How to use omega channel machine?

2025-05-11 17:00

Video About Omega Channel Machine

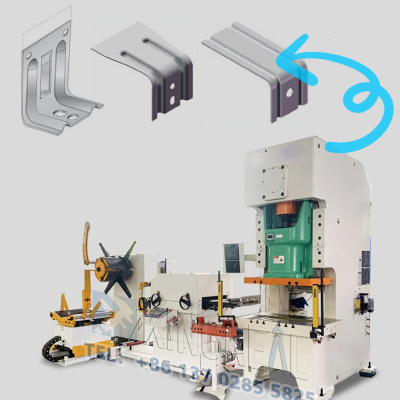

Introduction to Omega Channel Machine

The omega channel machine is designed for manufacturing omega channel. It is mainly used for the production of light or lightweight steel structure building frames, and can continuously and automatically produce omega channels from galvanized steel. As the main components of lightweight building steel roof trusses, these channels play an important role in modern buildings. In this article, KINGREAL CEILING MACHINERY will introduce the advantages, workflow and usage of the omega channel machine in detail to help customers use this equipment effectively.

Advantages of Furring Channel Machine

(1) PLC control system for furring channel machine

The furring channel machine is equipped with an advanced PLC control system, which makes the operation process very simple. The operator can easily start and stop the omega channel machine by simply entering the relevant parameters through the touch screen. This intelligent control system not only improves production efficiency, but also reduces the possibility of human error. The operator can monitor various data in the production process in real time to ensure the smoothness of the production process.

The design of the PLC system also makes the furring channel machine occupy less space and is suitable for various plant layouts. This space optimization design saves valuable production space for enterprises, especially in factories with limited area. In addition, the flexibility and programmability of the PLC system allow users to quickly adjust according to different production needs to adapt to market changes.

By reducing the complexity of operation, the PLC control system greatly reduces the requirements for the operator's professional skills, so that the company's costs in personnel training and management are also controlled. The efficient control system is one of the important reasons why the omega channel machine stands out in the fierce market competition.

(2) High efficiency and low cost

Compared with traditional production methods, the furring channel machine has higher production efficiency. It can complete a large number of keel production in a short time, greatly shortening the production cycle. This efficient production capacity enables enterprises to respond quickly to market demand, improve the timeliness of order delivery, and reduce inventory pressure.

The efficiency of the omega channel machine is not only reflected in the production speed, but also in its ability to continuously automate production. This means that the omega channel machine can continuously complete production tasks during operation, reducing downtime and manual intervention. This advantage enables enterprises to maintain an efficient production rhythm when carrying out large-scale production.

Despite its excellent performance, the production cost is relatively low. This makes the furring channel machine the preferred equipment for many construction companies and manufacturers. While reducing production costs, enterprises can still maintain high product quality, thereby achieving higher profits.

(3) Superior performance and low cost

The omega channel machine has excellent performance and can stably produce high-quality furring channels. These channels are precisely roll-formed and have good strength and toughness, which can meet various needs of building use. High-quality omega channels not only improve the overall structural safety of the building, but also improve the aesthetics of the building to a certain extent.

In addition, the design and material selection of the furring channel also make it have superior adaptability during the construction process. Whether used in different climatic conditions or in different construction environments, the furring channel can maintain good performance. This adaptability makes the omega channel have a wider application prospect in the market.

Due to its efficient production capacity and low operating costs, enterprises can achieve higher profits while ensuring quality. The economy of the furring channel machine makes it an ideal choice for many small and medium-sized enterprises, helping them to occupy a place in the market competition.

