Cassette Keel Making Machine

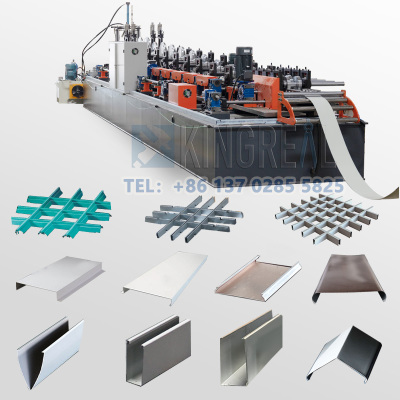

KINGREAL CEILING MACHINERY cassette keel making machine is specifically designed for continuous, high-volume production of baffle ceiling carriers and linear strip ceiling carriers.

- KINGREAL CEILING MACHINERY

Details

● KINGREAL CEILING MACHINERY Cassette Keel Making Machine

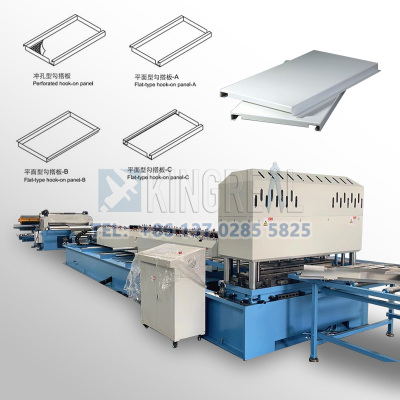

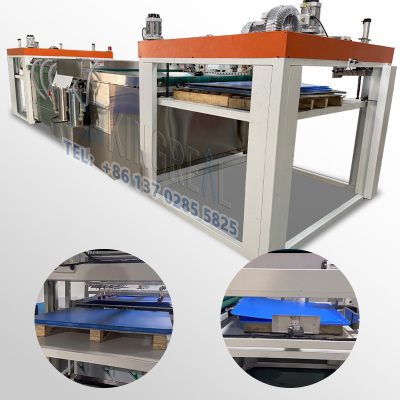

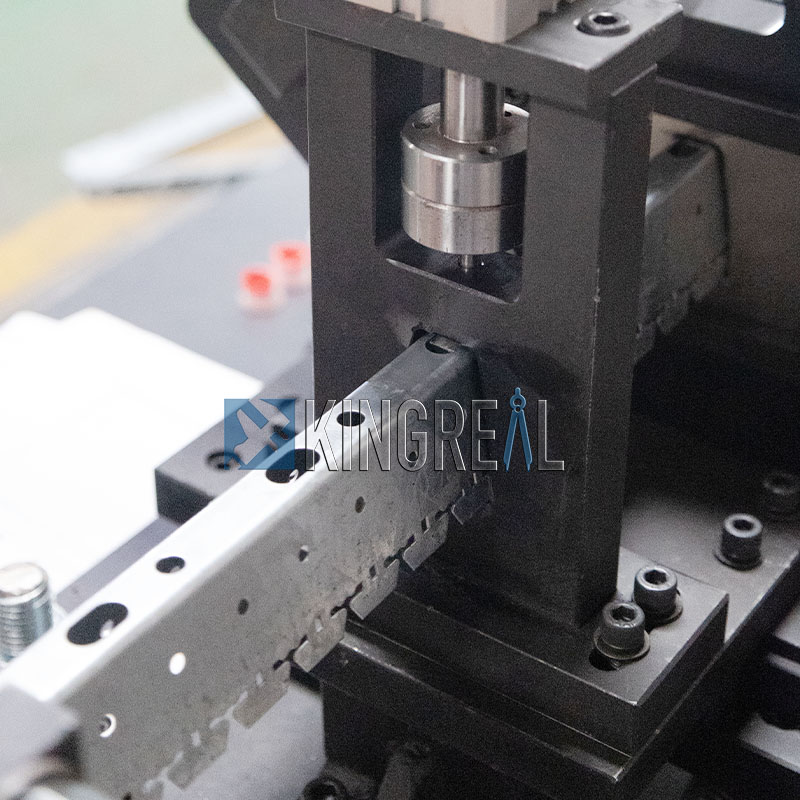

KINGREAL CEILING MACHINERY cassette keel making machine is specifically designed for continuous, high-volume production of baffle ceiling carriers and linear strip ceiling carriers. This not only improves production efficiency but also helps customers meet diverse architectural design needs. The combination of the cassette channel making machine with ◀ baffle ceiling machine and linear strip ceiling machine ▶is particularly important in suspended ceiling systems. By changing the molds, the cassette keel making machine can quickly produce different types of profiles and flexibly adjust the punching spacing to ensure perfect matching of various specifications of baffle ceilings or linear strip ceilings, bringing greater stability and aesthetics to the building. KINGREAL CEILING MACHINERY cassette channel making machine uses advanced cold rolling forming technology to process raw materials such as galvanized steel, aluminum, or color-coated steel coils into precise profiles with consistent cross-sections. This high efficiency and versatility make the cassette keel making machine highly advantageous in office building ceilings and modular construction, making it the preferred equipment for many builders. |  |

● Working Process of Cassette Keel Making Machine

2-in-1 Decoiler & Leveling Machine –> Punching Machine –> Roll Forming Machine –> Hydraulic Cutting Station –> Output

