- Home

- >

- Products

- >

- Roll Forming Machine

- >

Products Lists

01.What is the Process of Roll Forming?

Roll forming is a process in which a strip of material is bent in a small and controlled manner using a series of precision rollers until it reaches the desired final shape. This process is widely used due to its high efficiency and precision. A complete roll forming machine typically includes multiple precision components such as a decoiler, leveler, main roll forming machine, cutting station, and output table, working together to achieve the best forming effect. In the production process, the material is first unwound by the decoiler, gradually straightening the coil. Next, the material is leveled by the rollers of the leveler to ensure a smooth and flat surface, and then conveyed to the roll forming machine. In the roll forming machine, the material passes through a series of rolling stations, where the degree of bending gradually increases. Each small bend gradually shapes the material into the desired shape. Finally, the material is cut to the required length by the cutting station, completing the production process.

02.What are the Applications of Roll Forming?

Roll forming machines are widely used in various industries. The type and design of the roll forming machine vary depending on the needs of different fields. KINGREAL CEILING MACHINERY primarily provides professional roll forming machine solutions for suspended ceiling and ventilation systems.

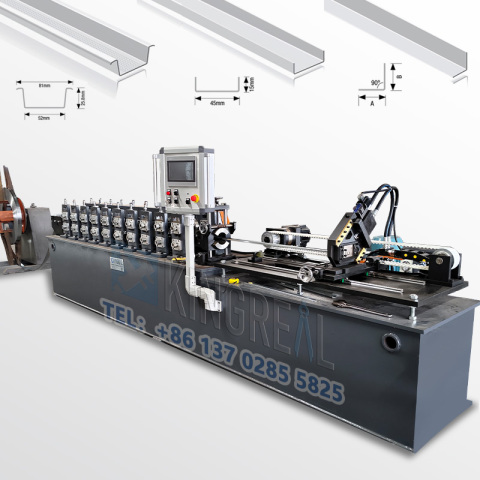

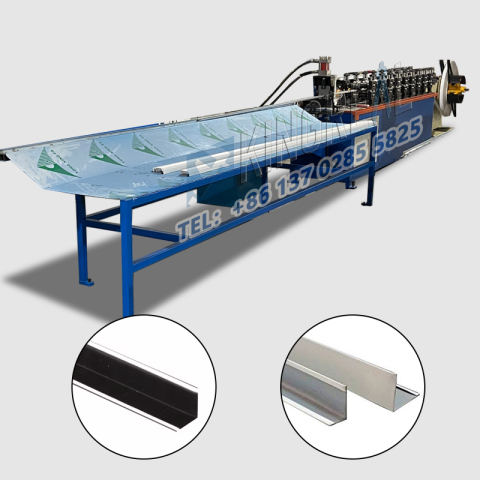

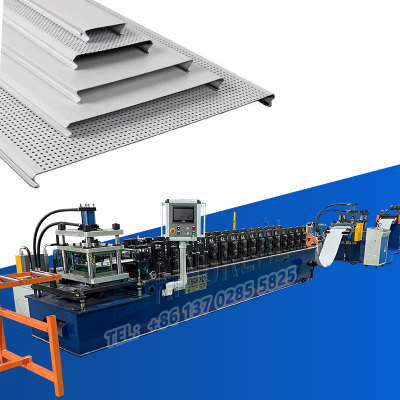

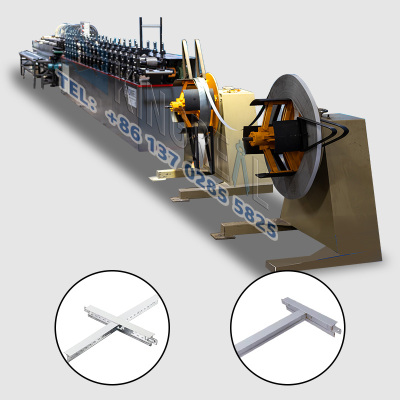

●Roll forming machines for suspended ceiling system

In suspended ceiling installations, ceiling t bar and suspended ceiling are commonly used support structures. Ceiling t bar machines can produce various types of ceiling t bar, including flat ceiling t bar, center black line t grid, FUT ceiling t bar, and groove ceiling t bar. These products are used for assembly with lay-in or open cell ceilings, offering fire resistance, moisture resistance, and easy disassembly. This flexibility simplifies installation and maintenance, adapting to changing environmental needs. False ceiling channel machines can produce hat channels, u channels, and wall angles for use with gypsum board. These false ceiling channel machines can produce up to 120m/min, ensuring efficient and high-precision production. These profiles create a stable, flat, and durable structural frame, providing reliable support for gypsum board installation. Gypsum board can be easily installed on the joists using screws or clips, enabling convenient construction.

