- Home

- >

- Products

- >

- Pop Channel Machine

- >

Pop Channel Machine

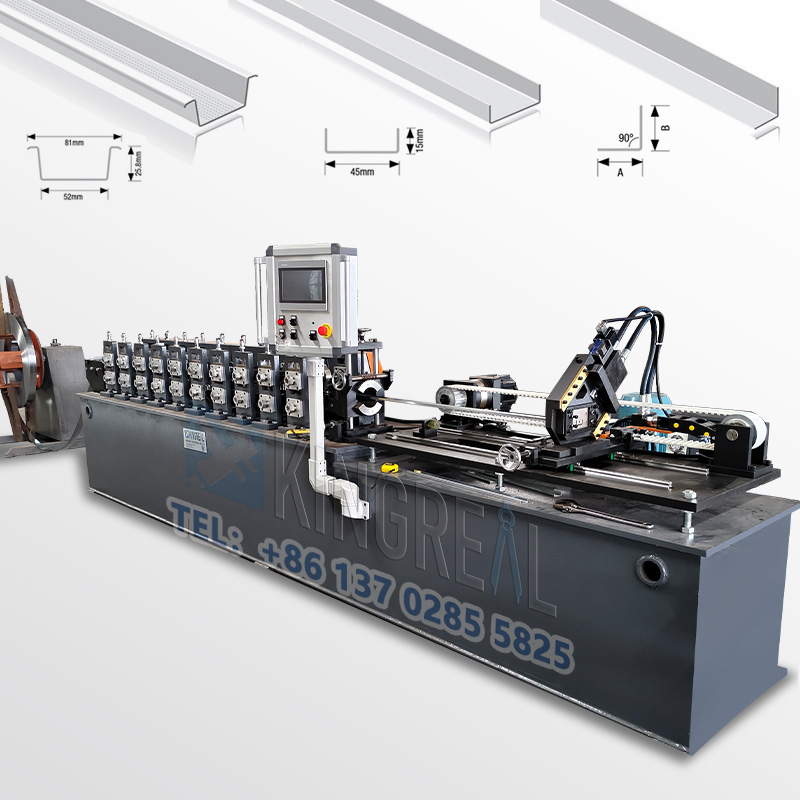

KINGREAL CEILING MACHINERY can provide personalized pop channel making machine manufacturing solutions such as pop patti channel machine, pop bottom channel machine, v-shaped profile machine, etc. according to customer needs.

- KINGREAL CEILING MACHINERY

- China

- 90 DAYS

- 9999

Details

Video About Pop Channel Machine

Definition of Pop Channel Machine

Pop Channel Machine is a special industrial equipment designed to manufacture profiles needed to support suspended ceilings. KINGREAL CEILING MACHINERY can provide personalized Pop channel making machine manufacturing solutions such as pop patti channel machine,pop bottom channel machine, v-shaped profile machine, etc. according to customer needs. These pop channel making machines will produce various shapes of profiles such as U channel, hat channel or L-shaped profile after metal processing according to customer requirements for false ceiling systems. Through these pop channel machines, KINGREAL CEILING MACHINERY provides customers with a complete false ceiling system. |  |

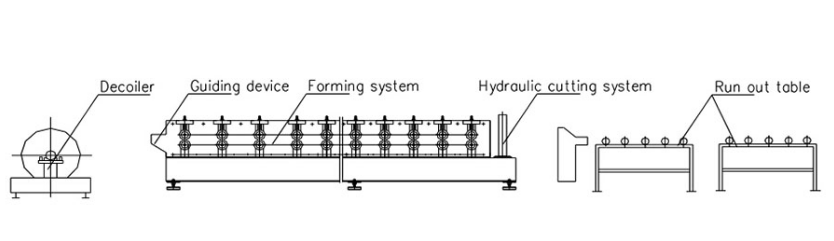

Workflow of Pop Channel Machine

Decoiler ↓ Roll Forming Machine ↓ Cutting Station ↓ Output Table |  |

Advantages of Pop Channel Making Machine

High speed pop channel machine.

This pop channel making machine can operate at a maximum production speed of 120m/min.

Multiple solutions for all pop channel machines.

KINGREAL CEILING MACHINERY has set up multiple solutions for all pop channel machines including pop patti channel machine, pop bottom channel machine, v-shaped profile machine. According to the production speed, KINGREAL CEILING MACHINERY has launched low-speed pop channel machine, medium-speed pop channel machine and high-speed pop channel making machine. The maximum production speed of the high-speed pop channel machine is 120m/min, the production speed of the medium-speed pop channel machine is 60m/min, and the production speed of the low-speed pop channel making machine is 30m/min. Customers can choose the appropriate pop channel making machine manufacturing plan based on their own production scale, cost budget, etc. KINGREAL CEILING MACHINERY engineers will also give suggestions based on years of experience.