● Technical Specifications of Cassette Keel Making Machine

| Processing Material | GI coils |

| Input Width | customized |

| Formed Width | as needing |

| Processing Thickness | Standard: 0.3—0.6mm |

| Frame Style | Steel plate welded box |

| Material of Rollers | 45# steel, with heat treatment and hard chromed |

| Diameter of Shaft | 50mm |

| Production Speed | Standard: 0–25m/min(without punching); customized |

| Roller Driven | Gear Transmission |

| Cutting Model | Hydraulic Profile Cutting |

| Length Measurement | Encoder |

| Control Style | PLC |

| Operation Model | Button+Touch Screen |

| Total Power | 4+4+1.5KW; customized |

| Voltage | 380V, 50Hz, 3 phrases; or at buyer’s request |

● Advantages of Cassette Keel Making Machine

● Fully automatic high-speed, high-precision cassette channel making machine. The KINGREAL CEILING MACHINERY cassette keel making machine features a user-friendly control panel design. Operators only need to easily adjust relevant parameters for fully automatic operation. This not only reduces labor costs, requiring only one worker to supervise the production line and process profiles, but also allows the machine to operate stably for extended periods to meet the needs of mass production.

● Diverse profile production. By changing the molds, the cassette channel making machine can produce various types of cassette channels, including linear strip ceiling carriers and baffle ceiling carriers. During production, the manufactured cassette keels perfectly match different baffle ceiling and linear strip ceiling specifications, including standard 150mm, 200mm, and 300mm height baffle ceilings, as well as different models of linear strip ceilings.

● Flexible punching spacing adjustment. This bcassette channel making machine is equipped with an adjustable punching unit. By changing the punching molds, customers can produce cassette channels with different spacing according to project requirements. This flexibility makes project management smoother and improves installation convenience.

● Product Details

What is cassette keel?

Cassette keel is made of steel and is the main supporting material for baffle ceilings and linear strip ceilings. It not only effectively connects and fixes the keel but also plays a stabilizing role in the overall structure. It is fixed to the floor with screws, ensuring the ceiling's firmness.

How to use cassette keel?

Cassette light keel is usually installed in conjunction with linear strip ceilings or baffle ceilings to enhance the ceiling's strength and environmental friendliness. The following is the installation process for your reference:

-Accurately control the keel spacing: Ensure accurate spacing, otherwise installation errors will occur.

-Assembly sequence: Follow the sequence of "measurement and layout → fixing hangers → installing corner edges → installing main keel → installing secondary keel and support keel → installing decorative panels → installing trim strips and finishing strips".

-Ensure levelness: Ensure the bottom edge of the finishing strip is on the same horizontal plane to prevent the aluminum panel edges from tilting.

-Lighting and Equipment Installation: Lighting fixtures, air vents, and access panels on the ceiling should be installed with independent hangers and must not be fixed to the keel hangers.

● Complete Suspended Ceiling System Solutions

KINGREAL CEILING MACHINERY has successfully provided complete suspended ceiling system solutions to customers in many countries. In addition to providing cassette keel making machines, KINGREAL CEILING MACHINERY also offers baffle ceiling machines and linear strip ceiling machines. By using them in combination, the produced cassette channels can perfectly match baffle ceilings or linear strip ceilings, ensuring high installation accuracy. KINGREAL CEILING MACHINERY can meet various sizes and special production needs.

KINGREAL CEILING MACHINERY one-stop service

KINGREAL CEILING MACHINERY is committed to providing customers with one-stop service. From cassette keel making machine manufacturing to subsequent installation training, every step is strictly controlled to ensure customers receive the best user experience.

-Factory Visit: KINGREAL CEILING MACHINERY warmly invites customers from all over the world to visit the KINGREAL CEILING MACHINERY factory for cassette channel making machine tours. Customers can personally evaluate the cassette channel making machine's operation and inspect the quality of finished products, gaining a deeper understanding of KINGREAL CEILING MACHINERY cassette keel making machines.

-Solution Design: KINGREAL CEILING MACHINERY engineers will tailor a cassette keel making machine manufacturing solution based on the client's project requirements, ensuring the finished product perfectly matches the client's specifications. During this stage, KINGREAL CEILING MACHINERY staff will thoroughly understand the client's specific needs, including processing materials, weight, width, thickness, and production volume.

-Cassette Channel Making Machine Manufacturing: In the cassette keel making machine manufacturing stage, KINGREAL CEILING MACHINERY has a rigorous production process and a professional technical team with over 15 years of experience, ensuring high-quality cassette channel making machines.

-Cassette Keel Making Machine Inspection: After manufacturing is complete, KINGREAL CEILING MACHINERY will invite the client to the factory for cassette channel making machine testing. The cassette keel making machine will only be shipped after it meets the client's standards and receives their approval. If the client has any objections to the inspection results, KINGREAL CEILING MACHINERY engineers will immediately make adjustments to ensure the cassette channel making machine is qualified for shipment.

-Cassette Keel Making Machine Shipping and Installation Training: The KINGREAL CEILING MACHINERY team strictly controls the packaging of cassette channel making machine components, using multiple methods such as wooden crates and plastic film to ensure safe transportation. Furthermore, KINGREAL CEILING MACHINERY will share the shipping process with the client through photos or videos, and dedicated personnel will track order information. After the cassette keel making machine is delivered, KINGREAL CEILING MACHINERY professional engineers will go to the customer's site to install the cassette channel making machine and provide operation training to ensure that the customer can quickly get started and use it to achieve stable and efficient production.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)