Metal Powder Coating Production Line

Metal Powder Coating Production Line can be used in conjunction with the metal ceiling machine, featuring optimal powder utilization and excellent adhesion.

- KINGREAL CEILING MACHINERY

- China

- 90 Days

- 9999

Details

Video About Metal Powder Coating Line

What is a Metal Powder Coating Production Line?

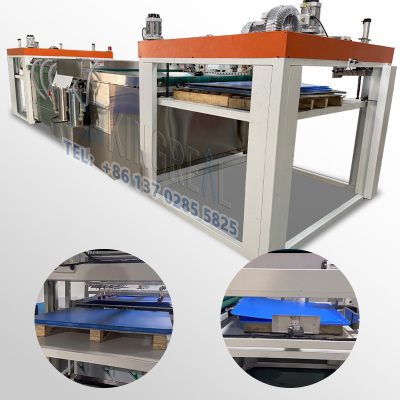

In modern industry, the Metal Powder Coating Production Line is an indispensable technology. KINGREAL CEILING MACHINERY high-quality Metal Powder Coating Line is not only easy to construct, but also can efficiently achieve fast and consistent coating of metal ceiling tiles of different types and sizes. This Metal Powder Coating Line is designed with full consideration of quality control to ensure that every metal ceiling board can get the best powder coating effect. Through KINGREAL CEILING MACHINERY Metal Powder Coating Production Line, metal parts will undergo four key processes to effectively protect the surface of the metal ceiling tile. These four processes cover pretreatment, powder coating, curing and cooling, ensuring that each metal ceiling board has a durable and firmly bonded surface to extend its service life. |  |

Workflow of Metal Powder Coating Line

The work flow of Metal Powder Coating Production Line is divided into the following important steps:

Pretreatment for Metal Powder Coating Line: At this stage, KINGREAL CEILING MACHINERY Metal Powder Coating Line will clean the metal ceiling board to remove impurities and contaminants on the surface. The purpose of pretreatment is to improve the adhesion of powder and lay a solid foundation for the subsequent powder coating process.

↓

Powder coating for Metal Powder Coating Line: Through electrostatic adsorption technology, the powder can be evenly attached to the surface of the metal ceiling tile. This process ensures the uniformity and consistency of the powder coating, avoiding the color difference and unevenness that may occur in traditional manual spraying.

↓

Curing for Metal Powder Coating Line: Under high temperature, the powder will level and form a solid coating film. This process not only enhances the adhesion of the coating, but also improves its durability and corrosion resistance.

↓

Cooling for Metal Powder Coating Line: Finally, the coating is stabilized through the cooling process. The cooled metal ceiling board will have stronger wear resistance and beautiful appearance.

Through this series of fine processes, KINGREAL CEILING MACHINERY Metal Powder Coating Production Line ensures that every metal ceiling tile can meet high standards of quality requirements.

Cooperation Between Metal Powder Coating Line and Metal Ceiling Machine

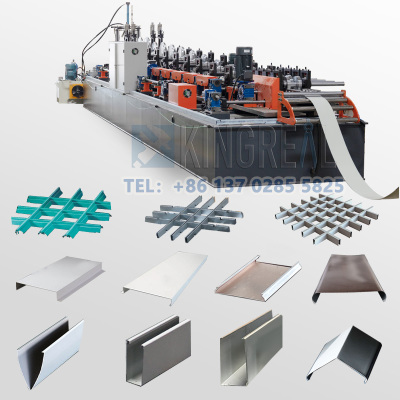

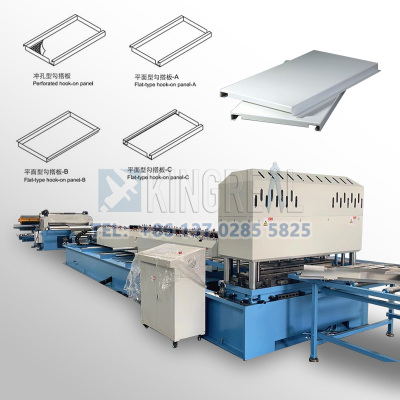

| KINGREAL CEILING MACHINERY Metal Powder Coating Production Line can be used in close combination with various types of metal ceiling machines. Whether it is a 30x30cm metal ceiling machine, 60x60cm metal ceiling tile production line, 60x120cm metal ceiling machine, or a clip in metal ceiling tile production line, lay in metal ceiling machine, aluminum metal ceiling tile production line, etc., the Metal Powder Coating Line can provide efficient services. |  |