Different configurations of the decoiler.

The decoiler is the first main component of the pop channel making machine, which plays the role of quickly unwinding heavy coils. KINGREAL CEILING MACHINERY engineers can configure the pop channel making machine with a single-head decoiler or a double-head decoiler. The single-head decoiler is an ordinary and standard decoiler, while the double-head decoiler can speed up the entire production process for customers. When the left side is unwinding, the right side can be loaded. When the material on the left is used up, turn 180 degrees to continue loading. The pop channel machine will not stop operating due to lack of raw materials, which maximizes the production efficiency for customers.

Multi-specification pop channel machine manufacturing solutions.

In order to meet customers' needs for L-shaped, U-shaped and hat-shaped profiles, KINGREAL CEILING MACHINERY engineers designed a pop channel machine that can produce three types of profiles by replacing the hanger of the roll forming machine. It saves customers the cost of purchasing multiple machines such as pop patti channel machine, pop bottom channel machine and v-shaped profile machine, and the time and energy spent on choosing machines.

Introduction of Pop Patti Channel Machine

Purpose of the pop patti channel machine:

Hat channels are often used as covering keels in ceiling systems. Omega channels can be directly fixed to the load-bearing keels with screws, or tied and fixed with wire or rope. It is very convenient to install and can be used in combination to meet customers' different ceiling or other home decoration needs. |  |

Advantages of pop patti channel machine:

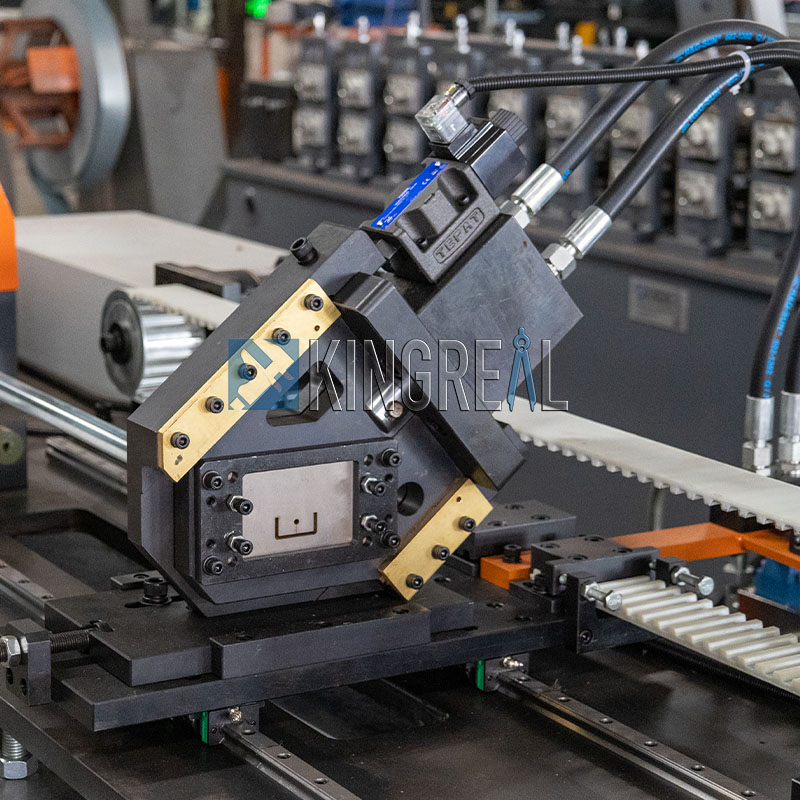

①KINGREAL CEILING MACHINERY engineers equipped this roll forming machine with an independent arch design, combining high-quality components such as electrical systems and hydraulic systems of well-known domestic and foreign brands. This high-standard configuration not only improves the durability of the pop patti channel machine, but also ensures its stability during operation. High-quality materials and precise craftsmanship enable the pop patti channel machine to maintain its excellent performance during long-term use, reducing the failure rate and maintenance costs, and providing customers with great use guarantees. |  |

② In response to the market demand for different product specifications, KINGREAL CEILING MACHINERY engineers designed two solutions: roller replacement and hanger replacement, so that this pop patti channel machine can flexibly produce finished products of different heights and widths. This design not only meets the diverse needs of customers, but also improves production efficiency. Customers can easily adjust the machine configuration according to actual needs to achieve the production of products of various specifications and optimize the production process. |  |

