What is a metal ceiling tile production line used for?

2025-08-11 17:00

A metal ceiling tile production line is specifically designed to process various metal raw materials into metal ceiling panels of various specifications and types.

Often referred to as a metal ceiling machine, drop ceiling panel making machine, suspended ceiling panel making machine, or false ceiling tile making machine, it plays a vital role in the construction and interior decoration industries.

With the increasing market demand for metal ceiling panels, metal ceiling tile making machines are becoming increasingly popular, becoming indispensable equipment for many manufacturers.

1/ Working Process of Metal Ceiling Tile Production Line

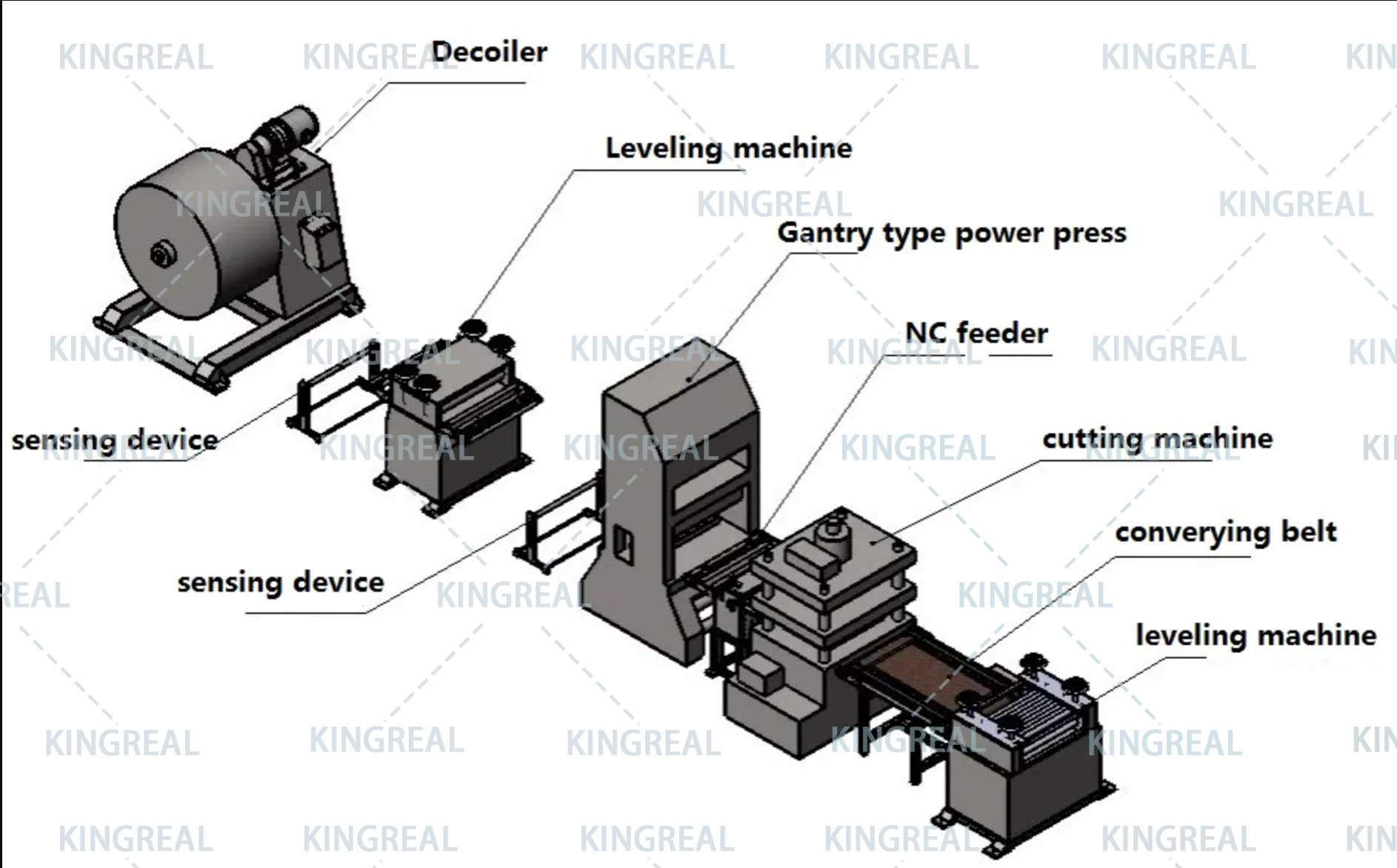

Hydraulic Decoiler -- Precision Straightener -- Punching Machine -- Servo Feeding Machine -- Notching and Shearing Press -- 2nd Precision Straightener -- Flipping Machine -- Automatic Tile Feeding Machine -- Auto Bending Forming Machine

2/ Metal Ceiling Tile Production Line Manufacturing Solutions

To meet the diverse production needs of our customers, KINGREAL CEILING MACHINERY offers a variety of metal ceiling machine solutions.

These metal ceiling production line solutions meet diverse customer requirements in terms of price, specifications, configuration, performance, and processing materials.

The following are some of the metal ceiling machine's featured solutions:

(1) According to different specifications of the metal ceiling tile:

30x30cm metal ceiling tile production line,

60x60cm metal ceiling tile production line,

60x120cm metal ceiling tile production line.

These three specifications are the most common metal ceiling tile sizes on the market.

In addition, KINGREAL CEILING MACHINERY can also provide metal ceiling machines for 30x60cm, 30x120cm, etc. By replacing the mold, customers can use the same metal ceiling tile production line to produce metal ceiling tiles of different sizes, greatly improving production flexibility and efficiency.

