What materials can metal stamping equipment process?

2025-08-17 17:00

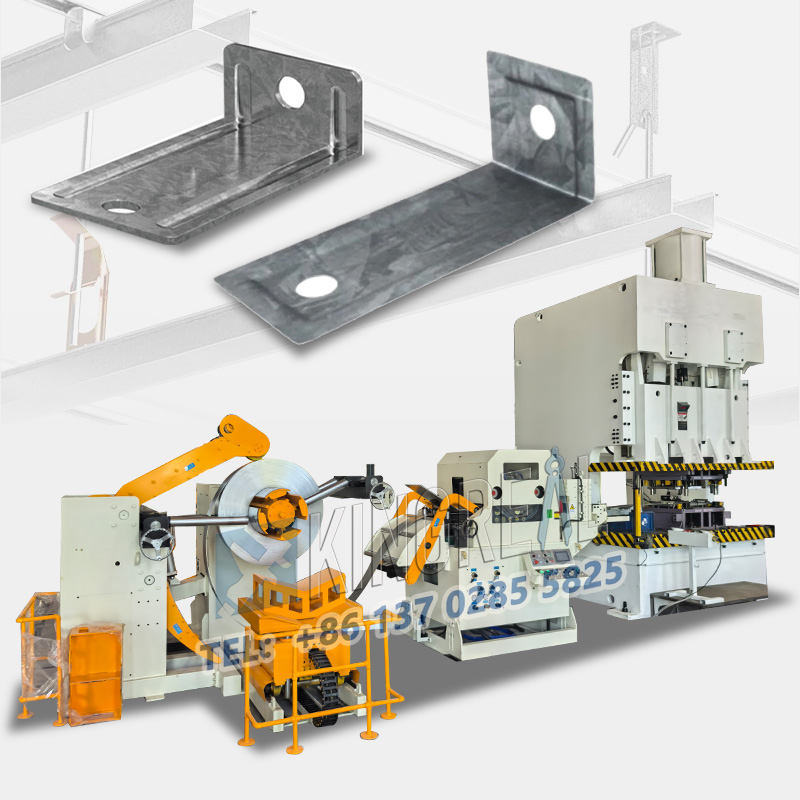

A range of metal materials may be processed into requested forms and dimensions by metal stamping equipment quickly and exactly.Knowing the kinds of materials sheet metal stamping machine users may handle is absolutely vital.

This not only guides them in choosing the appropriate fabric but also boosts product quality and manufacturing efficiency.The many materials metal stamping equipment can handle will be discussed thoroughly in this article together with advice on selecting the right one.

Sheet Metal Stamping Machine Material Processing Capabilities

Metal stamping equipment can process a wide variety of metal materials, including but not limited to:

-Mild Carbon Steel

Mild carbon steel is among the most often used materials for sheet metal stamping machines. Because of its great plasticity and flexibility, mild steel is ideal for producing complex stamped components. In industries including home appliances and automobiles, it is becoming more widely used owing to its low cost and ease of processing.

-Stainless Steel

Stainless steel is picked for its great aesthetic value and high corrosion resistance.Usually found in medical devices, cooking tools, and architectural design, metal stamping equipment may process stainless steel parts to ensure product endurance and aesthetic appeal.

-Aluminum and Aluminum Alloys

Aluminum and its alloys are a popular choice for aerospace, automotive, and electronics applications due to their lightweight and excellent formability. Sheet metal stamping machines can efficiently stamp aluminum, meeting the dual requirements of weight and strength.

-Copper and Copper Alloys

Perfect for the electronics and electrical sectors, copper and its alloys have great thermal and electrical conductivity.Copper can be exactly processed by metal stamping equipment to produce vital parts including heat sinks and electrical connectors.

-Brass

Brass is a material commonly used in valves, fittings, and decorative items. Sheet metal stamping machines can process brass, imparting its excellent strength and corrosion resistance.

