What is sheet metal stamping press?

2025-08-03 17:00

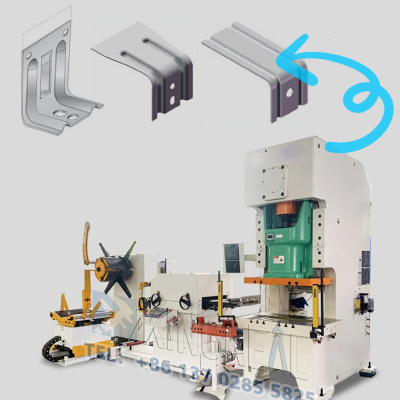

| In modern manufacturing, sheet metal stamping presses have become essential tools for the efficient production of high-quality metal brackets. High efficiency and high-quality metal brackets produced to close tolerances are offered by KINGREAL CEILING MACHINERY sheet metal stamping machines. Highly versatile across a number of sectors, these sheet metal stamping presses can satisfy clients' demands for low, moderate, and high-volume jobs. The operating theory, major parts, benefits, and general production process of sheet metal stamping machines will be discussed here. |  |

1/ Introduction to Sheet Metal Stamping Press

Specifically made to handle sheet metal, a sheet metal stamping machine is a adaptable piece of equipment.

Used in conjunction with progressive dies, it is suited for fine blanking, shaping, riveting, and extrusion as well as punching, forming, deep drawing, cutting. Industries like household appliances, car components, and any industry requiring quick and effective metal coil processing use these sheet metal stamping presses widely.

Designed to rapidly create great numbers of small metal brackets, sheet metal stamping machines These sheet metal stamping machines are absolutely necessary in several sectors since they are well-known for their extraordinary accuracy, outstanding surface quality, and extended die life.

2/ How a Sheet Metal Stamping Press Works?

