How Much Does a Mechanical Power Press Cost?

2025-11-05 17:00

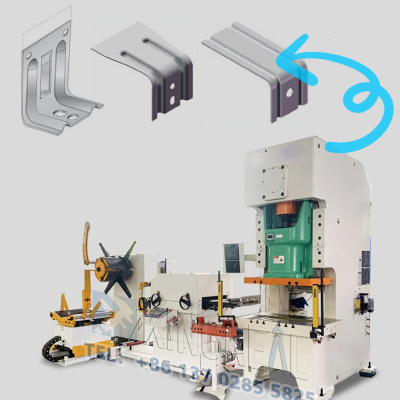

A mechanical power press is a device that uses compressed air supplied by an air pump, which passes through a solenoid valve into a cylinder, driving a piston downward to generate punching force. Progressive die mechanical press is mainly used for cutting, punching, and stretching metal sheets or wires. The die assembly of a mechanical power press consists of upper and lower parts, which form holes or achieve deformation in the work-piece through pressing. Depending on the drive method, progressive die mechanical presses can be divided into mechanical (including flywheel and clutch) and body-structured types, mainly covering open (C-type, primarily below 300 tons) and closed (O-type) structures. Their transmission structures are further divided into crankshaft type (suitable for punching and bending), eccentric wheel type (with excellent rigidity and lubrication performance), and toggle linkage type (with bottom dead center pressure holding characteristics).

The emergence of mechanical power presses has brought significant improvements in production efficiency and quality to the processing industry. Therefore, many customers purchasing progressive die mechanical presses are very concerned about price, as it is often one of the most important factors in their purchase decision. This article will take KINGREAL CEILING MACHINERY mechanical power press as an example to explore the various factors affecting price.

Factors Affecting Price of Mechanical Powered Press

As a professional manufacturer of progressive die mechanical presses, KINGREAL CEILING MACHINERY excels at providing customized mechanical power press manufacturing solutions based on the actual project needs of customers. Therefore, the parameters, performance, and accessories of the mechanical power presses offered vary, resulting in price differences that cannot be summarized by a fixed figure.

1. Tonnage of progressive die mechanical press

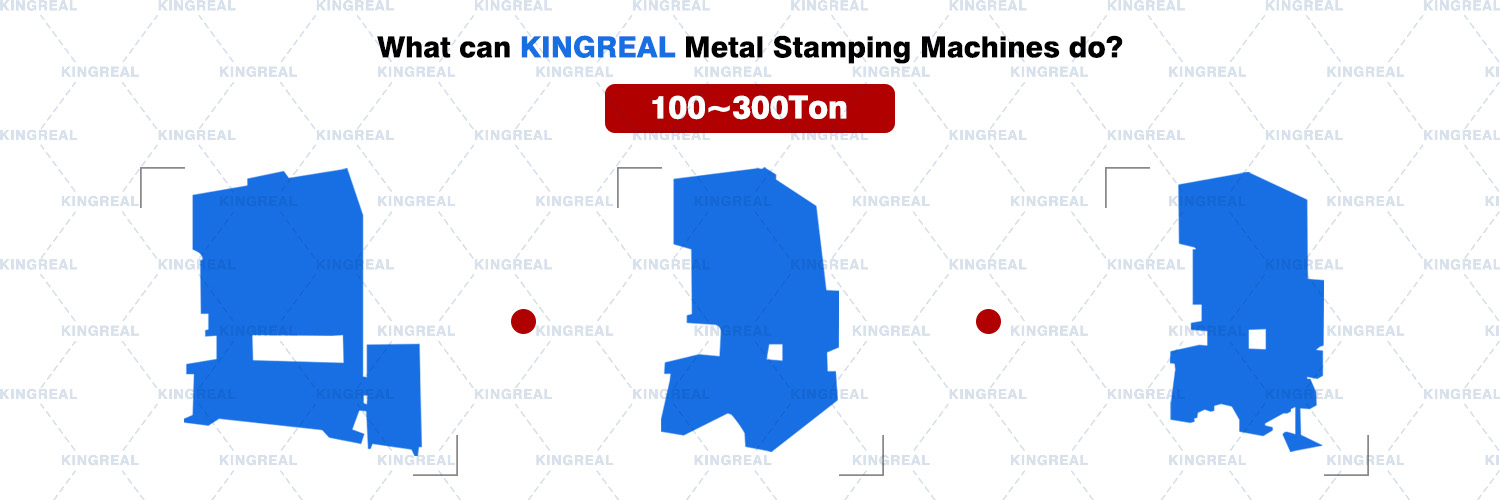

The tonnage of a mechanical power press is one of the most important factors affecting its price. Typically, KINGREAL CEILING MACHINERY can provide punch presses ranging from 100 to 300 tons. Specific tonnage requirements are related to several factors, including the hole shape, material width, material type, and material thickness. KINGREAL CEILING MACHINERY engineers will provide reasonable tonnage recommendations based on the client's actual needs to ensure optimal performance during processing.