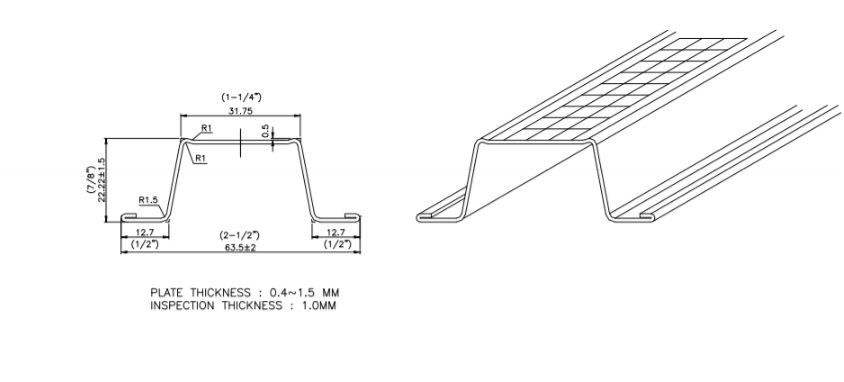

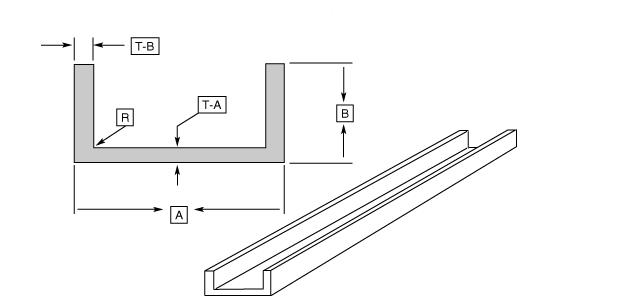

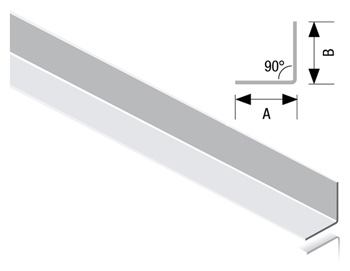

Drawings about pop patti channel:

|  |

Introduction of Pop Bottom Channel Machine

Purpose of the pop bottom channel machine:

U channel is also a common false ceiling channel, mainly used in ceiling decoration projects, often used in conjunction with partition boards, decorative keels, etc. The u channel has strong bearing capacity and stability, and is suitable for decoration and structural support with large loads. |  |

Advantages ofpop bottom channel machine:

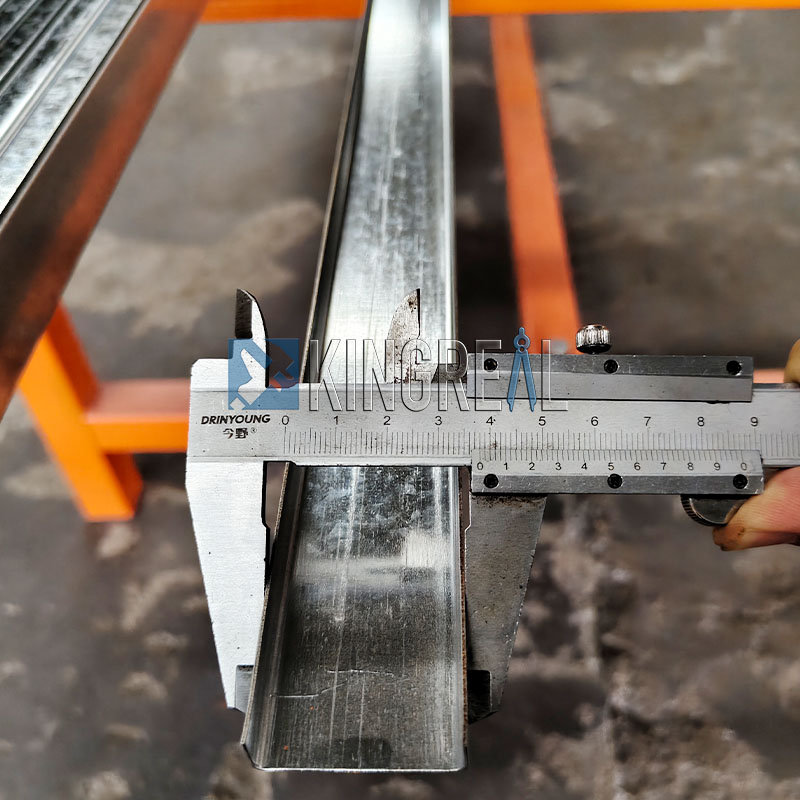

①This pop bottom channel machine is equipped with an intelligent PLC control panel. Users only need to enter the production parameters on the control panel in advance, and the pop bottom channel machine will run automatically, and the production process requires almost no human intervention. This efficient automation design greatly reduces labor costs and improves production efficiency, while also reducing errors that may be caused by human operation, ensuring product consistency and quality. |  |

