Metal Ceiling Tiles Molds Sets

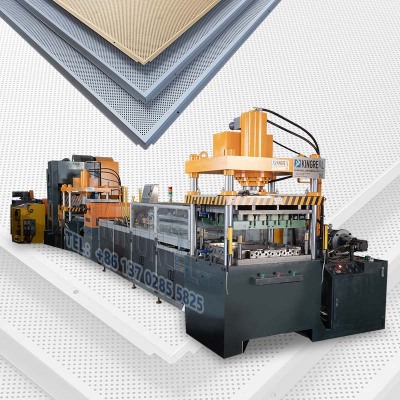

The metal ceiling tiles punching mold sets are used with the metal ceiling tile bending machine. It supports various product types, including CLIP IN Ceiling Tiles, LAY IN Ceiling Tiles, TEGULAR ON Ceiling Tiles, LAY ON Ceiling Tiles, and ACCESS PANEL TILES. The system can be operated manually or fully automated, featuring an automatic robotic arm. Key features include an air cooling system, a well-known brand hydraulic system, and a safety light curtain protection.

- KINGREAL CEILING MACHINERY

- China

Details

Display About Metal Ceiling Tile Bending Machine

KINGREAL CEILING MACHINERY Successful Cases in Global

With years of penetration into the metal working equipment market, KINGREAL CEILING MACHINERY has stocked many successful cases and localized technical support experience:

2. Metal Ceiling Tile Perforation Line

3. Gantry Type Press Machine

4. Notching and Shearing Press Machine

5. Metal Ceiling Press Machine

And so on...