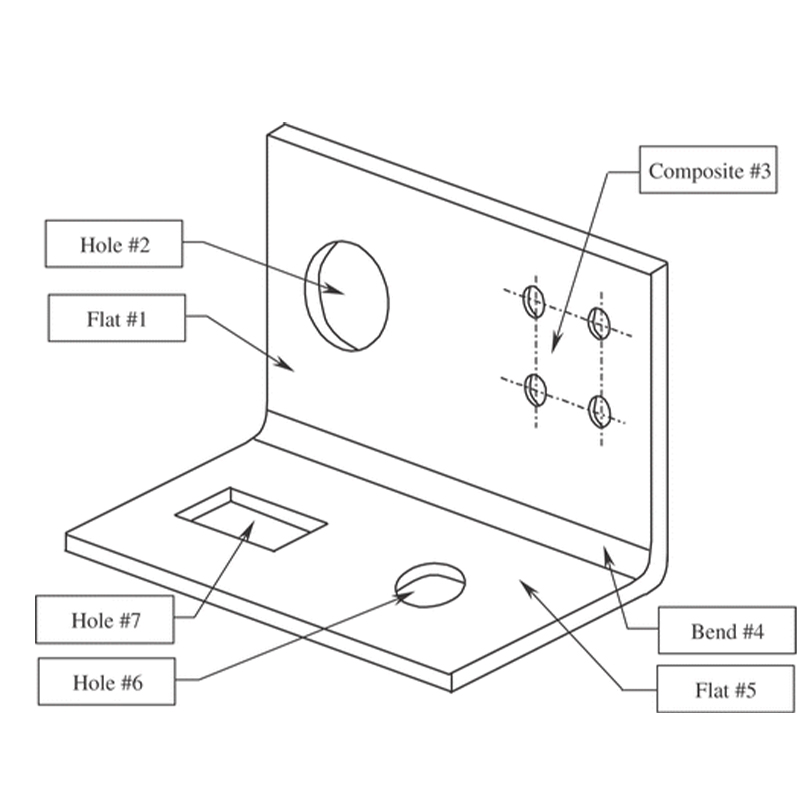

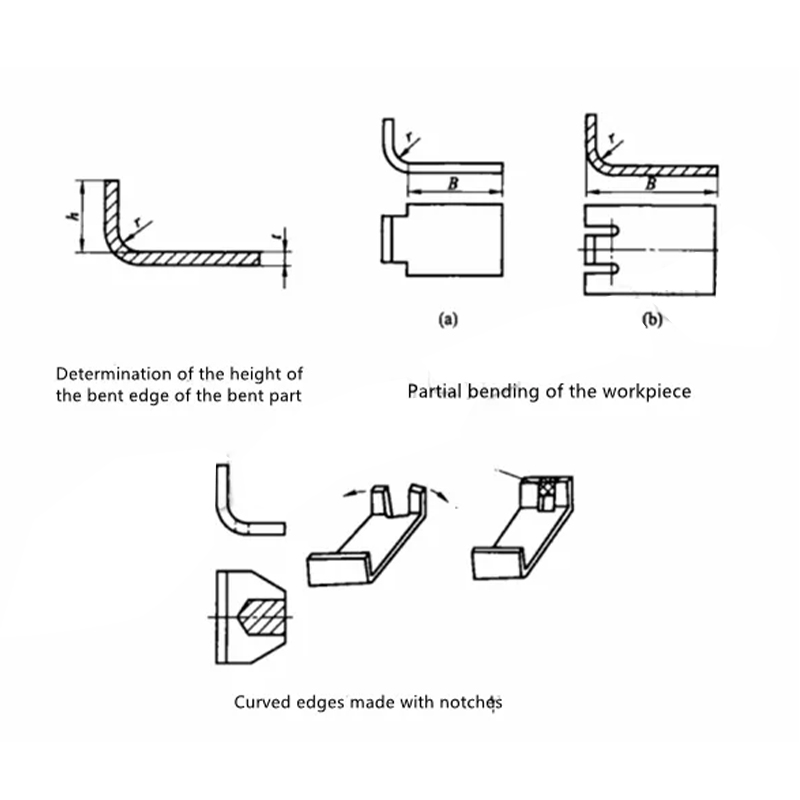

Generally speaking, progressive dies allow sheet metal stamping machines to perform the punching, bending, and shaping of sheet metal. For large-volume manufacturing especially, where precise size and shape of metal brackets are vital, this approach is most appropriate. A coil of metal starts the process by being fed into the press, where the dies mould the metal. Embossing, blanking, punching, piercing, and flanging are among common activities.

Progressive dies comprise a series of stamping operations wherein the metal piece is further bent or punched until it is finished. Perfect for high-volume production, this step-by-step method maximizes efficiency and reduces waste.

3/ Key Parameters of Sheet Metal Stamping Presses

| Raw Material Types | Hot-rolled steel, cold-rolled steel, galvanized steel, stainless steel, etc. |

| Yield Strength | ≤400 N/mm² |

| Tensile Strength | ≤640 N/mm² |

| Coil Width | 100-1600 mm |

| Material Thickness | Options include 0.3-3.2 mm, 0.4-4.5 mm, and 0.6-6.0 mm |

| Maximum Coil Weight | Up to 10 tons |

These parameters ensure that the sheet metal stamping machine can handle a wide range of materials and thicknesses to suit diverse manufacturing needs.