When you have a Metal Powder Coating Production Line, after the metal ceiling tile is produced, the metal ceiling board can be quickly put into the Metal Powder Coating Line to complete the whole process from metal ceiling tile production to upgrading. This seamless connection not only improves production efficiency, but also ensures the quality of the final product. No matter which country you are in, choosing KINGREAL CEILING MACHINERY Metal Powder Coating Production Line will bring significant improvement to your metal ceiling machine. Metal Powder Coating Lines are widely used in many countries, such as the United States, Germany, the United Arab Emirates, Saudi Arabia, etc., due to the continuous increase in demand for metal ceiling tiles in the construction industry and the local emphasis on the beauty and durability of products. Metal Powder Coating Production Lines are widely used. The demand of these countries mainly stems from the emphasis on the beauty, durability and environmental protection of building materials. The Metal Powder Coating Line can effectively improve the quality of the metal ceiling tile and meet the market's expectations for high-performance products. |  |

Advantages of Metal Powder Coating Production Line

Optimal powder utilization: KINGREAL CEILING MACHINERY Metal Powder Coating Line design ensures that every gram of powder can be effectively utilized, reducing waste and reducing production costs. By optimizing the spraying process, it is ensured that the powder can fully cover the surface of the ceiling, thereby achieving efficient production results.

Excellent adhesion: KINGREAL CEILING MACHINERY Metal Powder Coating Production Line uses electrostatic spraying technology, which can achieve uniform powder coating, which is faster and more accurate than manual spraying. The powder coating has extremely strong adhesion and can effectively resist peeling and falling off, ensuring the long-term use of the metal ceiling board in harsh environments. |  |

Efficient curing: The curing system of KINGREAL CEILING MACHINERY Metal Powder Coating Line is designed with high-temperature rapid leveling technology, which greatly shortens the curing time and improves production efficiency. Through the precise temperature control system, the coating can be quickly cured after powder spraying, ensuring that the product is quickly put on the market.

Extend the service life of metal ceiling panel: The metal ceiling tile treated by KINGREAL CEILING MACHINERY Metal Powder Coating Production Line has the properties of rust prevention and enhanced strength, and at the same time has a beautiful appearance, which can meet the market's demand for high-quality products. The enhanced corrosion resistance allows the metal ceiling panel to maintain excellent condition in various environments and reduce maintenance costs. |  |

Environmentally friendly coating: KINGREAL CEILING MACHINERY Metal Powder Coating Line uses environmentally friendly powder coatings that meet international environmental standards. Solvent-free and low volatile organic compound (VOC) emissions ensure that the impact of the production process on the environment is minimized, in line with the concept of sustainable development.

Flexible production capacity: KINGREAL CEILING MACHINERY Metal Powder Coating Production Line can flexibly adapt to production needs of different scales, whether it is small batch customization or large-scale production, it can operate efficiently. This flexibility allows manufacturers to respond quickly to market changes and enhance their competitive advantage. |  |

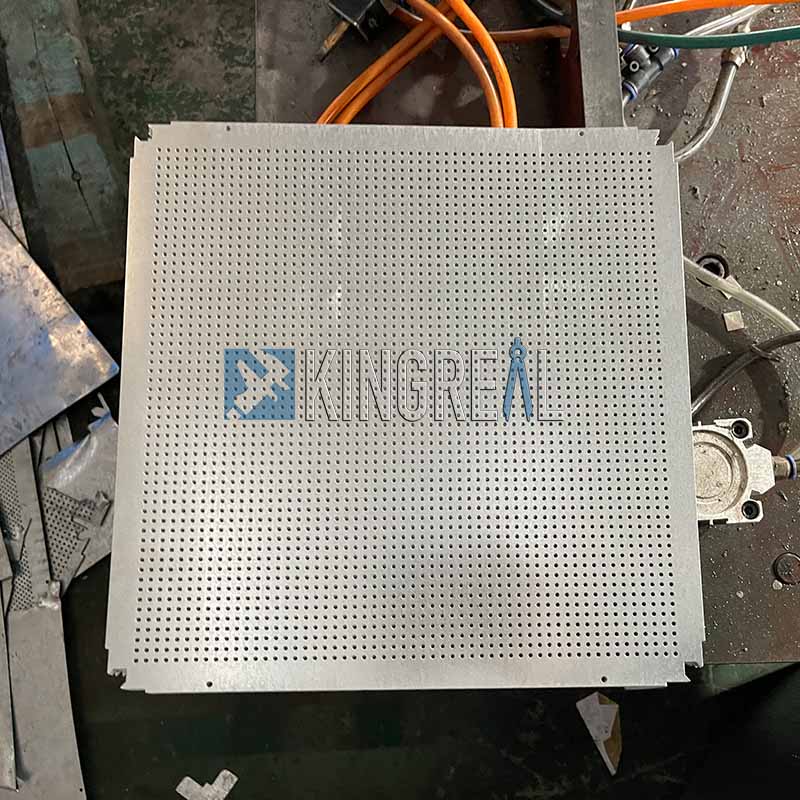

Product Display

| After being processed by KINGREAL CEILING MACHINERY Metal Powder Coating Production Line, the metal ceiling board shows excellent quality. Each metal ceiling tile has a uniform coating, and both the color saturation and surface smoothness have reached the industry-leading level. This not only improves the aesthetics of the product, but also enhances its market competitiveness. |  |

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)