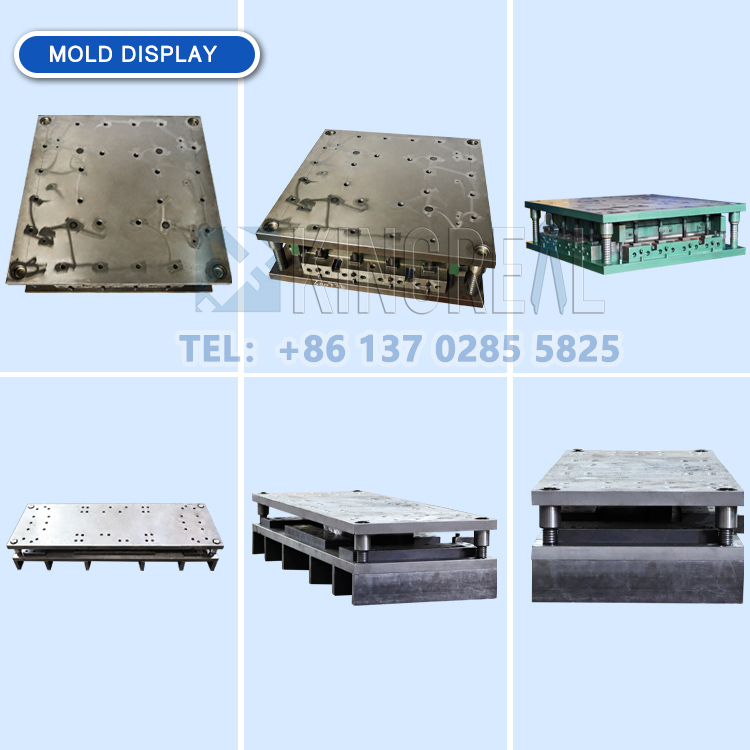

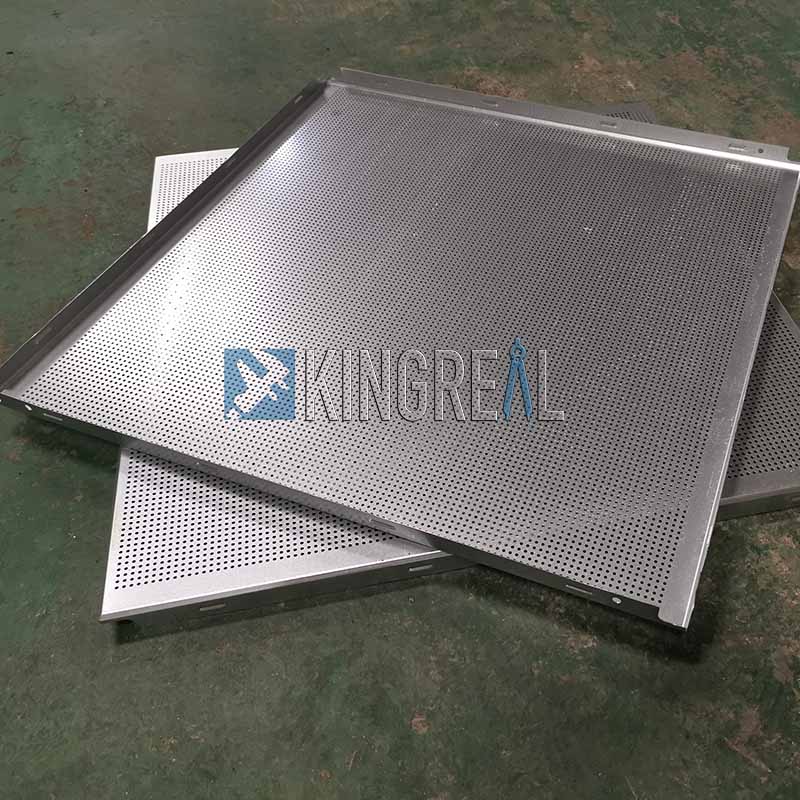

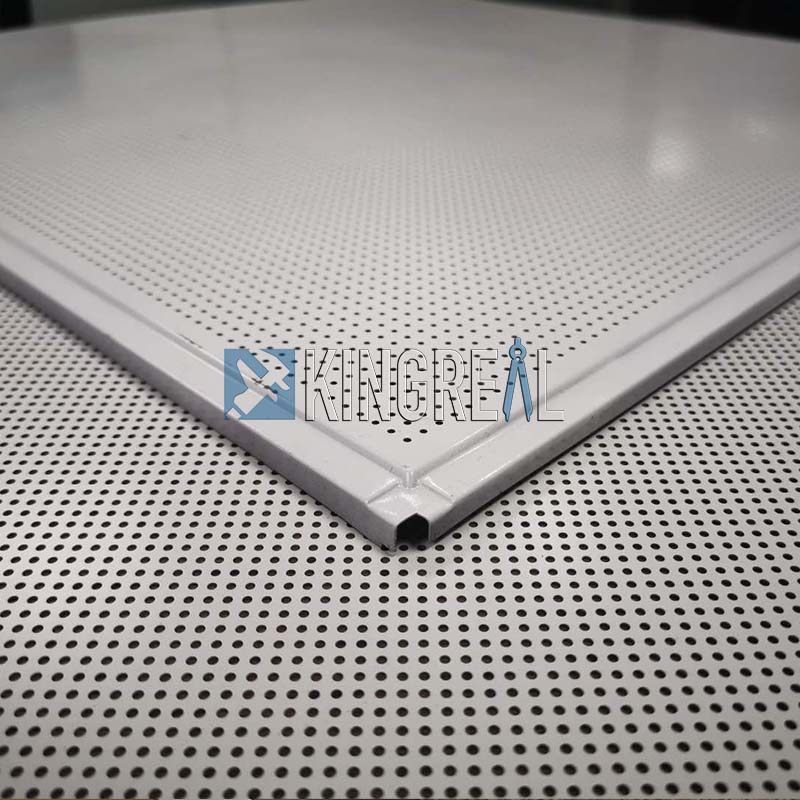

Description of Metal Stamping Die

KINGREAL CEILING MACHINERY can provide high-quality, durable and high-precision punching molds for 300x300mm metal ceiling machines, 600x600mm metal ceiling machines, 600x1200mm metal ceiling machines and other different types of metal ceiling machines.

And can provide bending forming molds to produce various types of metal ceiling tiles such as clip in ceiling tiles, lay in ceiling tiles, tegular ceiling tiles, etc. These molds use slow wire cutting technology to ensure high precision and high-quality cutting effects for customers.

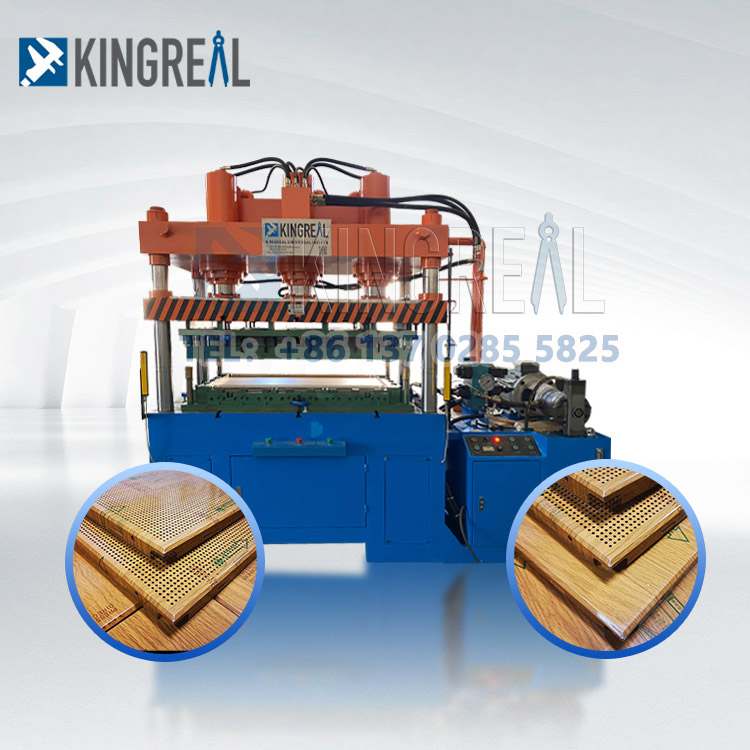

KINGREAL CEILING MACHINERY uses four column hydraulic press to do the four sides of corner cutting for the perforation metal sheet. For different sizes of metal suspended ceiling tiles, KINGREAL CEILING MACHINERY uses different capacities of hydraulic press.