Main Components of Omega Channel Machine

The workflow of the furring channel machine mainly includes the following links:

| Decoiler: | The main function of the decoiler is to unwind the coil and feed it into the roll forming machine. It ensures the smooth supply of materials and prepares for subsequent processing. |

| Roll forming machine: | In the roll forming machine, the galvanized steel is roll-formed through a series of rollers to gradually form the shape of the omega channel. This process is the core link of the entire omega channel machine and requires the furring channel machine to have high precision and stability. |

| Shearing station: | The shearing station is responsible for cutting the formed omega channel according to the set length to ensure that the size of each channel meets the customer's requirements. |

| Discharging station: | The furring channel after shearing will be automatically sent out through the discharging station for subsequent packaging and transportation. |

Ways of Using Omega Channel Machine

The process of using the furring channel machine needs to follow certain steps to ensure the smooth progress of production and the stability of product quality. The following is a detailed method for using the omega channel machine:

1

Equipment installation and debugging

Before starting to use the furring channel machine, you first need to install and debug the equipment. Make sure that all parts are installed in place, connect the power supply and air source, and conduct a preliminary inspection of the omega channel machine. During the debugging process, it is necessary to ensure that the decoiler, roll forming machine and shearing station work smoothly to avoid jamming or failure during the production process.

2

Material preparation

Select galvanized steel that meets the production requirements and ensure that its thickness and width meet the design standards. Unwind the coil on the decoiler and ensure that it is in good condition to avoid problems during the production process.

3

Set production parameters

According to the production plan, use the PLC control system to enter the relevant production parameters. This includes the length, width, thickness of the false channel, and production speed. Make sure that these parameters match the actual production needs to improve production efficiency.

4

Start production

After confirming that all settings are correct, start the furring channel machine. Observe the operating status of the omega channel machine, ensure that the various parts work together, and pay attention to monitoring possible abnormalities during the production process.

5

Quality Control

During the production process, check the quality of the finished product regularly. Ensure that the size, shape and strength of each omega channel meet the standard requirements. If problems are found, adjust the production parameters or perform furring channel machine maintenance in time.

6

Daily Maintenance

After use, clean and maintain the omega channel machine regularly. This includes cleaning the surface of the furring channel machine, lubricating moving parts, and checking the electrical system. Through regular maintenance, the service life of the furring channel machine can be extended and its long-term and efficient operation can be ensured.

