How to perforate sheet metal by steel perforated machine?

2025-08-05 17:00

Steel perforated machines are quite versatile and find application in electronics, aerospace, machinery manufacture, and many more sectors.Along with better material use, punching increases the performance of the finished product.

This article will provide a detailed introduction to metal perforated making machines for sheet metal, covering a basic introduction to steel perforated machines, the punching process, key terminology, and precautions.

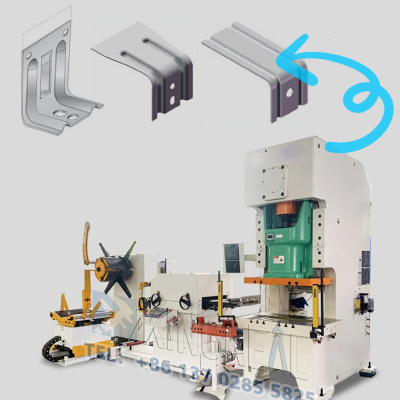

1/ Basic Introduction to Metal Perforated Making Machine

A steel perforated machine is a device specifically designed for punching holes in sheet metal. It can handle metal materials ranging from 0.4 to 10mm thick.Round, oblong, square, triangular, diamond, hexagonal, and cross holes are among the common hole patterns.

To satisfy a range of consumer needs, the metal perforated making machine may modify punching dies based on customer sketches to get particular hole sizes and patterns.

2/ Steel Perforated Machine Configuration and Components

Depending on customer production requirements, the metal perforated making machine can be equipped with a variety of additional components, such as:

Feeding trolley: Automatically feeds the sheet metal to improve production efficiency.

Metal sheet cleaning machine: Cleans the sheet metal before punching to ensure punching quality.

Unloading trolley: Transport the perforated coil to the designated area.

Vacuum scrap suction: Efficiently removes scrap generated during the punching process, maintaining a clean work environment.

Combining these accessories makes the steel perforated machine's whole function more automatic and effective, therefore fitting for production needs of diverse sizes and kinds.

3/ How Does a Steel Perforated Machine Perform Punching?

The punching process can be divided into several key steps to ensure optimal results at each step.

1. Selecting the Appropriate Punching Tools and Equipment

Choose the right punch, die, and press according on aspects like the material's characteristics, form, and size before punching.Various materials and hole kinds call for distinct equipment and instruments.Thicker metal sheets, for instance, call for heavier tonnage presses and bigger punches.

2. Installing the Punching Equipment

Making sure everything is properly aligned, put the punch, die, and workpiece on the press.This stage is very important; faulty installation might damage the steel perforated machine or cause deviation during the punching process.

3. Adjusting Punching Parameters

Adjust key punching parameters based on the workpiece's material, shape, and size. These include:

Punching Pressure: Ensure the punch applies sufficient force to penetrate the metal sheet. Punching Speed: Optimize the punching speed to ensure production efficiency while avoiding quality issues caused by excessive punching speed.

Number of Punches: Adjust the number of punching cycles based on the number of holes required.

Proper parameter configurations can greatly enhance punching efficiency and quality.

4. Punching Operation

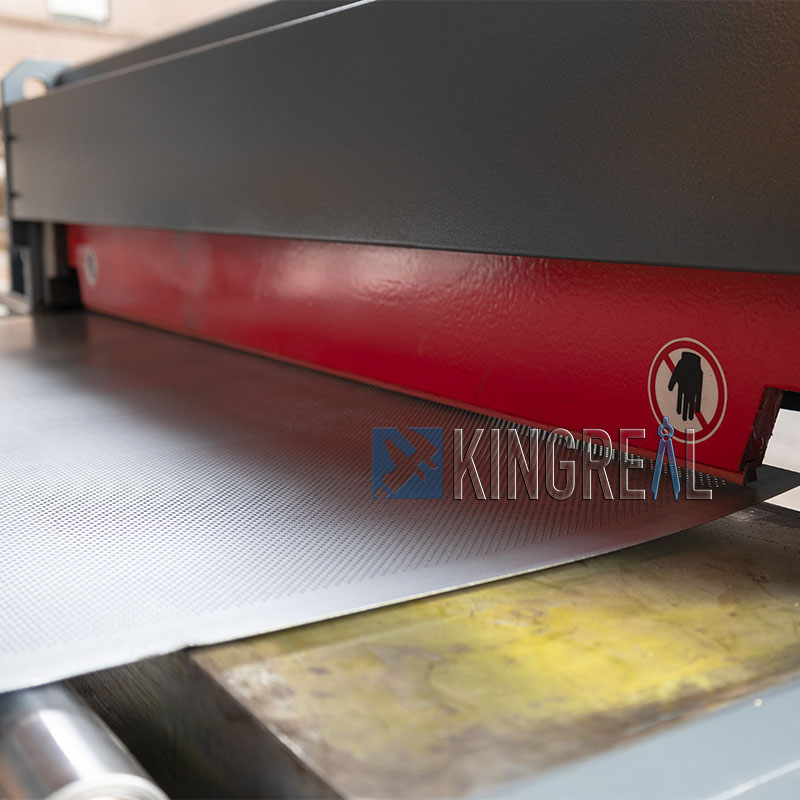

The punch head touches the workpiece, exerts pressure, and finishes the punching operation when the metal perforated machine is activated.The operator must watch the punching status closely throughout this procedure to make sure everything is running as intended.

5. Cleaning and Inspection

Ensure there are no metal fragments or other trash that might interfere with following handling by wiping any residue from the struck surface after punching.Additionally conducted to verify that hole design, position, and size satisfy requirements, quality inspection should confirm this.

4/ Applications of Metal Perforated Making Machine in Metalworking

Steel perforated machine has a wide range of applications in metalworking. Used to create a range of components, casings, and structural members, it is especially successful in the following fields:

Mechanical Manufacturing: Used to create machine components, strengthening and durability improvement. Aerospace: Punching helps reduce weight and increase strength in aircraft and spacecraft structures. Electronics and Electrical: Improving heat distribution, used in the manufacture of internal parts and electrical enclosures. Manufacturers may use materials more effectively, cut waste, and cut production costs thanks in part to the punching method. |  |

5/ Key Terms for Steel Perforated Machines

When understanding a metal perforated making machine and its operation, it's important to master the relevant terminology. Here are some basic terms:

| Die | A specialized tool used in a punching press to form and cut metal parts. |

| Punch | A component of a punching press that applies force to form the desired hole pattern in sheet metal. |

| Stamping | The process of cutting flat shapes from sheet metal. |

| Piercing | The process of creating a hole in sheet metal using a punch and die. |

| Forming | The process of using a die to bend or shape metal into a desired structure. |

| Tonnage | The maximum force a punch can exert, usually measured in tons. |

| Stroke Length | The distance the punch travels during the punching process. |

| Speed | The rate at which a punching press performs operations, measured in strokes per minute. |

Die Pad | A component that supports the blank during the forming process to minimize wrinkles and control material flow. Quick Die Change System: A mechanism that allows for quick and efficient die changes, reducing downtime between production runs. |

Automation | The integration of robotic systems with computer controls to optimize production processes and minimize human intervention. |

| CNC (Computer Numerical Control) | A computer system that automatically controls a punching press, enabling precise, repeatable operation. |

Get the latest price? We'll respond as soon as possible(within 12 hours)