Perforated Machine For Metal Acoustic Wall Panel

KINGREAL CEILING MACHINERY can supply the Metal Sheet Perforated Machine For Metal Acoustic Wall Panel. The metal sheet perforated machine can perforated metal coil or sheet with high precision. The metal perforated machine can be equipped with a recoiler to rewind the perforated coils and send them to the next process.

- KINGREAL CEILING MACHINERY

Details

Video About Metal Sheet Perforated Machine

Description Of Perforated Machine For Metal Acoustic Wall Panel

KINGREAL CEILING MACHINERY Metal Sheet Perforated Machine For Metal Acoustic Wall Panel is used for perforating different materials metal coil or panel (such as aluminum, iron, and stainless steel, etc) with high speed and high precision for produce the acoustic wall panel, which hole types and specification are adjustable. Perforated metal coil is widely used in industrial. For example,baguette pan, metal filter, acoustic wall panel before roll forming, the raw metal coil must be perforated. To meet the production needs of perforated - rewind, KINGREAL CEILING MACHINERY provide a complete metal perforated machine solution, the metal perforation line is equipped with a rewinder, which can help you rewind the perforated coil and send to the roll forming process easily. Common hole types: round hole, long round hole, square hole, triangle hole, diamond hole, hexagonal hole, crossed hole... (If you need other hole types, please send the drawing to KINGREAL CEILING MACHINERY. Engineers will customize personalized punching molds according to the actual situation of the customer.) |  |

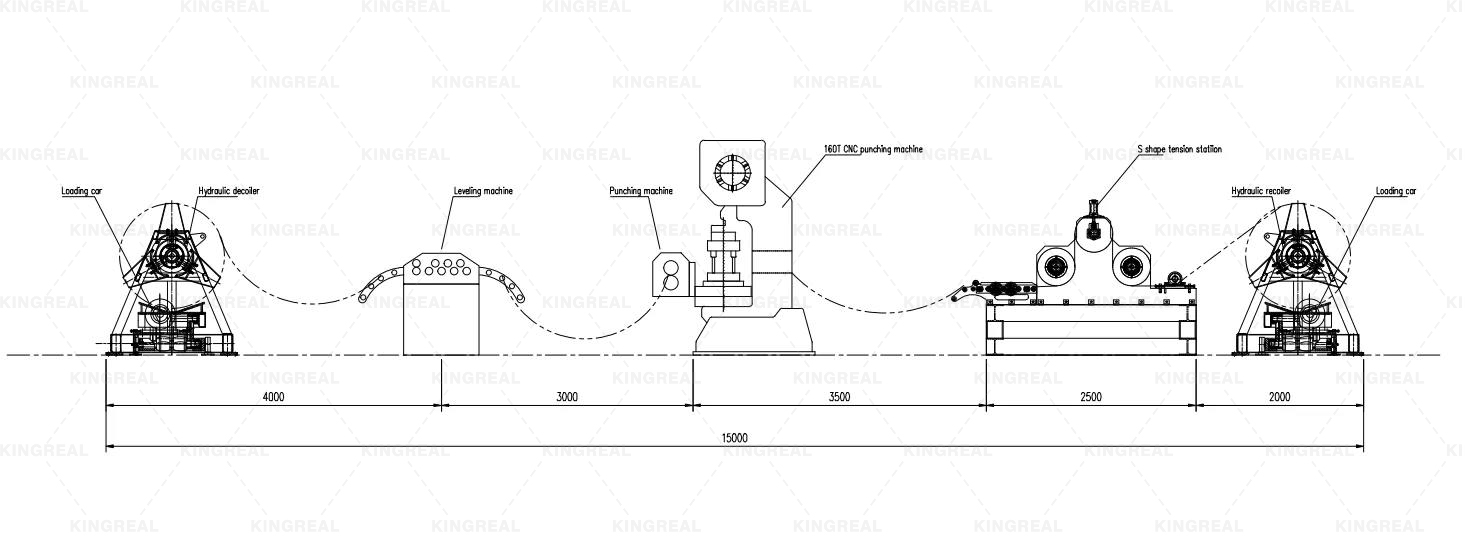

Working Process About Metal Perforated Machine

Loading coil - Decoiler - High Precision Straightener - Punch Press Machine - Tension Staition- Recoiler/Cutting Station

