Products Lists

1. What is Metal Ceiling Machine?

Metal ceiling machines are primarily used for processing metal coils, and their application is becoming increasingly widespread, especially in the construction industry. The workflow of such machines typically involves several key steps. First, the metal coil is fed into a decoiler, where the material is unwound to facilitate subsequent processing. After uncoiling, the coil is conveyed to a metal leveling machine, where a series of mechanical actions straighten the material's surface, ensuring accuracy in subsequent processes. Then, the material is shaped into the desired final shape by the machine's rollers or molds. During this process, the metal ceiling machine precisely cuts the material to ensure that the dimensions and specifications of each finished sheet meet design requirements.

This type of metal ceiling machine is suitable for processing various metal materials, especially aluminum, iron, galvanized steel, and roll-coated steel. Whether in new building construction, renovation of old buildings, or site renewal projects, metal ceiling machines play a vital role. With the diversification of architectural design styles, the flexibility and efficiency of metal ceiling machines allow construction professionals greater freedom to realize their design concepts.

2. What are the Functions of Metal Ceiling Machine?

Metal ceiling machines are primarily used to process flat metal materials into various types of suspended ceilings for final application in ceiling construction. This equipment boasts multiple functions to meet the increasingly diverse needs of the construction industry.

● Surface Smoothing: Metal ceiling machines effectively smooth the surface of materials, laying the foundation for precision in subsequent processes. This ensures that each suspended ceiling panel not only meets various functional requirements but also achieves the set aesthetic standards.

● Forming Capability: This metal ceiling machine possesses excellent forming capabilities, quickly and accurately processing flat metal sheets into various required shapes. This flexibility allows designers to adjust according to project needs, realizing unique design concepts and ensuring the final product conforms to the overall architectural style and meets functional requirements.

● Punching Function: Metal ceiling machines can punch holes in the surface of the sheet material. This function enables design diversity and aesthetics while meeting various needs such as ventilation and lighting. By optimizing the punching position and size, designers can create ceilings that are both beautiful and practical, improving the utilization efficiency of interior spaces.

● Cutting Support: This metal ceiling machine supports pre-cutting and post-cutting to better suit production line projects under different conditions.

● Fixed-length cutting function: At the end of the production line, the metal ceiling machine features an advanced fixed-length cutting function, providing customers with more precise size selection. This function ensures that every part of the material meets design requirements, avoiding material waste due to inaccurate cutting, thereby reducing project costs and improving construction efficiency.

3. Customization and Modular Design

KINGREAL CEILING MACHINERY metal ceiling machines demonstrate a high level of technological advancement, particularly in customization capabilities. KINGREAL CEILING MACHINERY can design corresponding metal ceiling machines according to the production needs of various building projects. For example, for building projects requiring cleanliness, moisture resistance, and ease of cleaning, KINGREAL CEILING MACHINERY provides specialized metal ceiling tile production line. For renovation projects prioritizing good ventilation and easy maintenance, baffle ceiling machine and open cell ceiling machine are recommended. KINGREAL CEILING MACHINERY metal ceiling machines are also suitable for clients seeking strong sound absorption and a spacious, unconfined feel; these projects can be met through grilyato ceiling machine. Furthermore, for clients who prefer a modern minimalist style, KINGREAL CEILING MACHINERY linear strip ceiling machine perfectly complement their preference for clean lines and a no-main-light design.

In addition, KINGREAL CEILING MACHINERY metal ceiling machines offer the unique advantage of modular design, greatly enhancing production line flexibility. Manufacturers can freely add or remove components based on actual production needs, such as adding punching stations, metal sheet cleaning machine, and acoustical ceiling tile textile stick machine. This flexibility allows the production line to adapt to market changes and customer demands. Moreover, customers can choose a basic model when initially purchasing, and KINGREAL CEILING MACHINERY can equip the metal ceiling machine with additional components as business expands or project requirements change, thereby optimizing the overall performance and efficiency of the production line.

4.Different Technologies in Metal Ceiling Machines

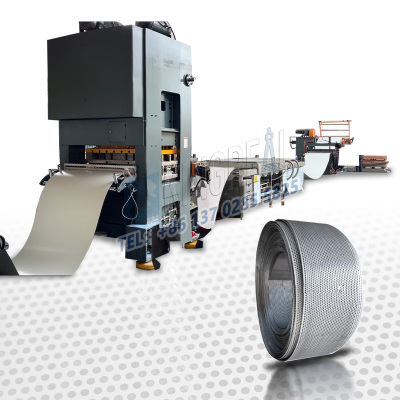

In the production process of suspended ceiling panels, although the processes may be similar, different types of metal ceiling machines exhibit significant differences in equipment configuration and technical processing. These differences are mainly reflected in the punching and forming processes.