2. Dies for progressive die mechanical press

The design and manufacture of dies also directly impact the price of mechanical power presses. KINGREAL CEILING MACHINERY can provide multiple dies to meet client needs, allowing a single progressive die mechanical press to produce different types of finished products by changing the dies. Based on the hole shape and diameter drawings provided by the client, KINGREAL CEILING MACHINERY engineers will customize personalized punching dies, which not only improves production flexibility but can also affect the price.

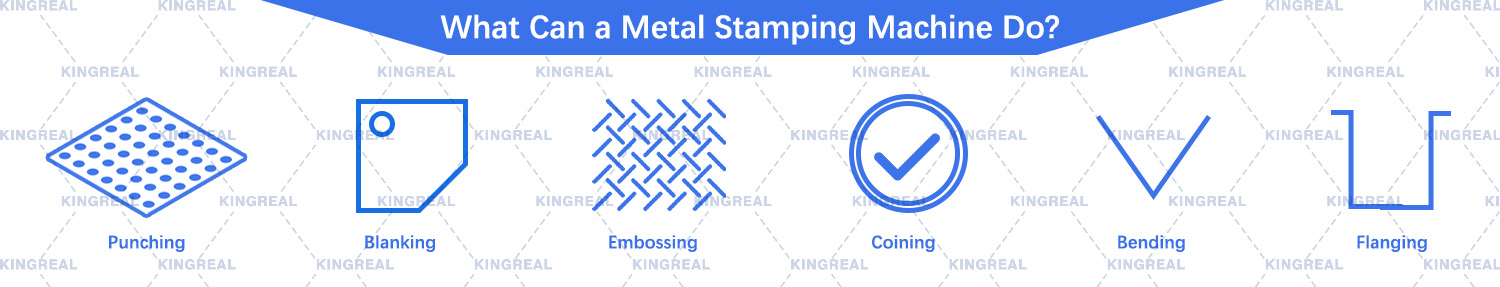

3. Functions of mechanical power press

The various functions of a progressive die mechanical press, such as punching, blanking, embossing, stamping, bending, and flanging, all affect the price. KINGREAL CEILING MACHINERY engineers will design according to the specific processes required by the customer; the more functions and the more complex the design, the higher the price will be.

4. Production speed of mechanical power press

Generally speaking, the faster the progressive die mechanical press, the higher its price. This is because increasing production speed often requires higher technical specifications and more complex control systems to ensure that product quality and processing accuracy are maintained while producing quickly. For enterprises, although investing in high-speed mechanical power presses has a higher initial cost, it can save time and labor costs and improve overall efficiency in the long run.

Mechanical Power Press Solutions

KINGREAL CEILING MACHINERY provides customized progressive die mechanical press solutions for customers, tailored to their needs and industry applications. For example, in different application fields such as automotive, electronics, and home appliances, customers have significantly different requirements for the parameters, performance, and functions of mechanical power presses. KINGREAL CEILING MACHINERY professional team can design the most suitable mechanical power press solutions based on industry characteristics and specific customer requirements, ensuring that the progressive die mechanical press meets production needs.

Important Considerations When Purchasing a Mechanical Power Press

Several key factors need to be considered when purchasing a progressive die mechanical press:

1. Supplier selection

Selecting a dependable mechanical power press supplier is imperative. Along with high-quality progressive die mechanical presses, KINGREAL CEILING MACHINERY also provides a variety of value-added services like factory visits, tailored mechanical power press design, progressive die mechanical press construction, installation, maintenance, and replacement part supply. These services guarantee all-around post-purchase support, therefore lowering later running expenses and maintenance.

2. Maintenance and upkeep for mechanical power press

Long-term stable functioning of the progressive die mechanical press depends on daily maintenance and routine upkeep. Regular checks and upkeep not only lengthen the life of the mechanical power press but also guarantee output stability. KINGREAL CEILING MACHINERY advises clients to create a thorough maintenance plan to guarantee that every progressive die mechanical press runs in perfect shape, therefore preventing needless downtime and repair expenses.

3. Performance and applicability

Customers also have to take into account whether the progressive die mechanical press's performance fulfills their production needs when choosing mechanical power press. Customized mechanical power press solutions depending on clients' particular process needs guarantee the performance and effectiveness of the mechanical power press in actual applications; KINGREAL CEILING MACHINERY can provide these solutions.

If you have any questions or needs regarding mechanical power presses, please feel free to contact KINGREAL CEILING MACHINERY.

Get the latest price? We'll respond as soon as possible(within 12 hours)