Technical Specification of Metal Sheet Perforated Machine

| Capacity | 1250kN |

| Nominal Stroke | 3mm |

| Slide Stroke | 20mm |

| Working Speed | 100-180 SPM |

| Max. Die Height | 420mm |

| Die Height Adjustment | 50mm |

| Main Motor Power | 18.5KW |

| Air Pressure | 0.5mm |

Application About Acoustic Wall Panel

★Recording Studios: For clear sound recording without interference from echoes.

★Auditoriums and Classrooms: To ensure clear communication and reduce noise distractions.

★Offices: To create a conducive working environment by controlling sound levels.

★Commercial Buildings: To enhance the overall acoustic quality of the space for comfort and functionality.

These panels are a practical solution for managing acoustics in various environments, contributing to both the functionality and aesthetics of a space. Besides, KINGREAL CEILING MACHINERY Metal Sheet Perforated Machine is literally the best choice for producing metal acoustic wall panel.

Advantage About Metal Perforated Machine

01 Customized metal perforated machine manufacturing solution

KINGREAL CEILING MACHINERY can customize metal sheet perforated machine manufacturing solutions according to customer needs. The metal sheet perforated machine can be equipped with a metal sheet cleaning machine. After the punched coil is accurately cut, it will be sent to the metal sheet cleaning machine to clean the oil on its surface.

02 High-precision cutting metal sheet perforated machine

The shearing station of this metal sheet perforated machine is equipped with a high-hardness blade, so the cutting of the metal coil is more accurate, consistent, and burr-free. And through the PLC control panel, customers can easily realize the production of perforated plates of different specifications on the metal sheet perforated machine.

03 Multiple punch patterns choice for metal perforated machine

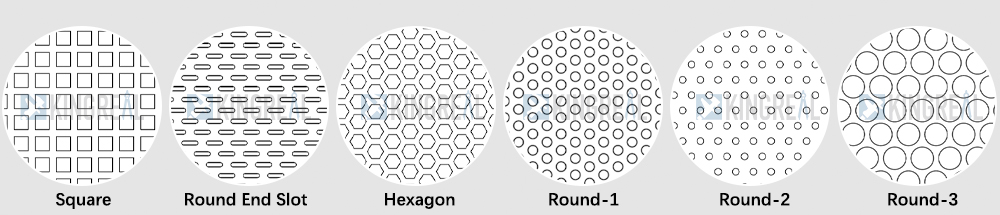

KINGREAL CEILING MACHINERY metal perforated machine adopts pneumatic brake system makes the perforation more accurate and stable. And the hole types, feed material and apertures can be chosen. The metal hole punch press can punch the coil or plate into round holes, square holes, hexagonal holes, and other hole shapes.

The raw material can be aluminum sheet, galvanized steel sheet, stainless steel sheet, and etc.. You just need to set the parameters on the electronic control system than the Metal Sheet Perforated Machine can punch automatically.

Application About Perforated Sheet

Metal sheet perforation lines can be used in various industries. KINGREAL CEILING MACHINERY has designed three kinds of metal sheet perforated machines according to different application fields.

