What is a furring channel machine used for?

2025-09-23 17:00

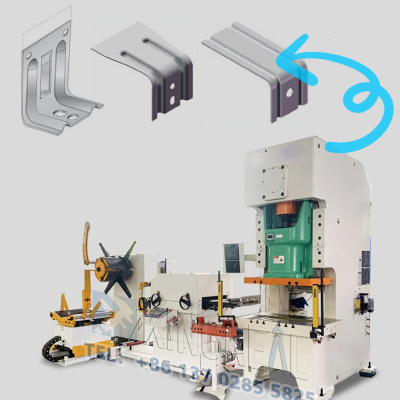

A furring channel machine, also known as a hat channel machine or omega channel machine, is a device specifically designed to manufacture furring channels. It typically uses galvanized steel (GI steel) as raw material to produce hat channels of varying specifications. These omega channels, along with profiles produced by main channel making machine and drywall wall angle profile machine, are used in suspended ceiling system installations, providing customers with a complete suspended ceiling system solution. This article will delve into the uses of a hat channel machine and its importance in building construction.

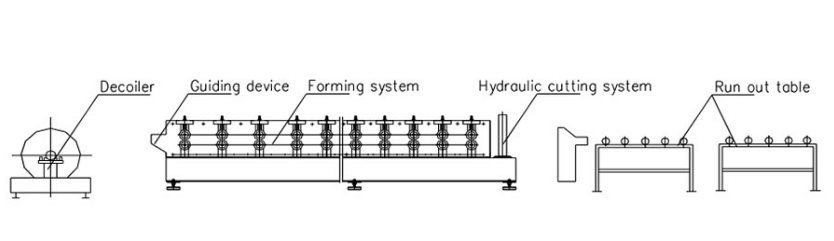

Workflow of Furring Channel Machine

Hydraulic Decoiler--Main Roll Forming Machine--Hydraulic Cutting Station--Product Table

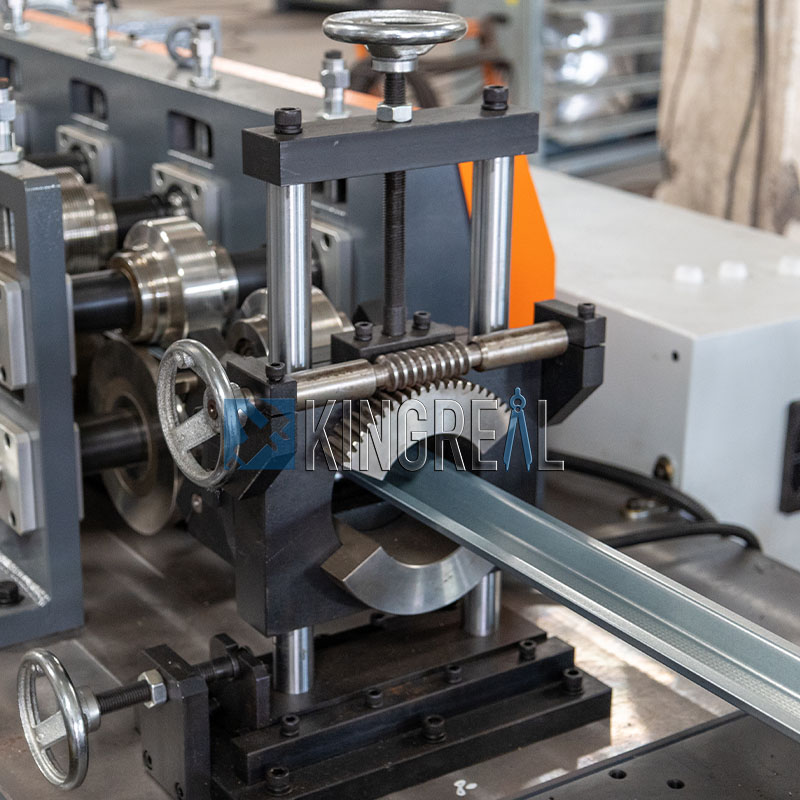

Parameters of Hat Channel Machine

Material: GI Strip

Material Thickness: 0.4-1.3mm

Production Speed: 120m/min

Function of Furring Channel Machine

1. High efficient hat channel machine

The furring channel machine boasts a maximum production speed of 120m/min, providing customers with extremely high throughput and enabling the rapid delivery of required profiles even under tight project deadlines. By flexibly adjusting the production speed on the PLC control panel, customers can adjust to actual production needs, ensuring maximum production efficiency.