After the corner cutting, the sheet can be formed on the bending forming press.

Application In Different Type of Metal Ceiling Tile

1. CLIP IN CEILING TILE PUNCHING MOLDS

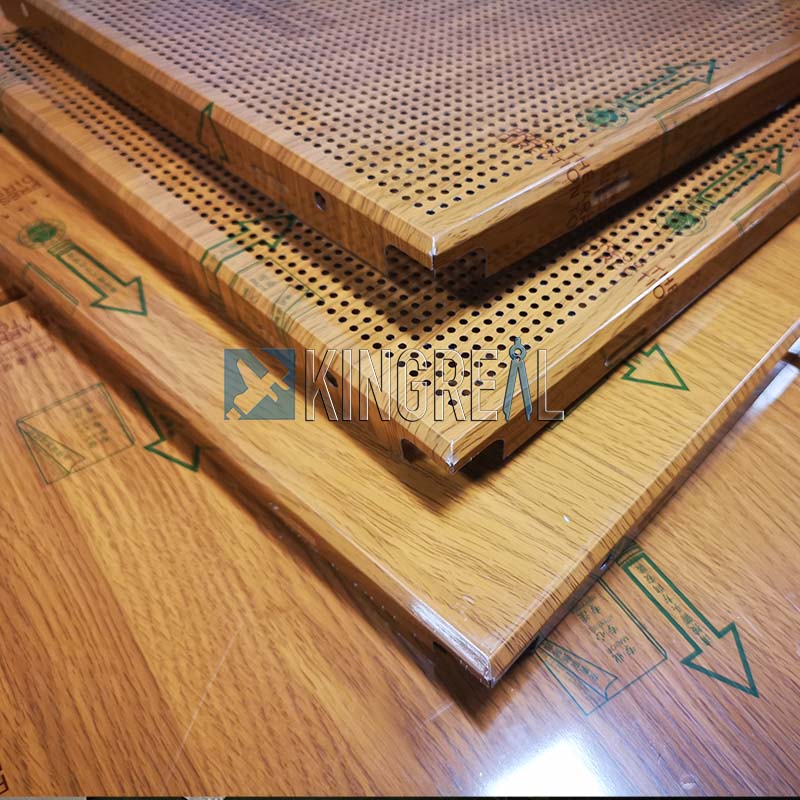

CLIP IN ceiling tile is one of the most popular designs on the market. The clip in ceiling system features a hidden support structure with removable panels that snap into place on the triangular omega main runner.

The grid system is invisible, making it more aesthetically pleasing and more visible than other types of metal ceiling systems. All panels can be removed individually, allowing quick and easy access from above the metal ceiling.

2. LAY IN CEILING TILE PUNCHING MOULDS

For LAY IN ceiling tile, there are different types on the market, most popular is 575*575mm exposed for T24 system and 585*585mm exposed for T15 system. These two kinds of metal ceiling tiles also need to be produced by changing the notching and bending forming molds.

3. LAY ON CEILING TILE Metal Casting MOLDS

KINGREAL CEILING MACHINERY uses four column hydraulic press to do the four sides of corner cutting for the perforation metal sheet. For different sizes of metal ceiling tiles, KINGREAL CEILING MACHINERY uses different capacities of hydraulic press. After the corner cutting, the sheet can be formed on the bending forming press.

4. TEGULAR CEILING TILE Metal Punching Dies

KINGREAL CEILING MACHINERY uses four column hydraulic press to do the four sides of corner cutting for the perforation metal sheet. For different sizes of metal ceiling tiles, KINGREAL CEILING MACHINERY uses different capacities of hydraulic press. After the corner cutting, the sheet can be formed on the bending forming press.

5. ACCESS PANEL CEILING TILE BLANKING MOLDS

KINGREAL CEILING MACHINERY metal ceiling tile production line and metal stamping die are one of KINGREAL CEILING MACHINERY most featured products.

Final Product Display

KINGREAL CEILING MACHINERY Technical Team

KINGREAL CEILING MACHINERY has a professional technical team with more than 25 years of relevant experience from the drawing design to the manufacturing of Suspended Ceiling Panel Making Machine, from design - production - installation - after-sales, KINGREAL has excellent standards.

Services are always highly considered by us, in addition to establishing a complete remote service system, localized after-sales service is also what KINGREAL CEILING MACHINERY has been insisting on doing. The global localization service point is under construction.

Quality Insurance

KINGREAL CEILING MACHINERY has passed ISO9000 certification and has the ability of ISO9000 quality system management. After you order, KINGREAL CEILING MACHINERY technical team will test the machine in an effort to ensure every mechanical and electrical part is in perfect condition.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)