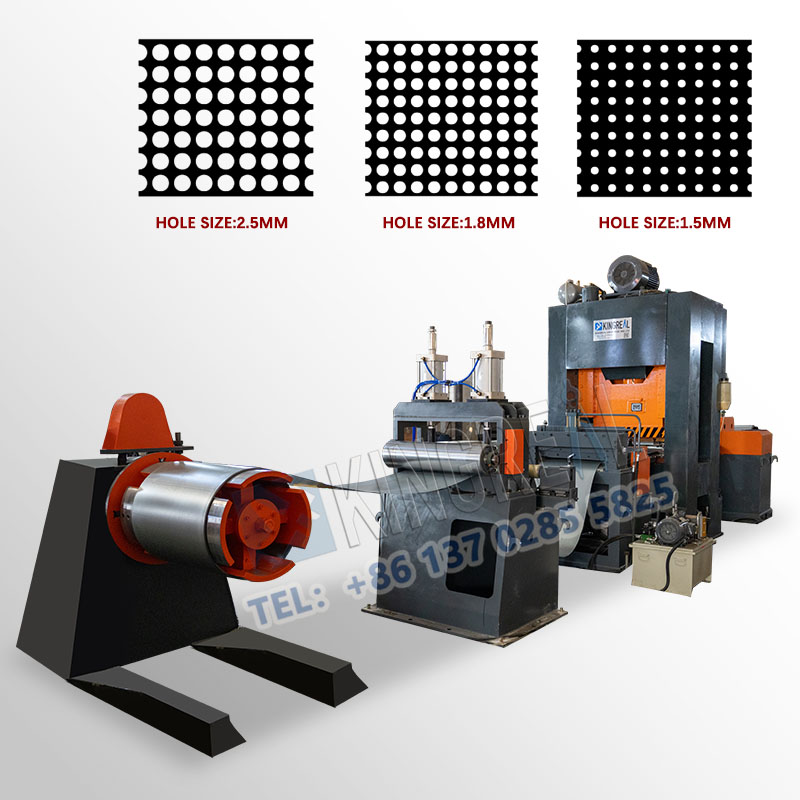

★Coil to coil perforation lines -- The metal perforation line is equipped with a recoiler. After the metal perforated sheet is made, it will be automatically wound for subsequent transportation and secondary processing.

Application areas: filters, radiator covers, refrigerator liner, electronic equipment shell, grid-shaped protective cover, screen, metal furniture, bread tray, etc.

★Metal sheet perforation lines -- The metal sheet perforated machine is equipped with a shearing station. After the metal perforated sheet is made, it will be cut according to the customer's preset length for subsequent processing.

Application areas: wall panels, motorcycle parts, solar panel brackets, decorative screens, etc.

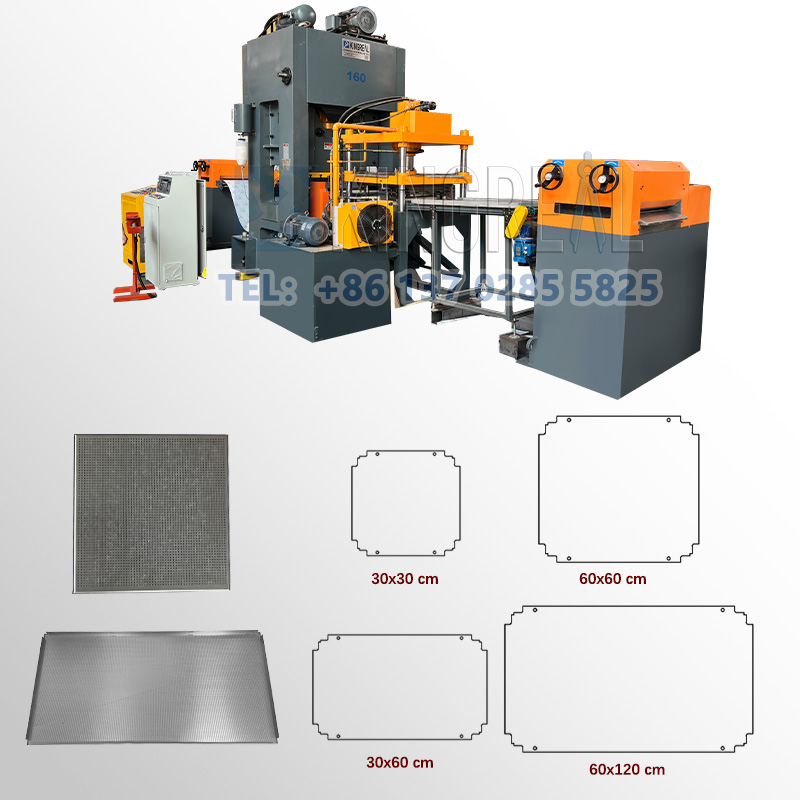

★Metal ceiling tile perforation line--Used with the metal ceiling tile production line, a complete perforated ceiling tile can be produced.