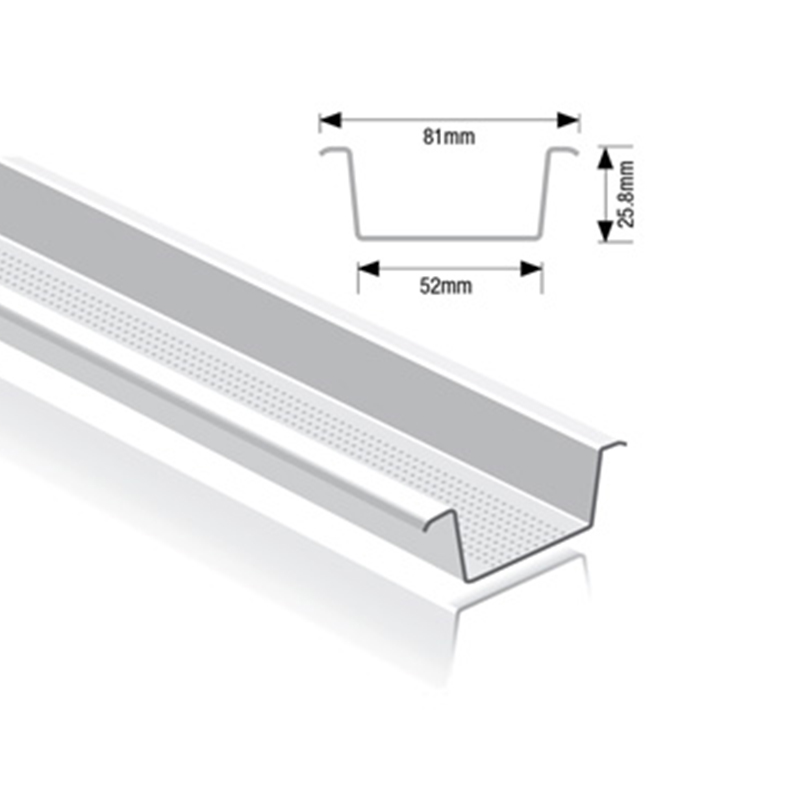

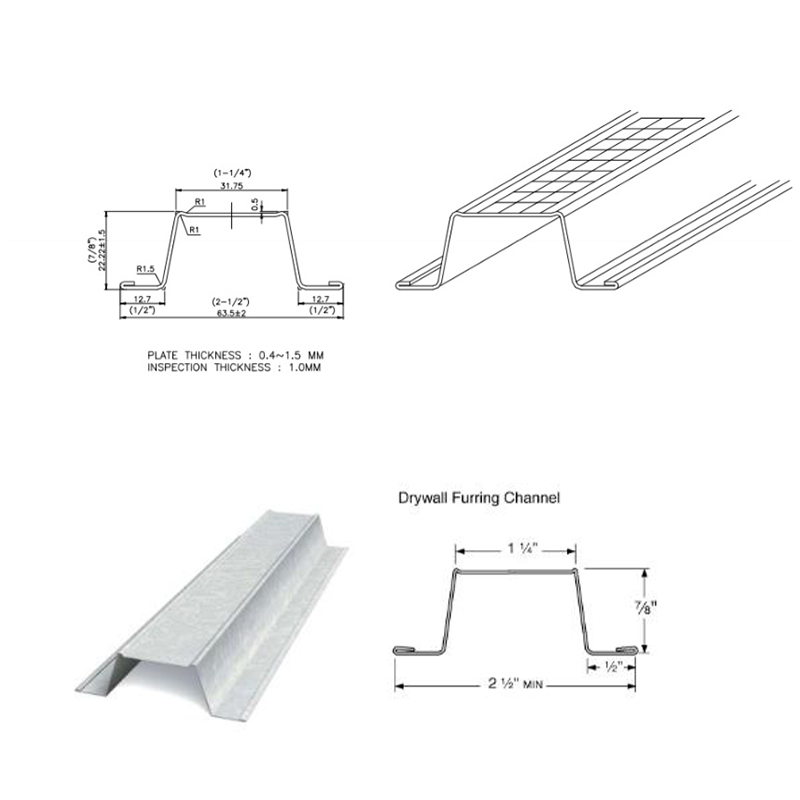

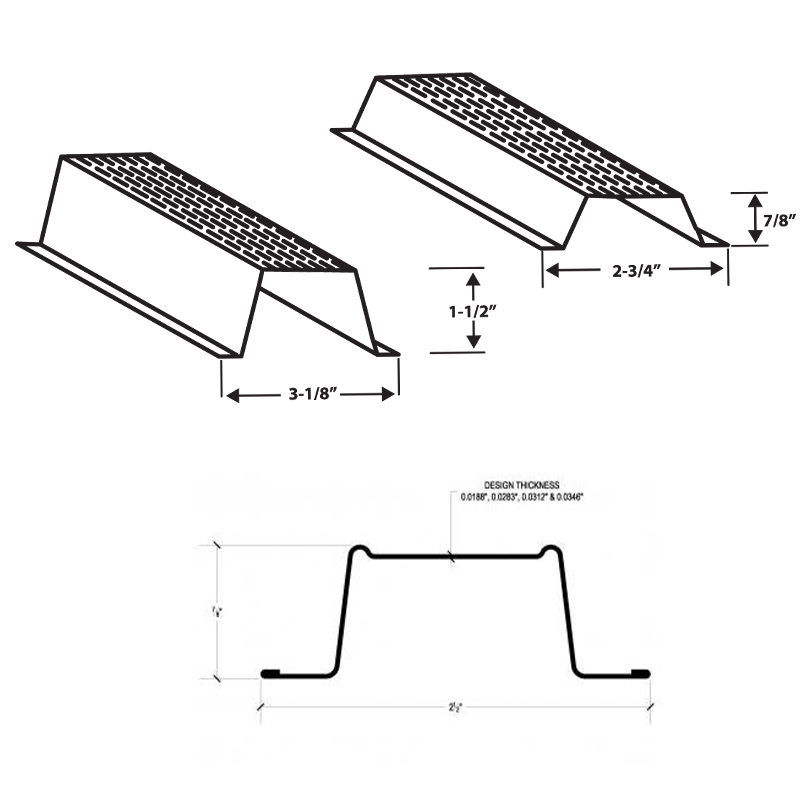

Drawing About Furring Channel Machine

Tags: furring channel machine, omega channel machine, metal ceiling channel machine, false ceiling channel machine, main ceiling channel machine

Get the latest price? We'll respond as soon as possible(within 12 hours)