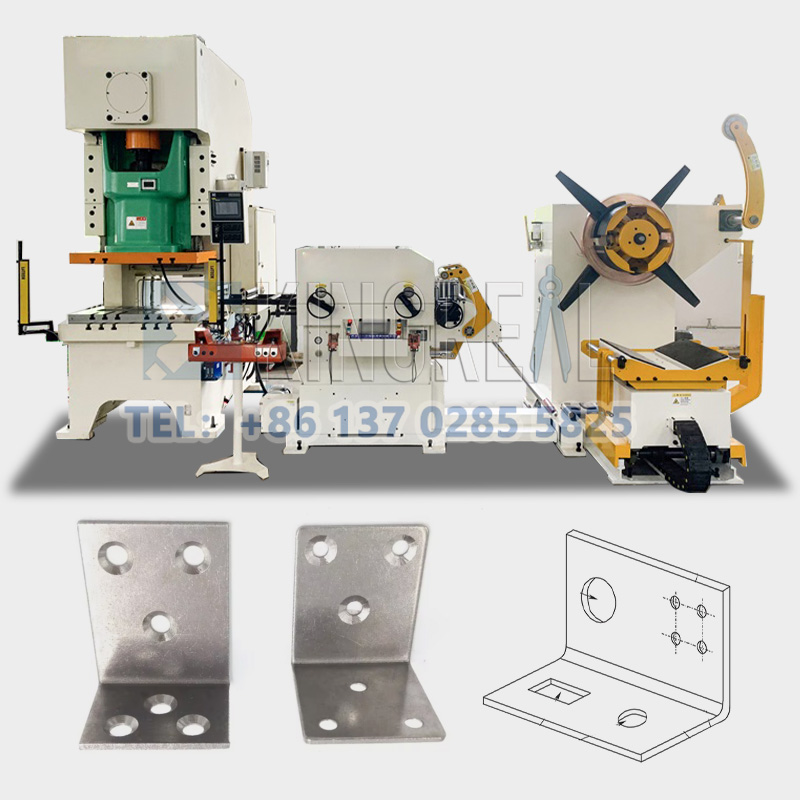

4/ Workflow of Sheet Metal Stamping Press

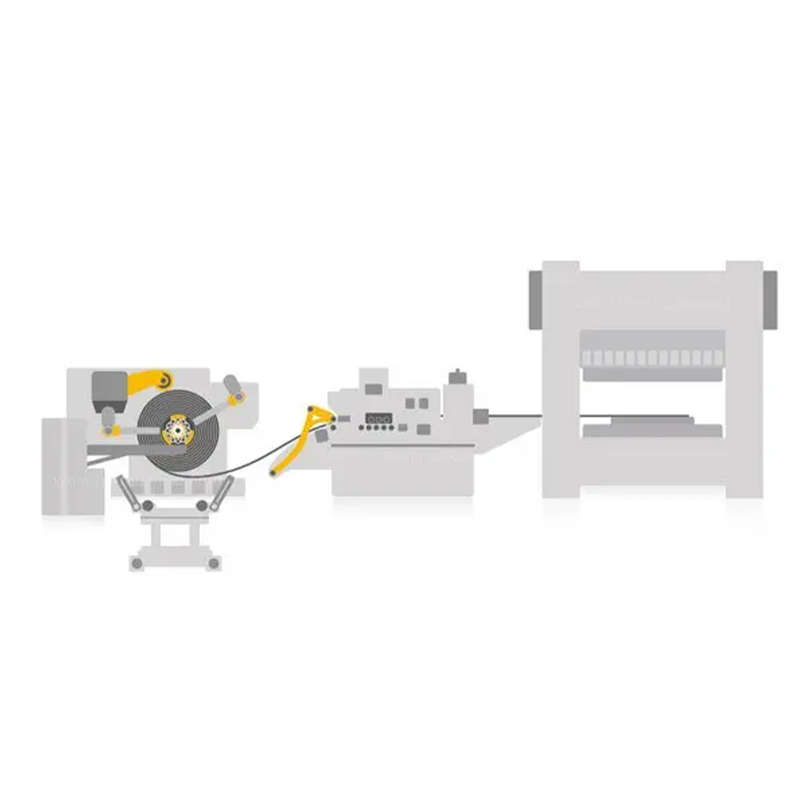

Decoiler- Leveling Machine- Power Press |  |

5/ Main Components of Sheet Metal Stamping Machine

Decoiler for sheet metal stamping press: This equipment uncoils metal coils, including stainless steel, aluminum, iron, and copper. This step is crucial as it lays the foundation for subsequent operations.

Leveling machine for sheet metal stamping machine: This equipment flattens the unwound metal sheet, ensuring a smooth surface, which is essential for precise punching and bending. This process helps eliminate any residual stress in the material.

Power press for sheet metal stamping press: Utilizing progressive dies, this machine performs bending and punching operations to produce metal parts to customer specifications.

6/ Advantages of Using a Sheet Metal Stamping Machine

1. Modular control and user-friendly operation for sheet metal stamping press

The sheet metal stamping press is designed for integrated operation, consisting of an decoiler, leveling machine, and power press.

The entire sheet metal stamping machine is connected via a PLC control system and operated via a touchscreen, making it easy to manage and adjust settings according to production needs.

2. Reliable structural design for sheet metal stamping press

KINGREAL CEILING MACHINERY uses CNC machining centers, grinders, boring machines, lathes, and a range of precision testing equipment—stateoftheart equipment—in its sophisticated quality control procedures. This guarantees great accuracy and quality throughout all parts of the sheet metal stamping machine.

3. High-quality sheet metal stamping press

Thanks to the employment of internationally recognized core parts, automatic lubrication systems, and selfdiagnosis systems, the sheet metal stamping machine offers a low failure rate and simple maintenance. This dependability lowers downtime and raises production efficiency.