Application areas: 300x300mm, 600x600mm, 600x1200mm and other sizes, clip in metal ceiling tile, lay in metal ceiling tile, tegular metal ceiling tile and other sizes of perforated ceilings.

Hole Drawings

KINGREAL CEILING MACHINERY's metal sheet perforated machines can punch out holes with high consistency and accurate dimensions. After the metal sheet perforation line is manufactured, KINGREAL CEILING MACHINERY's professional staff will test the machine by first putting the metal raw materials into the metal perforation line for testing. During this process, the perforated sheets will be strictly tested to ensure that the hole shape that meets the customer's needs can be produced, and the surface will be checked for smoothness and burr-free. Only metal sheet perforated machines that have been strictly tested and can stably produce high-quality products will be sent to the customer's factory.

FAQ About Metal Sheet Perforated Machine

1. How to use metal sheet perforated machine?

2. What's a perforated metal sheet making machine?

3. How to perforate sheet metal by steel perforated machine?

4. How to choose a metal perforated making machine?

5. How do you perforate metal sheets?

After Sale Service About Metal Sheet Perforated Machine

In addition to providing customers with high-quality metal perforated machines, KINGREAL CEILING MACHINERY is also committed to providing detailed metal sheet perforated machine installation services to ensure that customers can use the equipment smoothly and maximize their production efficiency. The following is an important project last year, in which KINGREAL CEILING MACHINERY engineers traveled to the Brazilian customer's factory to conduct comprehensive metal sheet perforated machine assembly, machine inspection and operation guidance.

Assembly Process of Metal Perforated Machine

During the assembly stage, KINGREAL CEILING MACHINERY engineers worked closely with Brazilian workers to first unpack each component of the metal sheet perforated machine. After confirming that the surface condition of all components was good, the engineers used a forklift to carefully place the components in the factory, ready to connect them into a complete metal sheet perforated machine.

After assembly, the engineers will conduct a preliminary inspection of the entire metal sheet perforated machine to ensure that all connections and installations meet standards. This meticulous preliminary preparation lays a good foundation for subsequent metal perforated machine inspections.

Metal Perforated Machine Inspection

Once the metal sheet perforated machine is installed, KINGREAL CEILING MACHINERY engineers begin to put in metal coils for performance testing. The main test contents include:

Performance evaluation: confirm whether the performance of the metal sheet perforated machine can meet the requirements of the design plan. This includes observing and recording the operating conditions of each part of the metal sheet perforated machine.

Precision test: test the accuracy and consistency of punching to ensure that the products produced meet the customer's specifications.

This systematic testing process not only ensures the normal operation of the metal perforated machine, but also provides confidence for the subsequent production of Brazilian customers.

Operation Guidance of Metal Sheet Perforated Machine

After confirming that the metal sheet perforated machine can run stably, KINGREAL CEILING MACHINERY engineers began to train Brazilian workers on machine operation. This training covers many aspects, including:

Machine start and stop: how to properly start and stop the metal perforated machine to ensure the safety of operation.

Production speed adjustment: guide workers on how to adjust the production speed of the metal sheet perforated machine according to production needs, and adjust other key production parameters to achieve optimal production efficiency.

Mold replacement: KINGREAL CEILING MACHINERY engineers gave detailed instructions on how to replace the punching mold to ensure that workers can quickly master this key operation.

In addition, the engineer also shared some tips for daily maintenance of the metal perforated machine, such as regularly checking the lubrication of the metal sheet perforated machine and keeping the equipment clean. These practical suggestions can not only extend the service life of the metal perforated machine, but also reduce the chance of failure.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)