●Roll forming machines for ventilation system

KINGREAL CEILING MACHINERY also offers a range of roll forming machines for constructing ventilation systems, including fire damper frame machines, fire damper blade machine, tdc flange machine, and tdf flange machine. The finished products produced by these roll forming machines form the core of the ventilation system, creating efficient airflow channels through precise assembly and connection, ensuring air quality and comfort in factories and buildings. The combination of fire damper frames and blades effectively prevents the spread of flames and smoke in ventilation ducts, ensuring safety. Meanwhile, TDC and TDF flanges provide a robust connection, ensuring the ventilation system maintains good sealing performance over long-term use, preventing air leakage and energy waste.

03.Challenges and Solutions in Roll Forming Machines

Although roll forming machines offer many advantages, they also face numerous challenges in design and use. Safety hazards are a significant issue. Accidental contact with the running rollers during roll forming machine operation can cause serious injury. Therefore, some countries mandate the installation of safety devices on these machines to improve safety performance. To address this challenge, KINGREAL CEILING MACHINERY designed a protective shield for the roll forming machine, ensuring it remains closed while the machine is running, but easily accessible for routine maintenance and cleaning.

Another challenge is die wear, especially when processing abrasive materials. Die life is affected by the materials used and the maintenance methods. Improper maintenance or the use of unsuitable materials can significantly shorten die life. To address this, KINGREAL CEILING MACHINERY developed harder, more wear-resistant die materials and employed an advanced lubrication system to reduce friction and wear during the forming process.

Furthermore, material thickness, budget constraints, and shearing speed also pose challenges to the roll forming machine. To address these issues, KINGREAL CEILING MACHINERY designed a swing shearing, fly shearing, and fixed shearing for the roll forming machine's cutting system. Each shearing method has its advantages and adapts to different production needs. The fly shearing and swing shearing offer faster shearing speeds, while the stationary shear stops the roll forming machine during shearing, resulting in a relatively slower speed.

04.Set up for Roll Forming Machine

Successfully starting and operating a roll forming machine involves several steps: preparation, startup, processing. The following are detailed instructions for these steps:

1)Preparation: First, ensure the roll forming machine is stopped and the power is disconnected. Then, check all parts of the roll forming machine for damage and ensure there are no defects. Clean the machine surface and remove debris to avoid interference in subsequent operations. Simultaneously, prepare the necessary raw materials, ensuring their quality meets production requirements.

2) Starting the roll forming machine: Next, connect the power supply correctly according to the machine's instruction manual and turn on the power switch. Then, start the roll forming machine as instructed in the manual and adjust relevant parameters, such as temperature and pressure, according to the required product specifications to ensure the machine operates at its optimal condition.

3) Processing Operation: After the machine is started, put the raw materials into the roll forming machine's feed inlet, ensuring the inlet is properly sealed. Adjust the roll forming machine's operating mode and speed according to product requirements. During processing, continuously observe the machine's operating status to ensure no abnormalities occur. Regularly check parameters such as temperature and pressure to ensure they are within normal operating ranges. If any abnormalities or malfunctions are found, immediately stop the machine and report to relevant personnel for handling.

Roll forming is a process in which a strip of material is bent in a small and controlled manner using a series of precision rollers until it reaches the desired final shape. This process is widely used due to its high efficiency and precision. A complete roll forming machine typically includes multiple precision components such as a decoiler, leveler, main roll forming machine, cutting station, and output table, working together to achieve the best forming effect. In the production process, the material is first unwound by the decoiler, gradually straightening the coil. Next, the material is leveled by the rollers of the leveler to ensure a smooth and flat surface, and then conveyed to the roll forming machine. In the roll forming machine, the material passes through a series of rolling stations, where the degree of bending gradually increases. Each small bend gradually shapes the material into the desired shape. Finally, the material is cut to the required length by the cutting station, completing the production process.

