KINGREAL CEILING MACHINERY After-sales Service

At KINGREAL CEILING MACHINERY, we are well aware of the importance of after-sales service in terms of customer satisfaction and machine performance. In order to ensure that customers can fully utilize KINGREAL CEILING MACHINERY equipment and maximize the service life of the machine, KINGREAL CEILING MACHINERY team of engineers provides detailed after-sales service. Whether in Saudi Arabia, Russia, Italy, Mexico, Canada, the United States and other places, KINGREAL CEILING MACHINERY engineers actively go to carry out machine installation, operation training, commissioning and maintenance.

Composition of KINGREAL CEILING MACHINERY Engineer Team

KINGREAL CEILING MACHINERY team of engineers is composed of a group of experienced and skilled professionals. They not only have solid theoretical knowledge, but also have rich practical experience, and are able to master the installation and commissioning of all KINGREAL CEILING MACHINERY equipment. These engineers have rich working experience in different countries and regions, and can understand and respond to various market needs to ensure that every customer can enjoy high-quality service.

Diverse Machine Expertise

KINGREAL CEILING MACHINERY engineers are proficient in the operation and maintenance of a wide range of machines, including:

This wide range of expertise allows KINGREAL CEILING MACHINERY engineers to provide customers with targeted solutions to ensure the efficient operation of the machine.

Core content of after-sales service

1. Machine installation and commissioning

After the customer purchases the machine, KINGREAL CEILING MACHINERY engineers will personally go to the customer site to install and commission the equipment. This process is crucial because correct installation ensures the normal operation of the machine.

On-site installation: Engineers will perform precise installation based on the characteristics of the equipment and the customer's production environment. This includes not only the mechanical installation of the equipment, but also electrical connections and software configuration.

Commissioning process: After the installation is completed, the engineer will conduct a comprehensive commissioning of the equipment to ensure that all functions of the machine are operating normally. This process may include adjusting the feed speed, checking the cutting accuracy, and testing the overall efficiency of the production line.

2. Operation training

After the equipment is installed and debugged, KINGREAL CEILING MACHINERY engineers will provide systematic training for the customer's operators. The training content includes:

Operation manual: Engineers will provide detailed operation manuals to help workers understand the various functions and operation steps of the equipment.

Common problem solving: Engineers will inform workers in advance of common problems that may be encountered during the production process and provide corresponding solutions to ensure that workers can respond quickly when they encounter problems.

Daily maintenance guidance: The training also includes daily maintenance skills to help customers keep the equipment in the best condition and extend its service life.

Engineers' significant capabilities

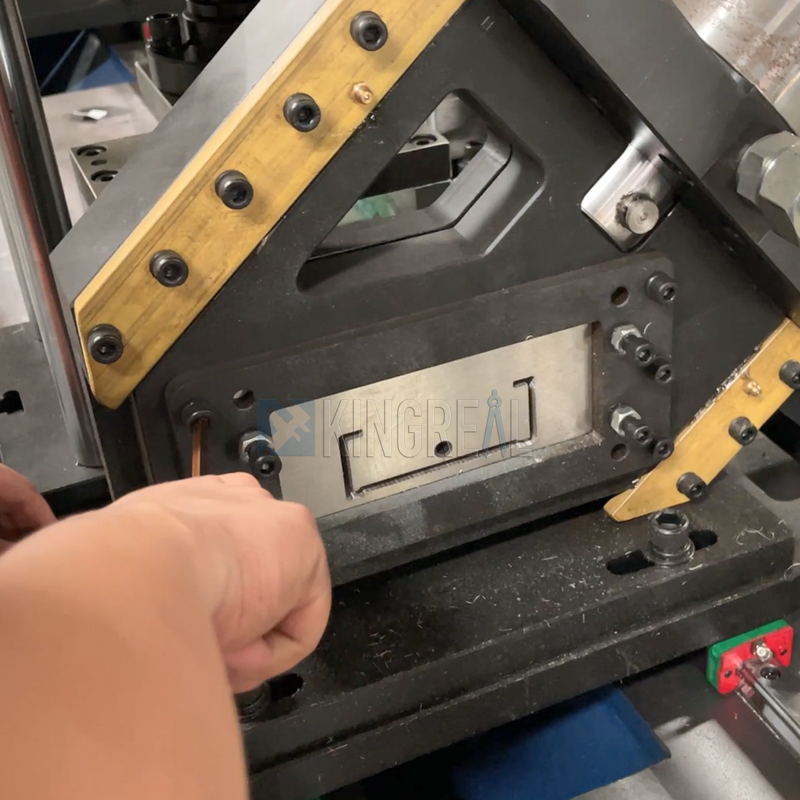

1.Manufacturing and replacement of punching dies

In terms of sheet metal perforation machines, KINGREAL CEILING MACHINERY engineers are not only able to replace punching dies, but also have the ability to manufacture dies. This ability gives them a deeper understanding of the installation and use of punching dies.