②KINGREAL CEILING MACHINERY engineers equipped the cutting station with an advanced flying shear system that can quickly and accurately cut metal profiles. The system allows shearing without stopping the pop bottom channel machine during production, greatly improving work efficiency. The introduction of the flying shear system not only improves the accuracy of shearing, but also shortens the production cycle. |  |

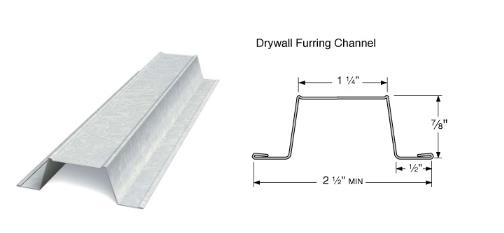

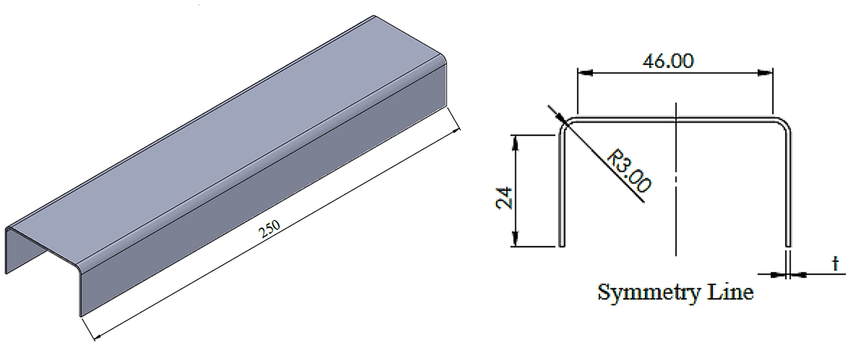

Drawings about pop bottom channel:

|  |

Introduction of V-shaped Profile Machine

Purpose of the v-shaped profile machine:

The V-shaped Profile is suspended from the main ceiling by fasteners. In addition, the cutting of the V-shaped Profile depends on the location where the user installs the ceiling. |  |

Advantages of v-shaped profile machine:

① The cutting station adopts a swing shear design. The advantage of the swing shear is that it can achieve efficient and accurate shearing operations. The swing shear can effectively reduce the energy loss during the shearing process through a unique structural design. With the use of blades made of high-hardness materials, the shearing error is controlled within ±1.0mm, ensuring the high quality standards of the finished product. |  |

②KINGREAL CEILING MACHINERY can also equip this v-shaped profile machine with a punching station to meet customers who have production needs for punching wall angles. Simply put the metal coil into the v-shaped profile machine, and the finished product with perforated v-shaped profiles can be automatically produced without the need to purchase additional equipment. This integrated design not only saves customers' investment costs, but also simplifies the production process and improves overall production efficiency. |  |

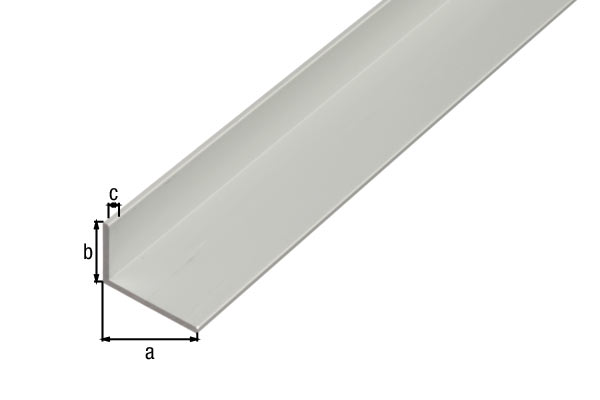

Drawings about v-shaped profile:

|  |

Application of Pop Channel Machine

The false ceiling channels produced by KINGREAL CEILING MACHINERY pop channel making machines, including u channel, omega channel and v-shaped profile, are widely used in various types of construction and interior decoration projects due to their superior performance and versatility. These profiles are becoming increasingly important in modern buildings, especially in places such as offices, hotels, schools and railway stations, where they have become key components for supporting ceilings. The light weight and high strength of the false ceiling channel enable it to effectively ensure the stability and beauty of the ceiling. |  |

Quality Assurance

The false ceiling channels produced by KINGREAL CEILING MACHINERY pop channel making machines are durable, hard and precise. The surface is smooth and burr-free. This is because the selection of raw materials is very strict before the pop channel machine is manufactured, and during the manufacturing process, KINGREAL CEILING MACHINERY has an audit team that will go to the workshop to inspect the manufactured parts. After production is completed, metal coils will also be put into the pop channel making machine for formal testing. Only pop channel machines that can meet customer production needs will be sent to customer factories.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)