02.What are the Applications of Roll Forming?

Roll forming machines are widely used in various industries. The type and design of the roll forming machine vary depending on the needs of different fields. KINGREAL CEILING MACHINERY primarily provides professional roll forming machine solutions for suspended ceiling and ventilation systems.

●Roll forming machines for suspended ceiling system

In suspended ceiling installations, ceiling t bar and suspended ceiling are commonly used support structures. Ceiling t bar machines can produce various types of ceiling t bar, including flat ceiling t bar, center black line t grid, FUT ceiling t bar, and groove ceiling t bar. These products are used for assembly with lay-in or open cell ceilings, offering fire resistance, moisture resistance, and easy disassembly. This flexibility simplifies installation and maintenance, adapting to changing environmental needs. False ceiling channel machines can produce hat channels, u channels, and wall angles for use with gypsum board. These false ceiling channel machines can produce up to 120m/min, ensuring efficient and high-precision production. These profiles create a stable, flat, and durable structural frame, providing reliable support for gypsum board installation. Gypsum board can be easily installed on the joists using screws or clips, enabling convenient construction.

●Roll forming machines for ventilation system

KINGREAL CEILING MACHINERY also offers a range of roll forming machines for constructing ventilation systems, including fire damper frame machines, fire damper blade machine, tdc flange machine, and tdf flange machine. The finished products produced by these roll forming machines form the core of the ventilation system, creating efficient airflow channels through precise assembly and connection, ensuring air quality and comfort in factories and buildings. The combination of fire damper frames and blades effectively prevents the spread of flames and smoke in ventilation ducts, ensuring safety. Meanwhile, TDC and TDF flanges provide a robust connection, ensuring the ventilation system maintains good sealing performance over long-term use, preventing air leakage and energy waste.

03.Challenges and Solutions in Roll Forming Machines

Although roll forming machines offer many advantages, they also face numerous challenges in design and use. Safety hazards are a significant issue. Accidental contact with the running rollers during roll forming machine operation can cause serious injury. Therefore, some countries mandate the installation of safety devices on these machines to improve safety performance. To address this challenge, KINGREAL CEILING MACHINERY designed a protective shield for the roll forming machine, ensuring it remains closed while the machine is running, but easily accessible for routine maintenance and cleaning.

Another challenge is die wear, especially when processing abrasive materials. Die life is affected by the materials used and the maintenance methods. Improper maintenance or the use of unsuitable materials can significantly shorten die life. To address this, KINGREAL CEILING MACHINERY developed harder, more wear-resistant die materials and employed an advanced lubrication system to reduce friction and wear during the forming process.

Furthermore, material thickness, budget constraints, and shearing speed also pose challenges to the roll forming machine. To address these issues, KINGREAL CEILING MACHINERY designed a swing shearing, fly shearing, and fixed shearing for the roll forming machine's cutting system. Each shearing method has its advantages and adapts to different production needs. The fly shearing and swing shearing offer faster shearing speeds, while the stationary shear stops the roll forming machine during shearing, resulting in a relatively slower speed.

04.Set up for Roll Forming Machine

Successfully starting and operating a roll forming machine involves several steps: preparation, startup, processing. The following are detailed instructions for these steps:

1)Preparation: First, ensure the roll forming machine is stopped and the power is disconnected. Then, check all parts of the roll forming machine for damage and ensure there are no defects. Clean the machine surface and remove debris to avoid interference in subsequent operations. Simultaneously, prepare the necessary raw materials, ensuring their quality meets production requirements.

2) Starting the roll forming machine: Next, connect the power supply correctly according to the machine's instruction manual and turn on the power switch. Then, start the roll forming machine as instructed in the manual and adjust relevant parameters, such as temperature and pressure, according to the required product specifications to ensure the machine operates at its optimal condition.

3) Processing Operation: After the machine is started, put the raw materials into the roll forming machine's feed inlet, ensuring the inlet is properly sealed. Adjust the roll forming machine's operating mode and speed according to product requirements. During processing, continuously observe the machine's operating status to ensure no abnormalities occur. Regularly check parameters such as temperature and pressure to ensure they are within normal operating ranges. If any abnormalities or malfunctions are found, immediately stop the machine and report to relevant personnel for handling.

Get the latest price? We'll respond as soon as possible(within 12 hours)