The high production capacity of the hat channel machine enables construction companies to complete large-scale product production in a short period of time, reducing wait times and improving overall project progress.

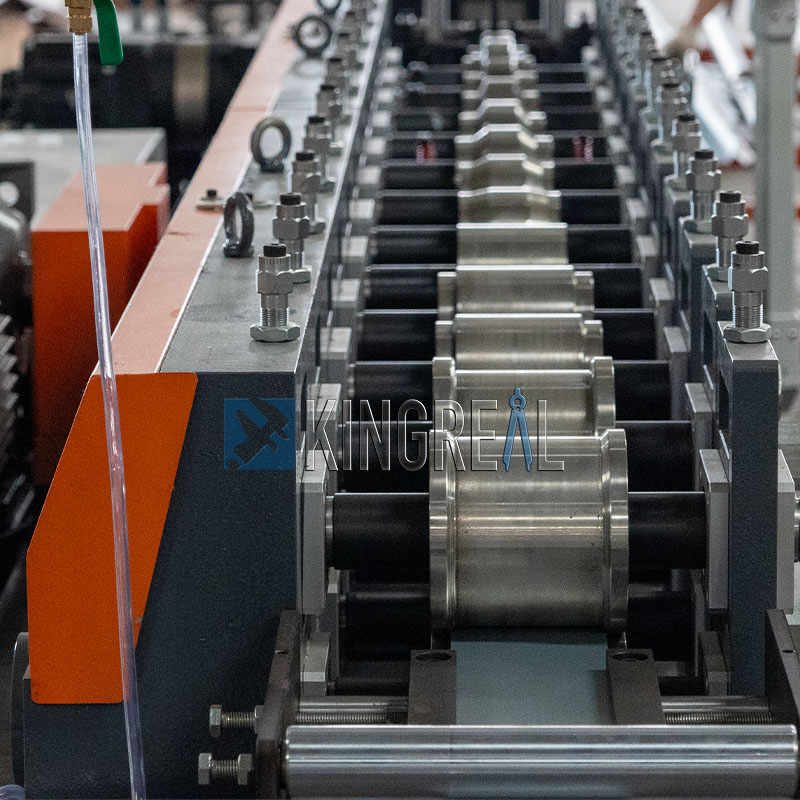

2. High precision furring channel machine

The hat channel machine produces finished products that meet high standards. Its shearing accuracy reaches ±1.0mm, and even minor deformation caused by material stress can be anticipated and compensated for. Furthermore, straightness deviation is less than 1%/m, and twist is less than 1.3%/m. These factors ensure a precise fit during installation, reducing subsequent adjustments and finishing work.

Precision production not only improves the quality of the finished product but also reduces rework and waste caused by defective products, enabling construction companies to use resources more efficiently.

3. High automated furring channel machine

Modern hat channel machines feature a highly automated design, incorporating multiple automated precision components, including the decoiler, main roll forming machine, cutting station, and discharge table. The operator simply enters production parameters, including production quantity, speed, and specifications, on the control panel, and the furring channel machine automatically begins operation. This level of automation significantly reduces labor costs and improves production efficiency.

Automated production not only reduces the risk of human error but also ensures stable performance over extended periods of operation. By reducing manual intervention, construction site safety is improved, allowing workers to focus on other important tasks.

4. Safe hat channel machine

Safety is a key consideration in the design of the furring channel machine. KINGREAL CEILING MACHINERY has equipped the hat channel machine with various safety features to ensure safe operation and meet the safety performance standards of several countries. During operation, a protective shield effectively prevents workers from accidentally contacting the forming rollers. After the furring channel machine stops, the cover can be opened for routine maintenance and cleaning, ensuring the long-term reliability of the hat channel machine.