7/ Progressive Die Design and Manufacturing

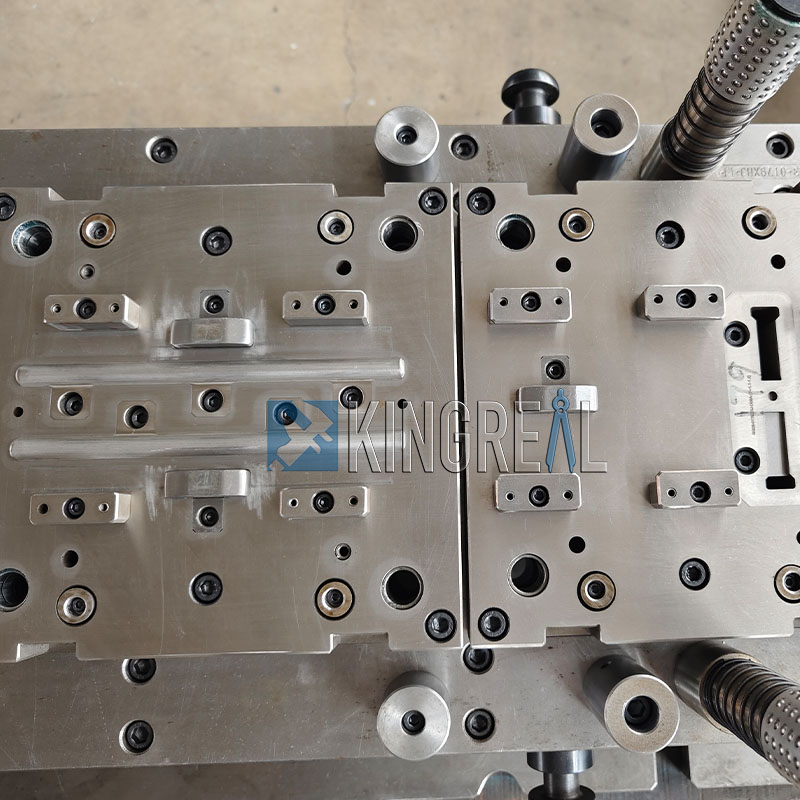

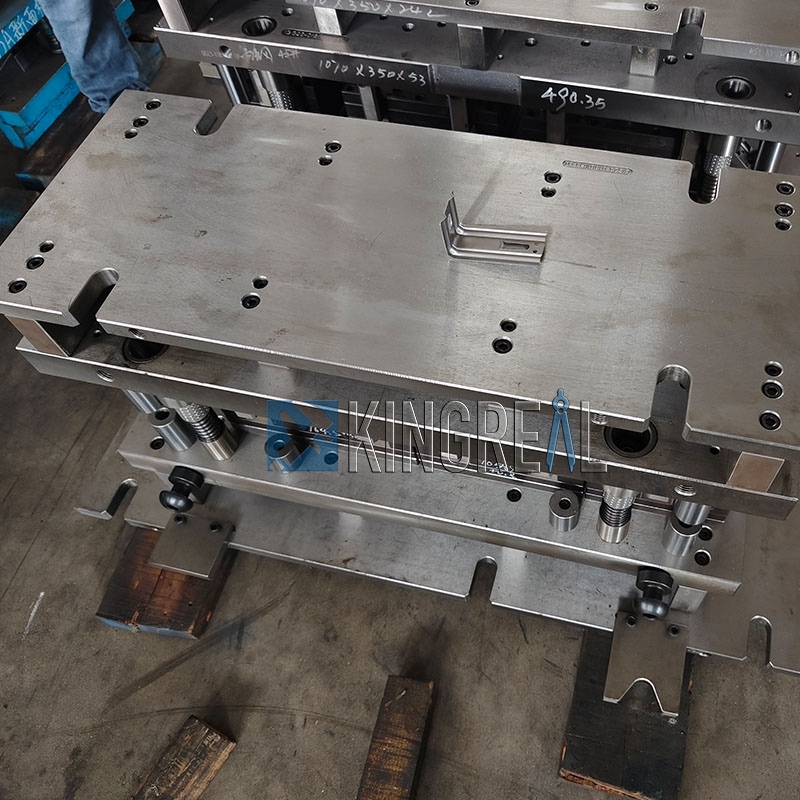

KINGREAL CEILING MACHINERY engineers collaborate with customers in the early design stages to design custom sheet metal stamping presses and corresponding dies based on their drawings and actual production requirements.

This collaborative relationship ensures that parts produced meet precise specifications and quality standards.

KINGREAL CEILING MACHINERY provides custom mold manufacturing services for domestic and international clients. High-quality molds are crucial to ensuring our clients receive quality parts upon production.

Once the metal molds are under manufacture, KINGREAL CEILING MACHINERY team works to regularly maintain and repair them to guarantee best performance and longevity.

Buying a sheet metal stamping machine is a calculated move with great returns as demand for many different types of metal brackets grows. This essay offers a more thorough grasp of the operating principles, benefits, and specifications of sheet metal stamping presses so you can make an educated decision to raise product quality and production.

Please get in touch with KINGREAL CEILING MACHINERY if you want to buy a sheet metal stamping machine and require further details about related specifications.

Get the latest price? We'll respond as soon as possible(within 12 hours)