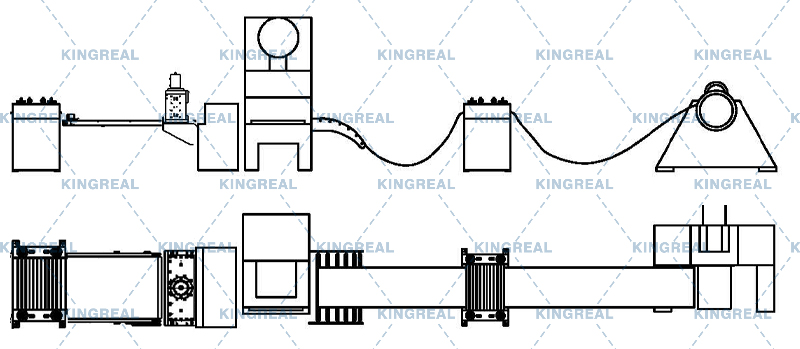

Decoiler - Leveling Machine - Metal Punching Machine - Recoiler/Cutting Station

03/ Key Design Considerations for Perforated Metal Machine

1. Metal punching machine tonnage for perforated metal machine

The metal punching machine tonnage of a metal perforated making machine depends on multiple parameters, including hole shape, material width, material type, and thickness. Metal punching machines of different tonnages also have different strokes. KINGREAL CEILING MACHINERY has a specialized formula to calculate the required metal punching machine tonnage to ensure sufficient force to punch the desired hole shape. KINGREAL CEILING MACHINERY engineers will provide reasonable metal punching machine tonnage recommendations based on the customer's actual production needs to avoid wasted resources or inability to meet production requirements.

2. Punching die for perforated metal machine

The customized design of the punching die is a critical component of a metal perforated making machine. KINGREAL CEILING MACHINERY engineers will design the die based on the customer's drawings and will confirm perforation parameters, such as hole diameter and spacing, with the customer on multiple occasions. Notably, KINGREAL CEILING MACHINERY perforated metal machines can meet the needs of even small-diameter holes. KINGREAL CEILING MACHINERY engineers have previously provided small-diameter holes with diameters of 1.0mm and 1.5mm for customers in Morocco and Greece. The production of such small holes places high demands on the design and fabrication of the punching dies, including precision, wear resistance, and processing technology.

04/ Optional Configurations of Perforated Metal Machine

To maximize the production efficiency and automation level of the metal perforated making machine, KINGREAL CEILING MACHINERY engineers can configure the perforated metal machine with a variety of optional configurations, including:

1. Feeding trolley for perforated metal machine

The introduction of a feeding trolley significantly improves production efficiency. Simply place the coil on the feeding trolley, and it will automatically be transported to the decoiler, eliminating the need for manual handling. This not only reduces the operator's workload but also improves the overall efficiency of the metal perforated making machine.

2. Unloading trolley for perforated metal machine

After rewinding, the unloading trolley automatically transports the punched coil from the recoiler to a designated location, eliminating the safety hazards and inefficiencies associated with manual handling.

3. Metal sheet cleaning machine for perforated metal machine

During the punching process, the surface of the metal sheet may become contaminated with oil. The metal sheet cleaning machine cleans the surface of the punched sheet, ensuring that the finished sheet maintains its appearance and quality for subsequent use or sale. This feature not only improves production automation but also reduces cleanup work during subsequent processes, thereby increasing production efficiency.

The metal perforated making machine process is a systematic and complex process, encompassing every step from raw material preparation to final product shipment. Through efficient equipment configuration and precise design, the perforated metal machine can meet diverse customer needs and produce a wide range of hole shapes and diameters. KINGREAL CEILING MACHINERY expertise and customized services in metal perforated making machine manufacturing give it a strong competitive edge in the market. If you have any further questions about the perforated metal machine process or require more information, please feel free to contact KINGREAL CEILING MACHINERY.

Get the latest price? We'll respond as soon as possible(within 12 hours)