5. Complete suspended ceiling system solution

The furring channel machine can produce hat channels of various specifications. By combining this furring channel machine with KINGREAL CEILING MACHINERY u channel making machine and drywall wall angle profile machine, it can be used in suspended ceiling systems to provide support and stability for suspended ceiling installation, improving overall production efficiency.

6. High cost-effective hat channel machine

Investing in a furring channel machine can bring significant cost benefits to construction companies. First, the hat channel machine's high efficiency and precision reduce raw material waste and maximize resource utilization. Second, automated production reduces labor costs, allowing companies greater flexibility in staffing. Furthermore, the versatility of the furring channel machine allows companies to meet various production needs with a single machine, reducing equipment investment costs.

By optimizing the production process and improving resource utilization, the hat channel machine helps companies improve overall economic efficiency and enhance their market competitiveness.

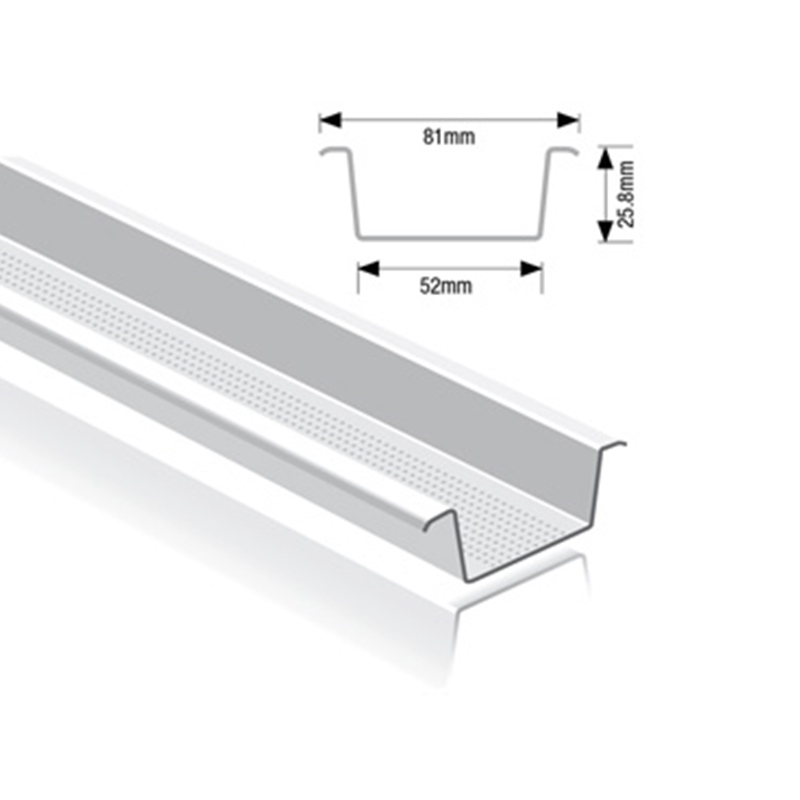

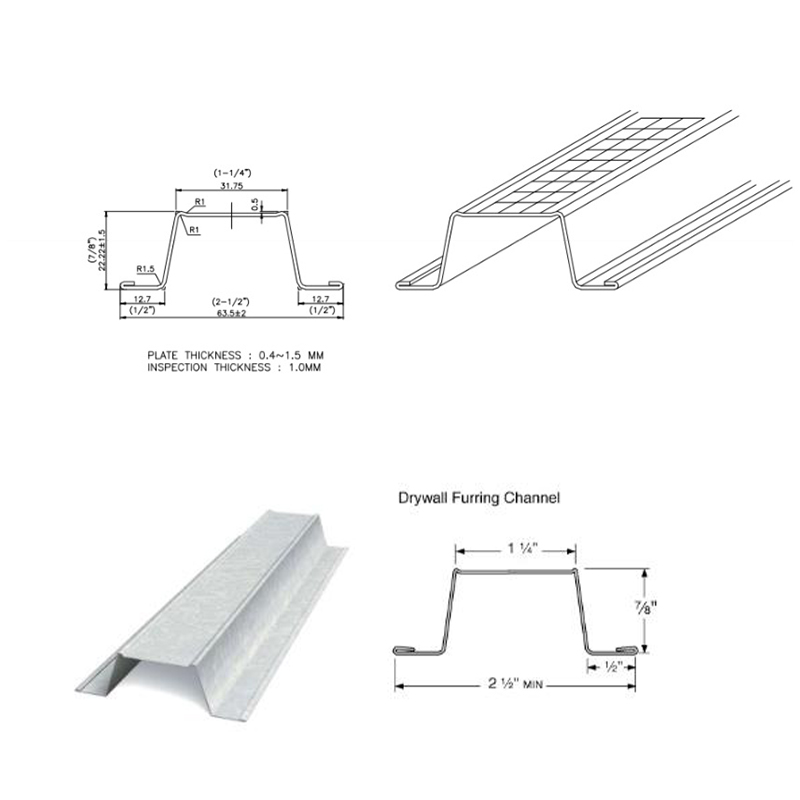

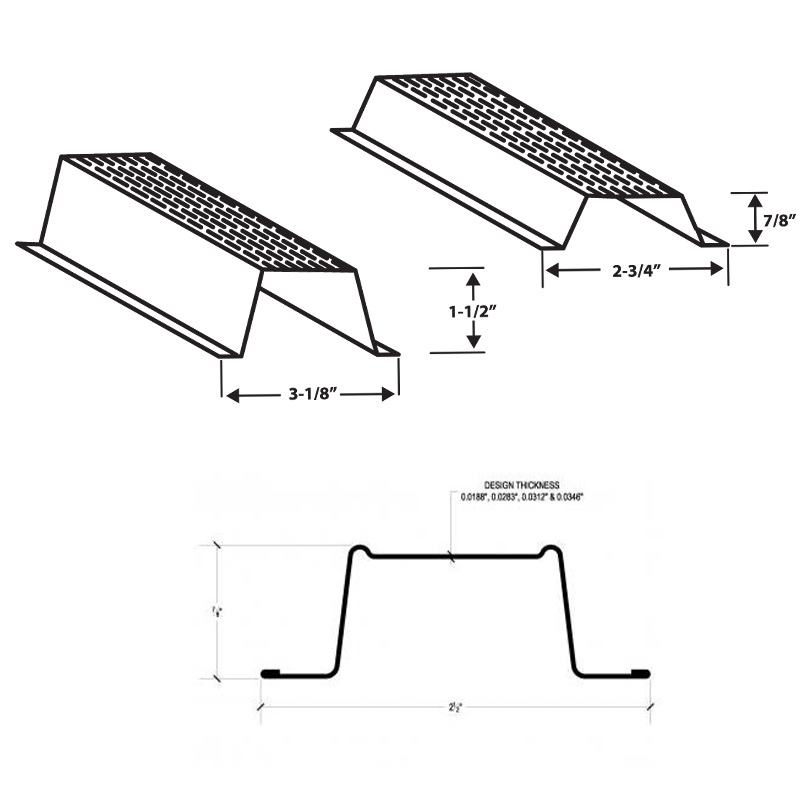

Introduction to Furring Channel Product

The hat channel produced by the furring channel machine is a metal frame component primarily used in the installation of suspended ceiling systems. As a key profile supporting suspended ceilings, it has the following main uses:

1. Surface Leveling

Furring channels are used for surface leveling, effectively smoothing uneven or irregular surfaces such as masonry and concrete walls and ceilings. By installing furring channels on these surfaces, construction workers can ensure a smooth and even finish, enhancing both overall aesthetics and usability.

2. Spacing

Furring channels can also provide space for electrical wiring, pipes, and other utilities in a building without moving materials. This design feature allows for greater construction flexibility and reduces design constraints caused by material space occupation.

3. Providing Strength and Stability

Furring channels are ideal frames for fixing gypsum board, fiber cement board, and other cladding materials, providing exceptional strength and durability. They ensure a smooth and even surface while providing excellent stability when carrying heavy loads.

4. Suitable for Various Building Requirements

Whether for commercial or residential projects, furring channels are an excellent solution for high-performance suspended ceiling systems. Their design flexibility allows them to adapt to different architectural styles and requirements, providing more possibilities for construction.

Get the latest price? We'll respond as soon as possible(within 12 hours)