(2) According to different types of metal ceiling tiles:

Clip in metal ceiling tile making machine,

Lay in metal ceiling tile making machine,

Lay on metal ceiling tile making machine,

Tegular metal ceiling tile making machine.

Among the Lay in metal ceiling tile production lines, Lay in T24 and Lay in T15 are the two most popular types of metal ceiling panels.

KINGREAL CEILING MACHINERY metal ceiling tile making machines can easily produce these two types of metal ceiling panels, and by replacing the mold, it can achieve the production of clip in ceiling tiles and lay in ceiling tiles, further expanding the product line.

(3) According to the degree of automation of metal ceiling production line

Semi-automatic metal ceiling tile making machine,

Fully-automatic metal ceiling tile making machine.

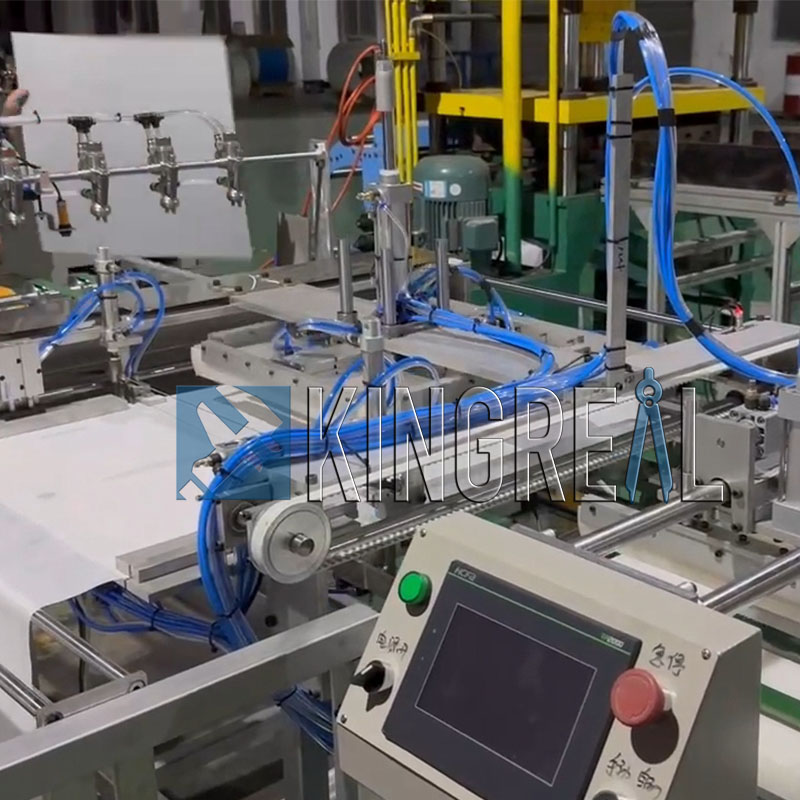

Compared to the semi-automatic metal ceiling production line, the fully-automatic metal ceiling machine has additional components such as auto bending forming press, automatic tiles feeding machine, and tiles flipping machine.

These components greatly improve production efficiency and ensure production quality and precision. Customers only need to set the production parameters on the control panel, and the metal ceiling tile production line will run automatically.

For customers who purchase semi-automatic metal ceiling tile making machines, KINGREAL CEILING MACHINERY also provides upgrade solutions.

If the customer's production scale expands in the future, KINGREAL CEILING MACHINERY can help customers upgrade the semi-automatic metal ceiling tile production line to a fully-automatic metal ceiling tile making machine.

3/ More Matching Machines for Metal Ceiling Tile Production Lines

In order to further improve the function and production efficiency of the metal ceiling tile making machine, KINGREAL CEILING MACHINERY also provides some supporting machines that can work together with the metal ceiling tile production line to improve the overall production capacity.

(1)Metal ceiling tile perforation line

If the customer needs to produce a perforated ceiling tile to improve the sound insulation effect, KINGREAL CEILING MACHINERY can equip the metal ceiling tile making machine with a metal ceiling tile perforation line.

The metal ceiling production line and the metal ceiling tile perforation line are used together to produce high-precision perforated ceiling panels, meeting the market's dual needs for sound insulation and aesthetics.

(2)Acoustic fleece sticking machine

For customers with higher sound insulation requirements for perforated ceiling tiles, KINGREAL CEILING MACHINERY offers acoustic fleece sticking machine solutions.

After production, the ceiling panels are conveyed to the acoustic fleece sticking machine for automatic applicator application, eliminating the need for manual intervention and significantly improving production efficiency.

(3)Metal sheet cleaning machine

During the metal ceiling tile production process, finished products often become contaminated with oil or dust.

KINGREAL CEILING MACHINERY metal sheet cleaning machine integrates production and cleaning, ensuring that finished metal ceiling panels remain pristine before shipment, eliminating the need for time-consuming post-processing.

Metal ceiling tile making machines are not only indispensable equipment in modern architecture and interior decoration, but also crucial tools for meeting market demands.

With the diversification of customer needs, KINGREAL CEILING MACHINERY offers a wide range of metal ceiling production line solutions, ensuring every customer finds the right line.

Whether in terms of specifications, types, or degree of automation, metal ceiling tile making machines can flexibly meet various challenges, helping customers achieve efficient and precise production goals.

By integrating with other supporting machines, the functionality of metal ceiling production lines is further enhanced, enabling customers to stand out in the fiercely competitive market.

Get the latest price? We'll respond as soon as possible(within 12 hours)