Customization of customer needs: The common punching die apertures on the market are 1.8mm and 2.5mm. Recently, in response to the special production needs of customers in Greece and Morocco, KINGREAL CEILING MACHINERY engineers have successfully designed and manufactured sheet metal perforation machines capable of punching out 1.0mm and 1.5mm micro-punching apertures. This innovation solves the challenges faced by customers in the production process and improves their production capabilities.

Global installation experience: KINGREAL CEILING MACHINERY engineers have also traveled to Brazil, the United Arab Emirates, Turkey, Saudi Arabia and other countries to install and debug punching dies to ensure that customers can fully utilize the advantages of this sheet metal perforation machine.

2.Replacement of hangers and blades of roll forming machines

KINGREAL CEILING MACHINERY engineers have also performed well in guiding customers to replace the hangers and blades of roll forming machines.

Hanger replacement: For example, KINGREAL CEILING MACHINERY ceiling t bar machine can produce different sizes of ceiling t grids by replacing the hanger. In addition, the 3 in 1 false ceiling channel machine can produce U-shaped, L-shaped and Omega profiles by replacing the hanger. This flexibility not only improves the efficiency of false ceiling channel machine use, but also meets the diverse production needs of customers.

Blade replacement guidance: Engineers will provide detailed guidance to customers on how to correctly replace blades and ensure that the installation of blades meets safety standards. This training not only improves customers' operating skills, but also reduces equipment failures caused by improper blade replacement.

3.Machine installation and guidance

KINGREAL CEILING MACHINERY engineers also have rich experience in installing machines and providing guidance.

On-site installation: For customers who purchase metal ceiling machines, baffle ceiling machines, u channel machines, wall angle profile machines, omega channel machines, grilyato ceiling machines, sheet metal perforation machines and other equipment, KINGREAL CEILING MACHINERY engineers will personally go to the site for installation. This process ensures that the equipment can be put into use in the best condition.

Operation guidance: After the installation is completed, KINGREAL CEILING MACHINERY engineers will provide detailed training to operators and provide operation manuals to inform them in advance of situations and solutions that they may encounter during the production process. In addition, engineers will also teach customers how to perform daily maintenance to ensure the long-term operation of the equipment.

Successful Cases of KINGREAL CEILING MACHINERY Engineers

At KINGREAL CEILING MACHINERY, engineers have successfully helped multiple international customers install and debug machines, and have been highly recognized by customers.

Case 1: Metal ceiling production line in Saudi Arabia In a project in Saudi Arabia, engineers from KINGREAL CEILING MACHINERY installed a brand new metal ceiling production line for the customer. During the installation process, the engineers not only carried out precise installation of the metal ceiling machine, but also debugged it according to the production needs of the customer. Through close communication with the customer, the engineers adjusted the machine parameters in a timely manner to ensure that the production efficiency reached the best state. After the installation, the engineers also conducted systematic training for the operators to help them quickly master the operation skills of the metal ceiling machine. |  |

Case 2: Perforated metal machine in Brazil In a manufacturing company in Brazil, engineers from KINGREAL CEILING MACHINERY installed a perforated metal machine for the customer. And taught the Brazilian workers in detail how to correctly replace the punching die to achieve a sheet metal perforation machine to produce perforated metal plates with different hole shapes and diameters. The meticulous teaching allowed the workers to quickly master the correct operation of the sheet metal perforation machine, greatly improving the production capacity of the customer and gaining high praise from the customer. |  |

Case 3: Baffle ceiling machine in Italy In Italy, KINGREAL CEILING MACHINERY engineers installed a baffle ceiling machine for a customer. After the installation, the engineer not only provided operation instructions, but also emphasized the importance of daily maintenance. Through training, the customer's operators mastered the correct maintenance skills, ensuring the stability and efficiency of the baffle ceiling machine in subsequent production. |  |

Get the latest price? We'll respond as soon as possible(within 12 hours)