-Titanium and Titanium Alloys

For their lightweight, high-temperature, and corrosion-resistant characteristics, titanium and its alloys are prized in the aeronautical, medical, and chemical sectors.Titanium can be processed with metal stamping equipment, therefore offering solutions for high-end goods.

-Galvanized Steel

Galvanized steel is widely used in the construction and appliance industries due to its excellent corrosion resistance and low cost. Sheet metal stamping machines can efficiently stamp galvanized steel to meet market demand.

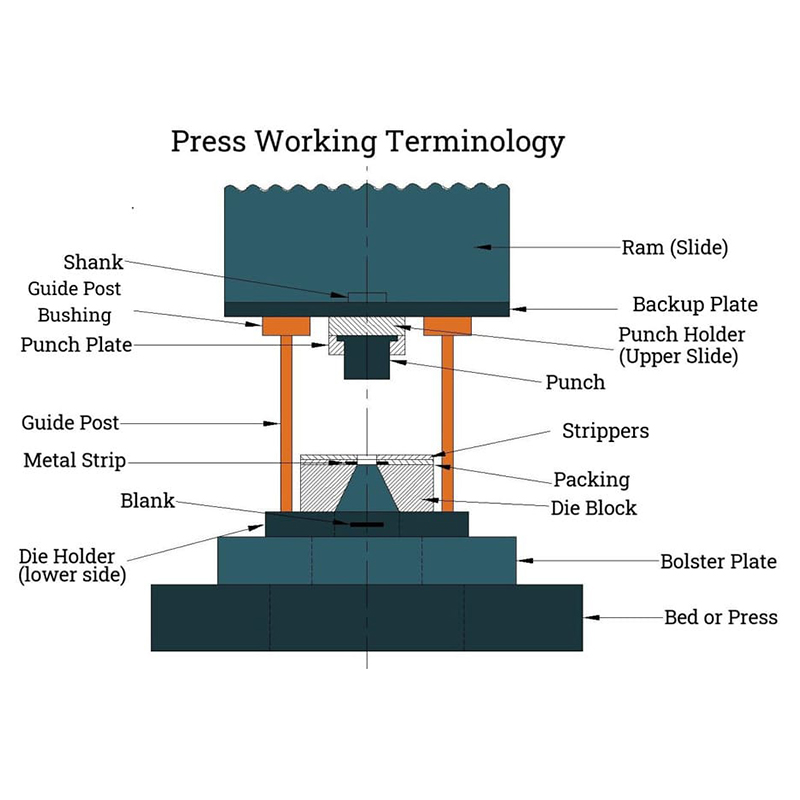

How Does a Metal Stamping Equipment Work?

The functioning principle of a sheet metal stamping machine is rather easy and effective.Flat pieces of metallic material are positioned between the upper and lower dies of a metal stamping equipment during the stamping process.The press then places considerable stress on the metal to fit it into the intended form.Cutting, bending, punching, embossing, flanging, and embossing are among stamping techniques.

KINGREAL CEILING MACHINERY engineers create and make the necessary stamping dies before the sheet metal stamping machine starts working.Using cutting-edge CAD/CAM computer applications, they produce accurate models of the dies before manufacturing them by techniques including wire cutting, grinding, and milling.This rigorous technique guarantees great quality metal components by guaranteeing the dies operate flawlessly with the metal stamping equipment. |  |

How Do You Choose Right Material for a Sheet Metal Stamping Machine?

Selecting the right material is crucial to ensuring high-quality products produced by a metal stamping equipment. Here are a few important considerations:

1. Material Mechanical Properties

Directly affecting the performance of a stamped component are its mechanical characteristics.In choosing materials, you should think about:

The strength of the material defines the stamping component's resistance to load deformation.For parts that must bear big loads, high-strength materials—such as high-strength steel or aluminum alloys—should be chosen.

Good ductility materials like mild steel and aluminum alloys are appropriate for stamping pieces with intricate shapes; while materials with poor form-ability like high-carbon steel may crack or wrinkling.