●Punching Process for Metal Ceiling Machine

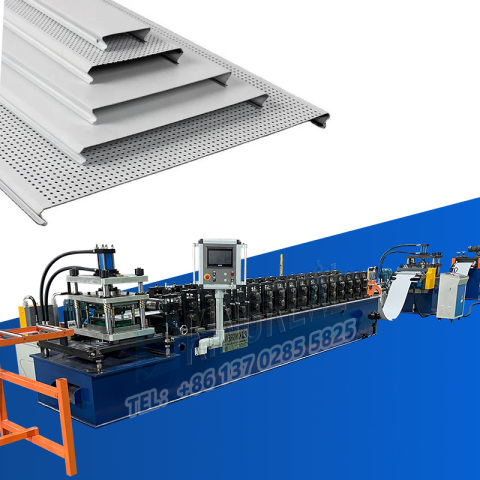

In the production process of suspended ceiling panels, the punching process plays a crucial role, providing the necessary holes and transparency to the ceiling panels, enhancing both aesthetics and functionality. Metal ceiling tile production lines and open cell ceiling machines are usually equipped with a perforation press, designed to handle high-volume production demands. The perforation press uses high-pressure mechanical force to precisely punch the metal sheets, creating the required hole diameters and shapes. In linear strip ceiling machines, when customers have specific production requirements, such as needing perforated linear strip ceilings, KINGREAL engineers configure the linear strip ceiling machine with a dedicated punching station. This flexible configuration makes the production line more adaptable, allowing for timely adjustments to the production process based on different market demands.

●Forming Process for Metal Ceiling Machine

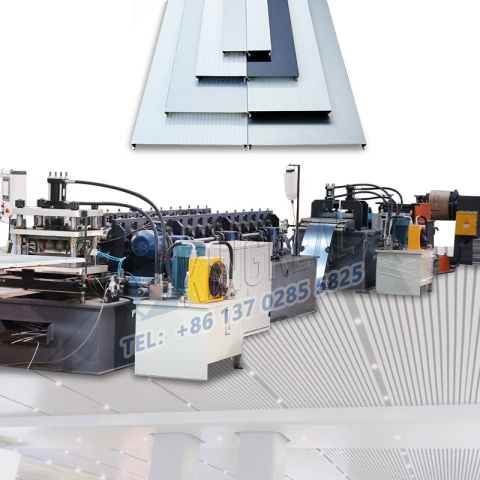

Equally important is the forming process, which directly affects the final shape and quality of the product. In the production line of metal ceiling panels, the automatic bending forming press used is highly precise. This equipment can press the four corners of the metal material and, by changing different molds, produce various types of metal ceiling panels suchs as clip-in, lay-in, and tegular. Open cell ceiling machines, baffle ceiling machines, and linear strip ceiling machines achieve material forming through a roll forming machine. In operation, the material is placed at the feeding position of the machine, and the rotation of the rollers is driven by a transmission device. The grooves and flanges on the rollers can be adjusted according to production needs to obtain different forming curves. In this process, the material gradually undergoes plastic deformation under the influence of the rollers, ultimately forming the predetermined shape.

Metal ceiling machines are primarily used for processing metal coils, and their application is becoming increasingly widespread, especially in the construction industry. The workflow of such machines typically involves several key steps. First, the metal coil is fed into a decoiler, where the material is unwound to facilitate subsequent processing. After uncoiling, the coil is conveyed to a metal leveling machine, where a series of mechanical actions straighten the material's surface, ensuring accuracy in subsequent processes. Then, the material is shaped into the desired final shape by the machine's rollers or molds. During this process, the metal ceiling machine precisely cuts the material to ensure that the dimensions and specifications of each finished sheet meet design requirements.

This type of metal ceiling machine is suitable for processing various metal materials, especially aluminum, iron, galvanized steel, and roll-coated steel. Whether in new building construction, renovation of old buildings, or site renewal projects, metal ceiling machines play a vital role. With the diversification of architectural design styles, the flexibility and efficiency of metal ceiling machines allow construction professionals greater freedom to realize their design concepts.

2. What are the Functions of Metal Ceiling Machine?

Metal ceiling machines are primarily used to process flat metal materials into various types of suspended ceilings for final application in ceiling construction. This equipment boasts multiple functions to meet the increasingly diverse needs of the construction industry.

● Surface Smoothing: Metal ceiling machines effectively smooth the surface of materials, laying the foundation for precision in subsequent processes. This ensures that each suspended ceiling panel not only meets various functional requirements but also achieves the set aesthetic standards.

● Forming Capability: This metal ceiling machine possesses excellent forming capabilities, quickly and accurately processing flat metal sheets into various required shapes. This flexibility allows designers to adjust according to project needs, realizing unique design concepts and ensuring the final product conforms to the overall architectural style and meets functional requirements.

● Punching Function: Metal ceiling machines can punch holes in the surface of the sheet material. This function enables design diversity and aesthetics while meeting various needs such as ventilation and lighting. By optimizing the punching position and size, designers can create ceilings that are both beautiful and practical, improving the utilization efficiency of interior spaces.

● Cutting Support: This metal ceiling machine supports pre-cutting and post-cutting to better suit production line projects under different conditions.

● Fixed-length cutting function: At the end of the production line, the metal ceiling machine features an advanced fixed-length cutting function, providing customers with more precise size selection. This function ensures that every part of the material meets design requirements, avoiding material waste due to inaccurate cutting, thereby reducing project costs and improving construction efficiency.