The hardness defines the amount of wear the stamping die encounters in the material.Higher hardness materials enhance component wear resistance even if they increase die wear; thus, the right hardness should be selected depending on the particular application.

2. Material Form-ability

Form-ability is an important indicator of a material's ease of processing during the stamping process. The following factors influence material form-ability:

Good plasticity materials such as mild steel and copper alloys are less prone to break while stamping and fit components with intricate shapes.

Some materials (such high-strength steel) can exhibit spring-back following stamping, therefore producing dimensional changes in the component. Therefore, material selection should take into account its spring-back qualities.

The ultimate appearance of the stamped piece depends on the surface quality of the material.Parts needing high surface quality benefit from smooth, defect-free materials like cold rolled steel.

3. Material Cost

Weigh the material price, processing cost, and scrap rate:

The cost of various materials varies greatly. Although aluminum alloys are light and ideal for weight-sensitive industries, they cost more than traditional carbon steel.

Although some materials (like stainless steel) are more expensive, their resistance to wear and corrosion can help to extend component life and reduce longrun maintenance costs.

Choosing easy to shape materials will help to reduce manufacturing costs and reduce waste.

4. Material Environment

The environment in which stamped parts will be used greatly influences the material selections.Consider the next factors:

Materials with good corrosion resistance, such as stainless steel, aluminum alloys, or galvanized steel, should be chosen in corrosive surroundings including those with humidity, acids, and alkalis.

Components operating in high-temperature circumstances call for high-temperature-resistant materials like heat-resistant steel or titanium alloys.

Parts exposed to friction—for instance gears and bearings—materials with great wear resistance like surface-hardened or high-carbon steel should be chosen.

5. Material Weld-ability and Machinability

Stamped parts sometimes need additional treatment or welding; thus, the material's machinability should be taken into account:

Materials like stainless steel and mild steel have excellent weld-ability and are suited for parts requiring welding.

Machinability: Although some materials—like titanium alloys—provide great performance, machining is challenging and calls for a thorough balancing of process viability and machining costs.

6. Material Environmental Performance

Material selection must also take environmental performance into account as environmental protection standards grow:

Materials like mild steel and aluminum alloys are easily recyclable and satisfy the demands of sustainable development.

Hazardous Substances: Some substances—such as alloys including lead and cadmium—could be hazardous for the environment and should be shun.

7. Industry Standards and Customer Requirements

Different sectors have varying material stamping demands; hence, the appropriate standards and customer specifications must be respected:

Automotive Industry: The main trend is light-weighting; commonly used materials include high-strength steel, aluminum alloys, and magnesium alloys.

Electronics Industry: Commonly used materials include copper alloys, stainless steel, and galvanized steel since surface quality and conductivity are quite stringent.

Home Appliance Industry: Appearance and corrosion resistance are key, and commonly used materials include stainless steel, galvanized steel, and aluminum alloys.

8. Material Supply and Inventory

Material supply stability and inventory management are also factors to consider when selecting materials:

Supply stability: Select materials with sufficient market supply to avoid production disruptions caused by material shortages.

Inventory Management: Rationally manage material inventory to avoid increased costs due to overstocking.

9. Testing and Validation

In actual production, it is recommended to verify material suitability through small-batch testing. The most suitable material can be determined through trial stamping, performance testing, and cost analysis.

Processing a broad spectrum of metal materials, including mild steel, stainless steel, aluminum, and copper, metal stamping equipment are absolutely necessary in the metalworking sector. Choosing the correct material not only raises product quality but also maximizes production efficiency and lowers costs.

As a sheet metal stamping machine manufacturer, KINGREAL CEILING MACHINERY is committed to providing customers with high-quality metal stamping equipment and expert material selection advice, helping them stand out in the fiercely competitive market. If you are interested in sheet metal stamping machines, please feel free to contact KINGREAL CEILING MACHINERY. KINGREAL CEILING MACHINERY will provide you with the best service and metal stamping equipment solutions.

Get the latest price? We'll respond as soon as possible(within 12 hours)