3. Customization and Modular Design

KINGREAL CEILING MACHINERY metal ceiling machines demonstrate a high level of technological advancement, particularly in customization capabilities. KINGREAL CEILING MACHINERY can design corresponding metal ceiling machines according to the production needs of various building projects. For example, for building projects requiring cleanliness, moisture resistance, and ease of cleaning, KINGREAL CEILING MACHINERY provides specialized metal ceiling tile production line. For renovation projects prioritizing good ventilation and easy maintenance, baffle ceiling machine and open cell ceiling machine are recommended. KINGREAL CEILING MACHINERY metal ceiling machines are also suitable for clients seeking strong sound absorption and a spacious, unconfined feel; these projects can be met through grilyato ceiling machine. Furthermore, for clients who prefer a modern minimalist style, KINGREAL CEILING MACHINERY linear strip ceiling machine perfectly complement their preference for clean lines and a no-main-light design.

In addition, KINGREAL CEILING MACHINERY metal ceiling machines offer the unique advantage of modular design, greatly enhancing production line flexibility. Manufacturers can freely add or remove components based on actual production needs, such as adding punching stations, metal sheet cleaning machine, and acoustical ceiling tile textile stick machine. This flexibility allows the production line to adapt to market changes and customer demands. Moreover, customers can choose a basic model when initially purchasing, and KINGREAL CEILING MACHINERY can equip the metal ceiling machine with additional components as business expands or project requirements change, thereby optimizing the overall performance and efficiency of the production line.

4.Different Technologies in Metal Ceiling Machines

In the production process of suspended ceiling panels, although the processes may be similar, different types of metal ceiling machines exhibit significant differences in equipment configuration and technical processing. These differences are mainly reflected in the punching and forming processes.

●Punching Process for Metal Ceiling Machine

In the production process of suspended ceiling panels, the punching process plays a crucial role, providing the necessary holes and transparency to the ceiling panels, enhancing both aesthetics and functionality. Metal ceiling tile production lines and open cell ceiling machines are usually equipped with a perforation press, designed to handle high-volume production demands. The perforation press uses high-pressure mechanical force to precisely punch the metal sheets, creating the required hole diameters and shapes. In linear strip ceiling machines, when customers have specific production requirements, such as needing perforated linear strip ceilings, KINGREAL engineers configure the linear strip ceiling machine with a dedicated punching station. This flexible configuration makes the production line more adaptable, allowing for timely adjustments to the production process based on different market demands.

●Forming Process for Metal Ceiling Machine

Equally important is the forming process, which directly affects the final shape and quality of the product. In the production line of metal ceiling panels, the automatic bending forming press used is highly precise. This equipment can press the four corners of the metal material and, by changing different molds, produce various types of metal ceiling panels suchs as clip-in, lay-in, and tegular. Open cell ceiling machines, baffle ceiling machines, and linear strip ceiling machines achieve material forming through a roll forming machine. In operation, the material is placed at the feeding position of the machine, and the rotation of the rollers is driven by a transmission device. The grooves and flanges on the rollers can be adjusted according to production needs to obtain different forming curves. In this process, the material gradually undergoes plastic deformation under the influence of the rollers, ultimately forming the predetermined shape.

-

Catalogs:

-

![Aluminum Strip Ceiling Panel Machine]()

Aluminum Strip Ceiling Panel Machine

-

![Wall Cladding Panel Production Line]()

Wall Cladding Panel Production Line

-

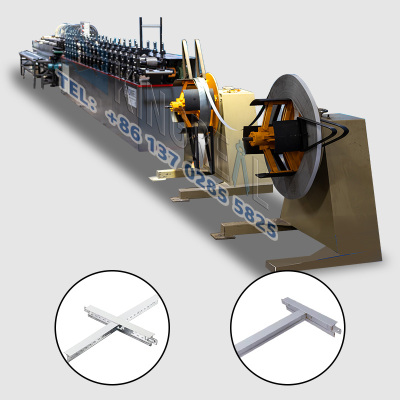

![Grilyato Ceiling Machine]()

Grilyato Ceiling Machine

-

![Suspended Ceiling Linear Strip Ceiling Machine]()

Suspended Ceiling Linear Strip Ceiling Machine

-

![U10 U15 Open Cell Ceiling Machine]()

U10 U15 Open Cell Ceiling Machine

-

![Linear Strip Ceiling Auto Production Line]()

Linear Strip Ceiling Auto Production Line

-

![Linear Strip Ceiling Machine]()

Linear Strip Ceiling Machine

-

![120X60CM Metal Ceiling Tiles Production Line]()

120X60CM Metal Ceiling Tiles Production Line

-

![Clip In Metal Ceiling Tile Production Line]()

Clip In Metal Ceiling Tile Production Line

-

![Lay In Aluminum Ceiling Tile Production Line]()

Lay In Aluminum Ceiling Tile Production Line

-

![Full Automatic 30X30CM Metal Ceiling Tiles Making Machine]()

Full Automatic 30X30CM Metal Ceiling Tiles Making Machine

-

![U Baffle Ceiling Production Line]()

U Baffle Ceiling Production Line

Get the latest price? We'll respond as soon as possible(within 12 hours)